Bismuth titanate photocatalytic material with visible light response and preparation method thereof

A photocatalytic material, bismuth titanate technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of environmental protection, simple preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of bismuth titanate photocatalytic material with visible light response:

[0019] 1) Preparation of raw materials: Weigh the analytically pure TiO 2 and Bi 2 o 3 As a raw material, according to TiO 2 with Bi 2 o 3 The molar ratio of the mixture is 1:20 for batching, put the prepared raw materials into the mixer and mix evenly, the mixer speed is 200 rpm, and the mixing time is 2 hours;

[0020] 2) Heating reaction: put the mixture obtained in step 1) into a platinum crucible, then put the platinum crucible into a muffle furnace preheated to 900°C in advance, and react for 2 minutes;

[0021] 3) Quenching and cooling: take out the reacted platinum crucible and quickly put it into cold water for quenching, and grind the obtained sample finely in an agate mortar.

Embodiment 2

[0023] Preparation of bismuth titanate photocatalytic material with visible light response:

[0024] 1) Preparation of raw materials: Weigh the analytically pure TiO 2 and Bi 2 o 3 As a raw material, according to TiO 2 with Bi 2 o 3 The molar ratio of the mixture is 1:20 for batching, put the prepared raw materials into the mixer and mix evenly, the mixer speed is 200 rpm, and the mixing time is 2 hours;

[0025] 2) Heating reaction: put the mixture obtained in step 1) into a platinum crucible, then put the platinum crucible into a muffle furnace preheated to 900°C in advance, and react for 3 minutes;

[0026] 3) Quenching and cooling: take out the reacted platinum crucible and quickly put it into cold water for quenching, and grind the obtained sample finely in an agate mortar.

Embodiment 3

[0028] Preparation of bismuth titanate photocatalytic material with visible light response:

[0029] 1) Preparation of raw materials: Weigh the analytically pure TiO 2 and Bi 2 o 3 As a raw material, according to TiO 2 with Bi 2 o 3 The molar ratio of the mixture is 1:20 for batching, put the prepared raw materials into the mixer and mix evenly, the mixer speed is 200 rpm, and the mixing time is 2 hours;

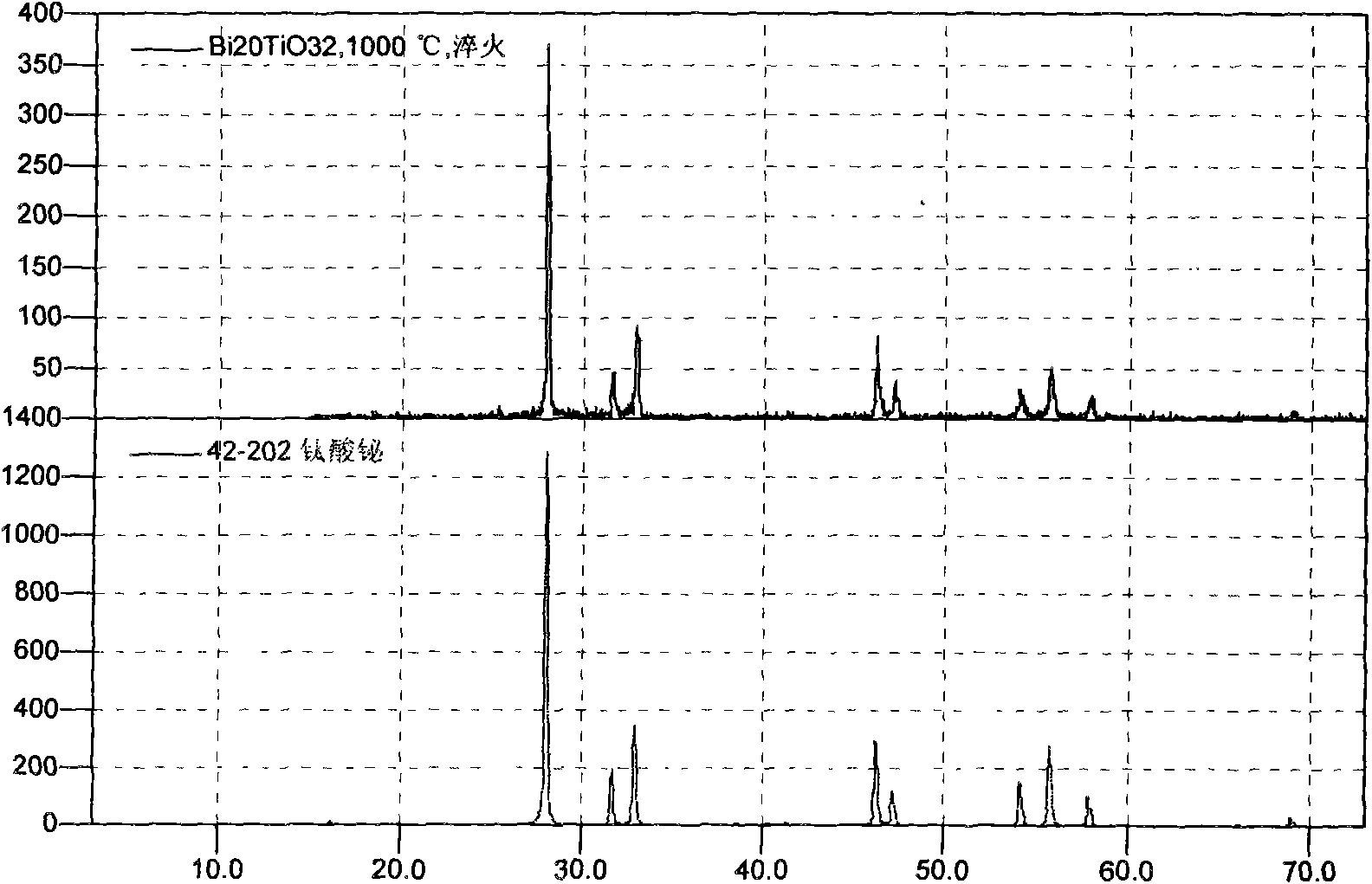

[0030] 2) Heating reaction: put the mixture obtained in step 1) into a platinum crucible, then put the platinum crucible into a muffle furnace preheated to 1000°C in advance, and react for 3 minutes;

[0031] 3) Quenching and cooling: take out the reacted platinum crucible and quickly put it into cold water for quenching, and grind the obtained sample finely in an agate mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com