Preparation method and application of single-phase bismuth titanate nano-material

A single-phase bismuth titanate and nanomaterial technology, applied in the fields of nanomaterials and environmental science and engineering, can solve the problems of harsh synthesis conditions and high synthesis temperature, and achieve the effects of low equipment cost, good regeneration performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

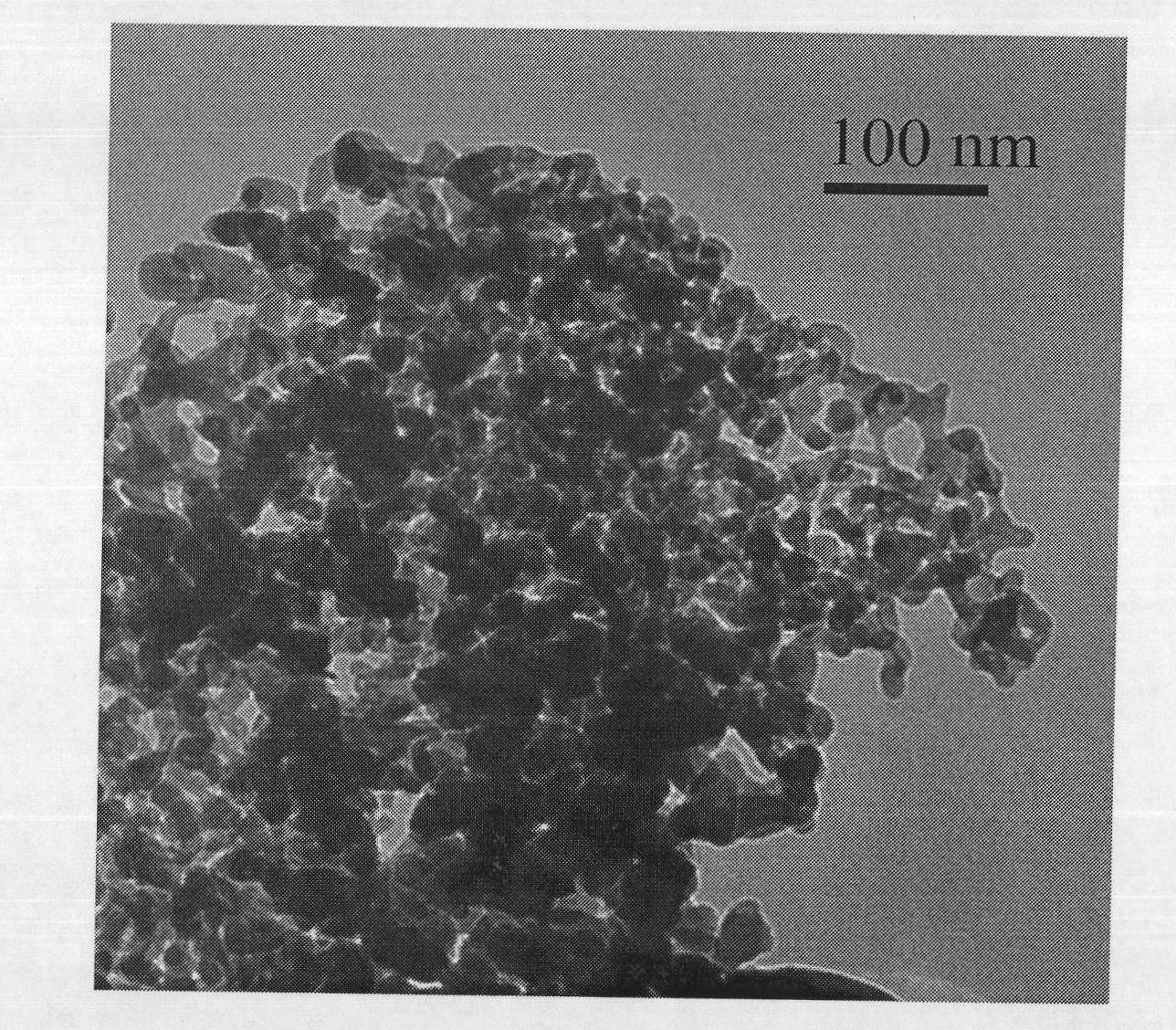

[0034] Weigh 8.0g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) join in the acetic acid, make the molar ratio of bismuth / carboxylate be 1: 55, stir continuously until the bismuth nitrate dissolves completely and then add tetrabutyl titanate dropwise therein, make the molar ratio of titanium / bismuth be 1: 10, After continuing to stir to obtain a clear solution, inject the structure-directing agent benzyl alcohol into it, so that the molar ratio of bismuth / alcohol is 1:3, and finally add urea to the above solution, so that the molar ratio of bismuth / urea is 1:1.5, and then stir until the solution is clear Transparent. Inject the prepared solution into 220mL ethanol solvent, mix evenly, move it into a high-pressure reactor, heat it to 200°C under the protection of 12bar nitrogen and keep it for 6h to completely hydrolyze or alcoholyze the bismuth nitrate, then open the vent valve to discharge solvent to obtain dry Bi 20 TiO 32 The precursor of nanomaterials, and then wash the precur...

Embodiment 2

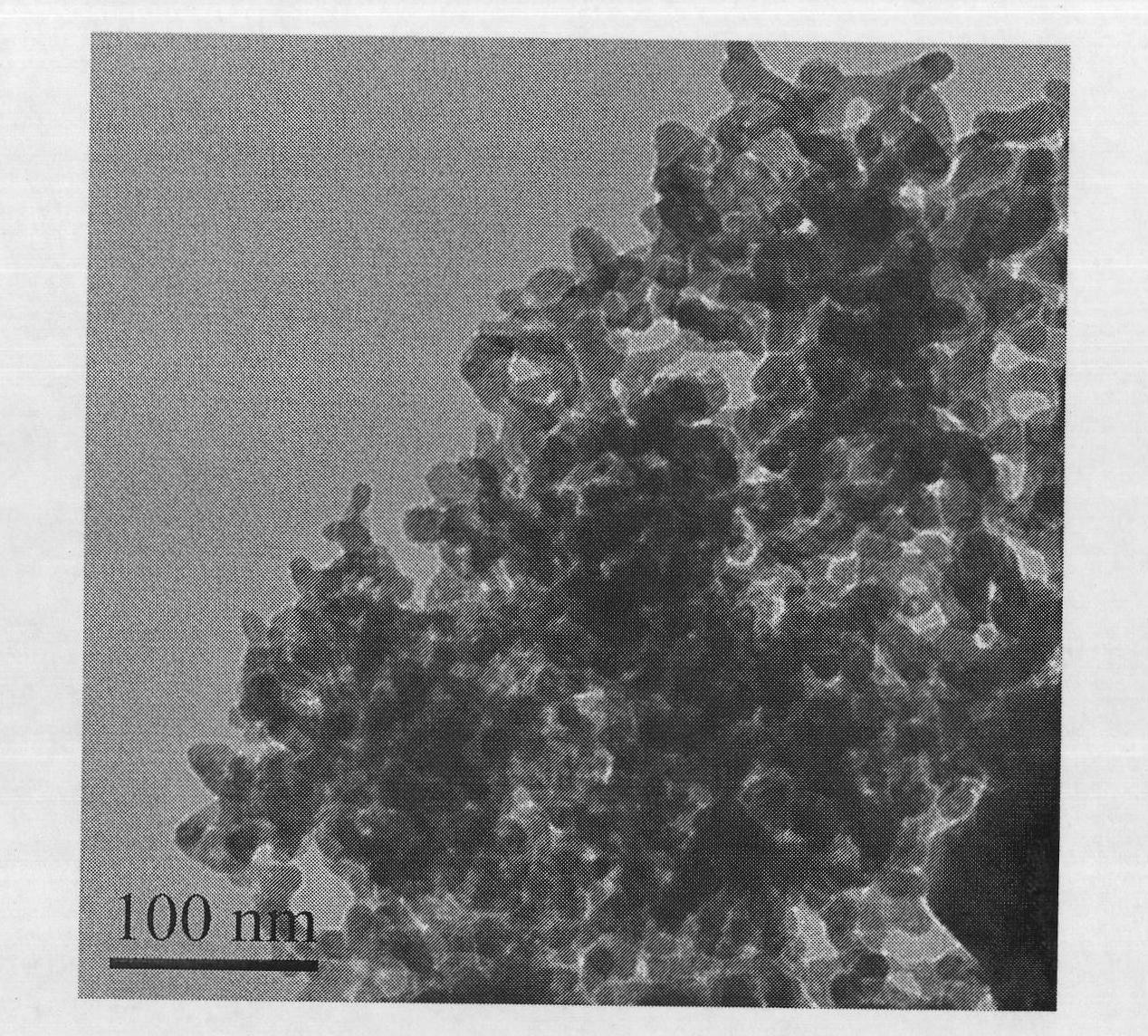

[0036] Weigh 8.0g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) Add in formic acid, make bismuth / carboxylate molar ratio be 1: 40, stir continuously until bismuth nitrate dissolves completely, then add tetraisopropyl titanate dropwise therein, make titanium / bismuth molar ratio be 1: 13 After continuing to stir to obtain a clear solution, inject structure-directing agent p-nitrobenzyl alcohol therein so that the bismuth / alcohol mol ratio is 1:4, and finally add urea to the above-mentioned solution so that the mol ratio of bismuth / urea is 1:2.2, Then stir until the solution is clear and transparent. Inject the prepared solution into 200mL of methanol solvent, mix it evenly, transfer it into a high-pressure reactor, and heat it to 235°C under the protection of 10bar nitrogen for 4 hours to completely hydrolyze or alcoholyze the bismuth nitrate, then open the vent valve to discharge solvent to obtain dry Bi 20 TiO 32 The precursor of nanomaterials, and then wash the precursor with et...

Embodiment 3

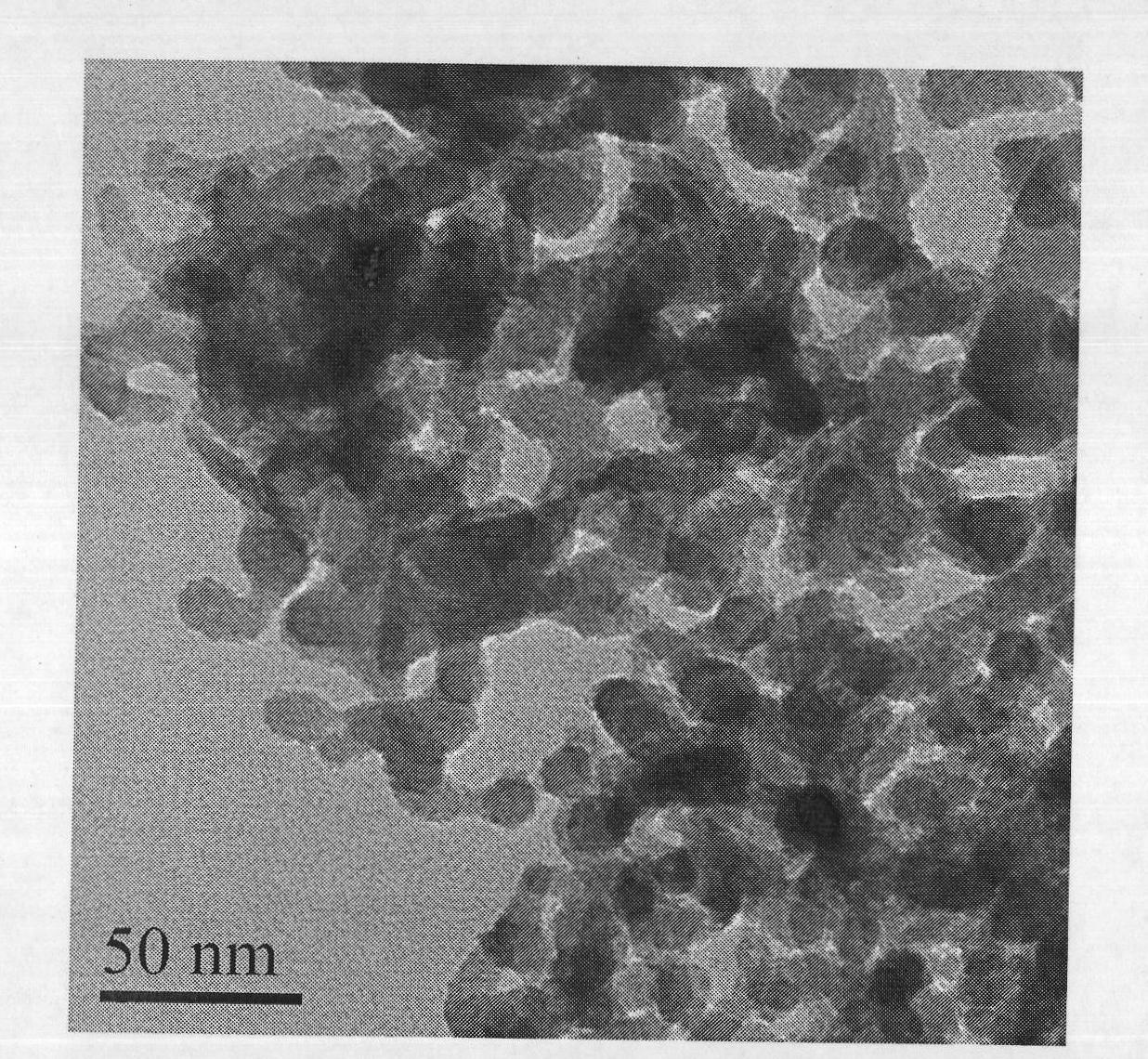

[0038] Weigh 10.0g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) join in propionic acid, make bismuth / carboxylate molar ratio be 1: 70, stir continuously until bismuth nitrate dissolves completely, then add tetrabutyl titanate dropwise therein, make titanium / bismuth molar ratio be 1: 8 After continuing to stir to obtain a clear solution, inject the structure-directing agent phenylethyl alcohol into it so that the molar ratio of bismuth / alcohol is 1:3, and finally add urea to the above solution so that the mol ratio of bismuth / urea is 1:3.5, and then stir until The solution is clear and transparent. Inject the prepared solution into 250mL propanol solvent, mix evenly, move it into a high-pressure reactor, and heat it to 240°C under the protection of 11bar nitrogen for 3 hours to completely hydrolyze or alcoholyze the bismuth nitrate, and then open the vent valve Drain the solvent to obtain dry Bi 20 TiO 32 The precursor of nanomaterials is washed three times with ethanol and deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com