Ferroelectric film, ferroelectric capacitor, ferroelectric memory, piezoelectric element, semiconductor element, method of manufacturing ferroelectric film, and method of manufacturing ferroelectric capacitor

a manufacturing method and technology of ferroelectric film, applied in the field of ferroelectric capacitors, ferroelectric capacitors, piezoelectric elements, etc., can solve the problems of lack of reliability, difficult to ensure reliability, and inability to provide a ten-year guarantee, and achieve the effect of satisfying characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

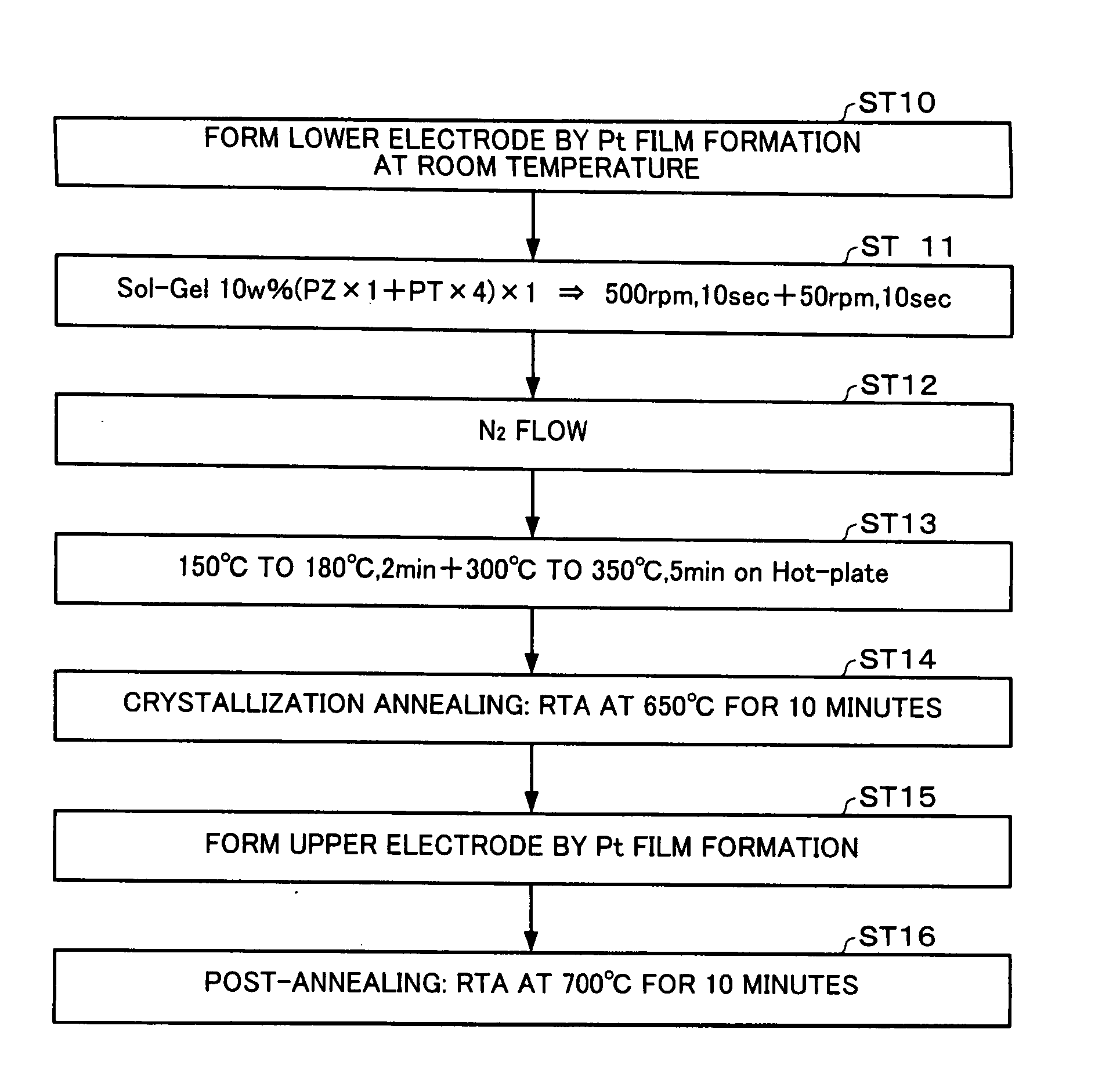

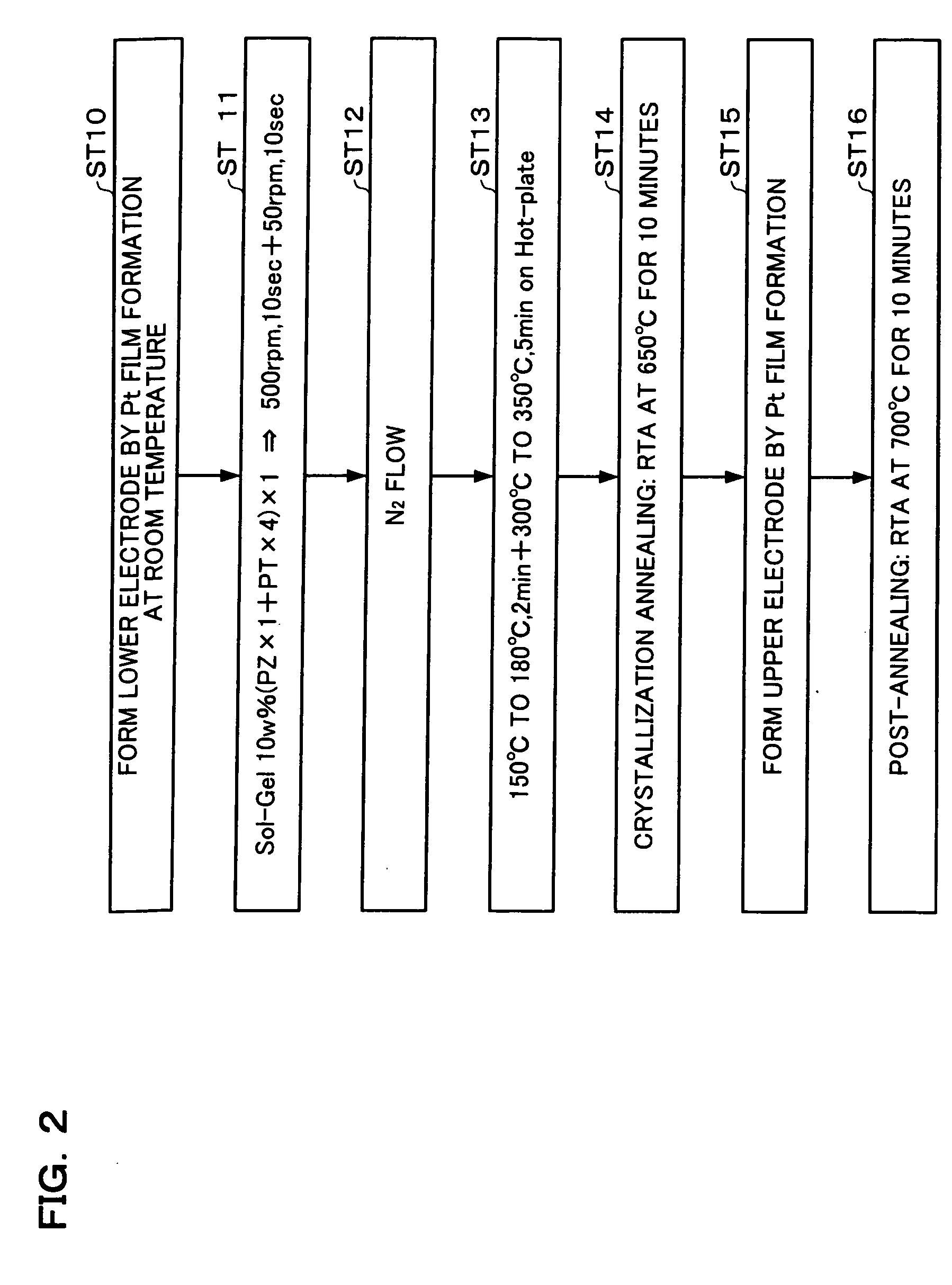

[0121] This embodiment compares the PZTN of the present invention and the PZT of the conventional art. The entire film formation flow shown in FIG. 2 was used.

[0122] Ratios of Pb:Zr:Ti:Nb=1:0.2:0.6:0.2, 1:0.2:0.7:0.1, and 1:0.3:0.65:0.5 were used. In other words, the total quantity of added Nb is 5 to 20 mol %. In this case, 0 to 1% of PbSiO3 is added.

[0123] The surface morphologies of the films in this case are shown in FIGS. 4A to 4C. When the crystallinity of these films were measured by an X-ray diffraction method, the results were as shown in FIGS. 5A to 5C. With the 0% (none) case shown in FIG. 5A, only ordinary paraelectric pyrochlore is obtained, even when the crystallization temperature rises to 800° C. With the 0.5% case shown in FIG. 5B, PZT and the pyrochlore are mixed. With the 1% case shown in FIG. 5C, a single orientated film of PZT (111) is obtained. The crystallinity thereof is also good, of a quality that can not be achieved up to now.

[0124] Next, the crystallin...

second embodiment

[0131] This embodiment is a comparison of the ferroelectric characteristics obtained when the amount of Nb added to the PZTN ferroelectric film was varied to 0, 5, 10, 20, 30, 40 mol %. 5 mol % of PbSiO3 was added to all the testpieces. In addition, methyl succinate was added to the sol-gel solutions for forming the ferroelectric films, includes of raw materials for film formation, to adjust the pH to 6. The entire film formation flow shown in FIG. 2 was used therefor.

[0132] Measured hysteresis characteristics of PZTN ferroelectric films in accordance with this embodiment are shown in FIGS. 17 to 19.

[0133]FIG. 17A shows that when the quantity of added Nb is 0, leaky hysteresis is obtained, whereas FIG. 17B shows that when the quantity of added Nb is 5 mol %, a good hysteresis characteristic with a high level of insulation is obtained.

[0134]FIG. 18A shows that substantially no change is seen in the ferroelectric characteristic until the quantity of added Nb reaches 10 mol %. Even ...

third embodiment

[0145] This embodiment investigates the validity of using a PZTN film from the viewpoint of lattice regularity, when the PZTN film has been formed on a metal film formed of a platinum-group metal such as Pt or Ir as an electrode material for a ferroelectric capacitor that forms a memory cell portion of ferroelectric memory or a piezoelectric actuator that configures an ink ejection nozzle portion of an inkjet printer, by way of example. Platinum-group metals act as underlayer films that determine the crystal orientation of ferroelectric films, and are also useful as electrode materials. However, since the lattice regularities of the two materials are not sufficient, a problem arises concerning the fatigue characteristics of ferroelectric films when applied to elements.

[0146] In this case, the present inventors have developed a technique designed to ameliorate lattice mismatches between a PZT-family ferroelectric film and a platinum-group metal thin film, by incorporating Nb into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| leakage current characteristics | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com