Porous structured bismuth titanate microsphere, preparation method and application thereof

A porous structure, bismuth titanate technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of small specific surface area of materials, uncontrollable morphology, The preparation cost is high, and the preparation process is simple, the structure is easy to control, and the operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 3g surfactant F127 (EO 106 PO 70 EO 106 , Aldrich) was dissolved in 40ml deionized water, and 12g bismuth nitrate pentahydrate (0.025mol) was dissolved in 60ml glacial acetic acid, then the above two solutions were mixed and stirred evenly, 8.5ml n-butyl titanate (0.025mol) was added and Mix well to obtain a sprayed precursor solution.

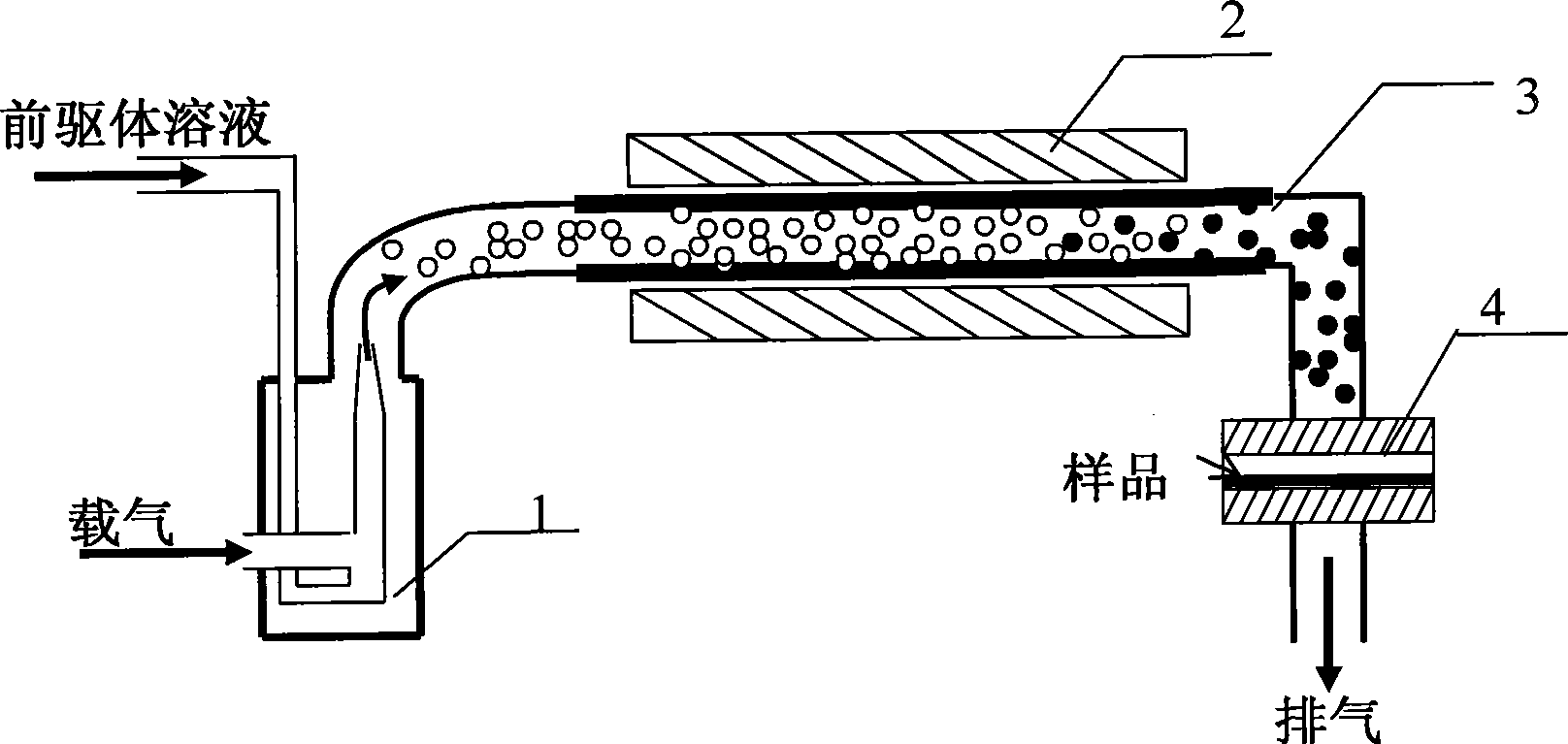

[0031] The structure of the spray drying equipment is as follows: figure 1 As shown, it includes an atomizer 1 , a tube furnace 2 , a quartz tube 3 and a filter 4 . The tube furnace jacket is used for heating outside the quartz tube. The outlet of the atomizer is connected to the quartz tube. The carrier gas and precursor solution are atomized and enter the quartz tube. The other end of the quartz tube is connected to the filter; the function of the filter is to collect Particles formed after spray drying.

[0032] Nitrogen was used as the carrier gas at a flow rate of 4 L / min. The solution was passed through the nebulizer to form ...

Embodiment 2

[0035] Dissolve 12g of bismuth nitrate pentahydrate in a mixed solution of 40ml of deionized water and 60ml of glacial acetic acid and stir until completely dissolved, and the rest of the steps are the same as described in Example 1.

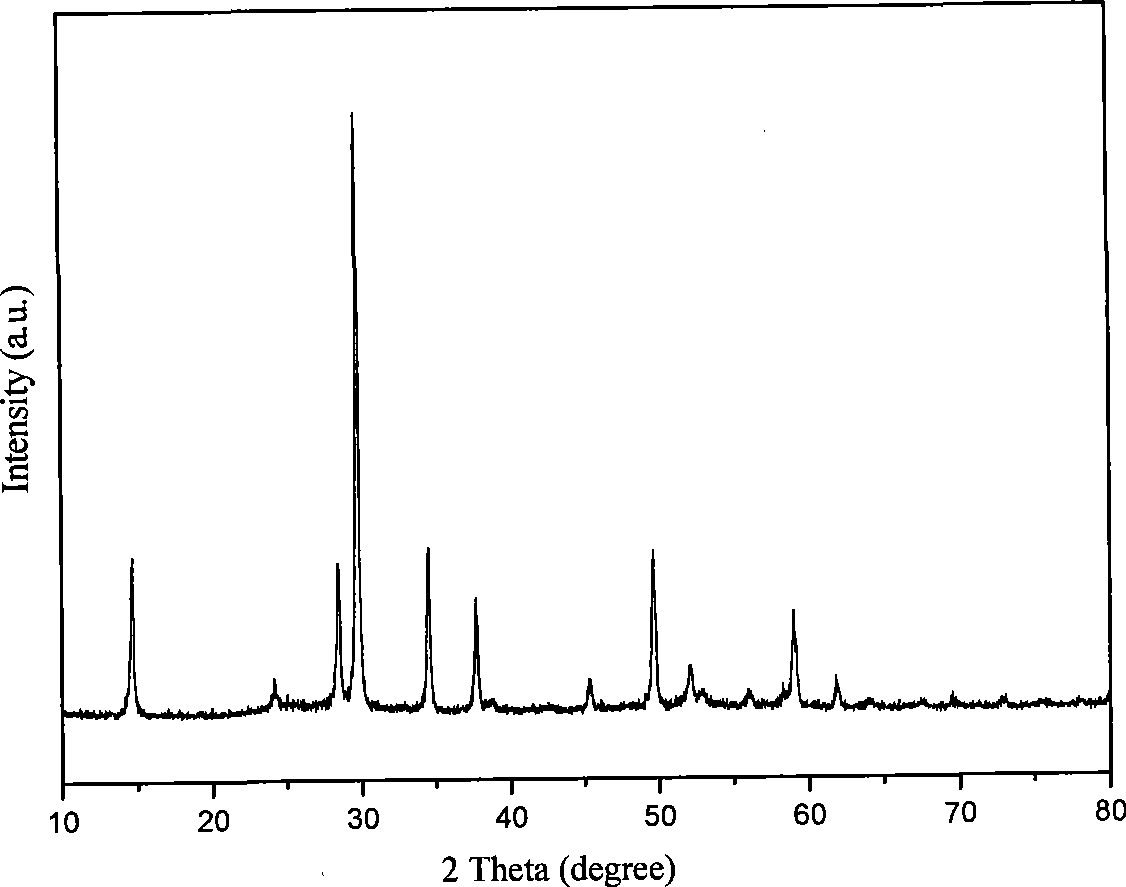

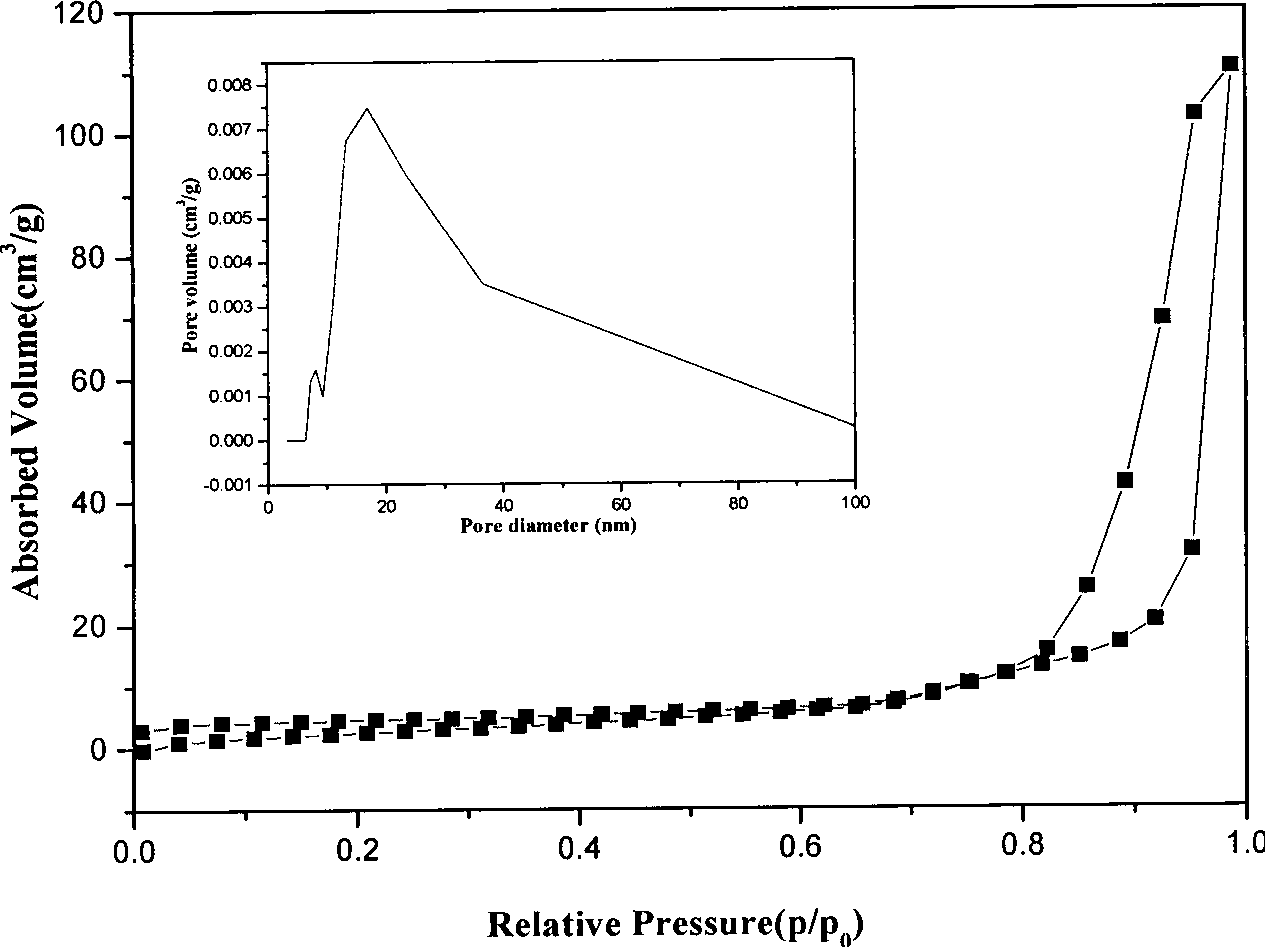

[0036] The obtained sample can be determined to be Bi by X-ray diffraction pattern 2 Ti 2 o 7 ; It can be determined that the obtained sample has a mesoporous structure through the nitrogen absorption-desorption isotherm, and the calculation shows that the pore diameter of the obtained sample is 17.8nm, and the pore volume is 0.06cm 3 / g, the specific surface area is 8.9m 2 / g; It can be seen by SEM scanning and TEM that the obtained sample is a microsphere with a porous structure, and the particle size is 0.5-2.0 μm.

Embodiment 3

[0038] 2g of surfactant F127 and 12g of bismuth nitrate pentahydrate were dissolved in 30ml of deionized water and 70ml of glacial acetic acid respectively, and the remaining contents were the same as those described in Example 1.

[0039] The obtained sample can be determined to be Bi by X-ray diffraction pattern 2 Ti 2 o 7 ; It can be determined that the obtained sample has a mesoporous structure through the nitrogen absorption-desorption isotherm, and the calculation shows that the pore diameter of the obtained sample is 23.6nm, and the pore volume is 0.09cm 3 / g, the specific surface area is 10.4m 2 / g; It can be seen by SEM and TEM that the obtained sample is a microsphere with a porous structure, and the particle size is 0.5-2.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com