Method for preparing porous bismuth titanate photocatalyst

A photocatalyst and bismuth titanate technology, applied in the field of environmental science and engineering, can solve the problems of unsolvable catalyst separation, small particle size, etc., and achieve good industrial application prospects, mild reaction conditions, and low requirements for reaction devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

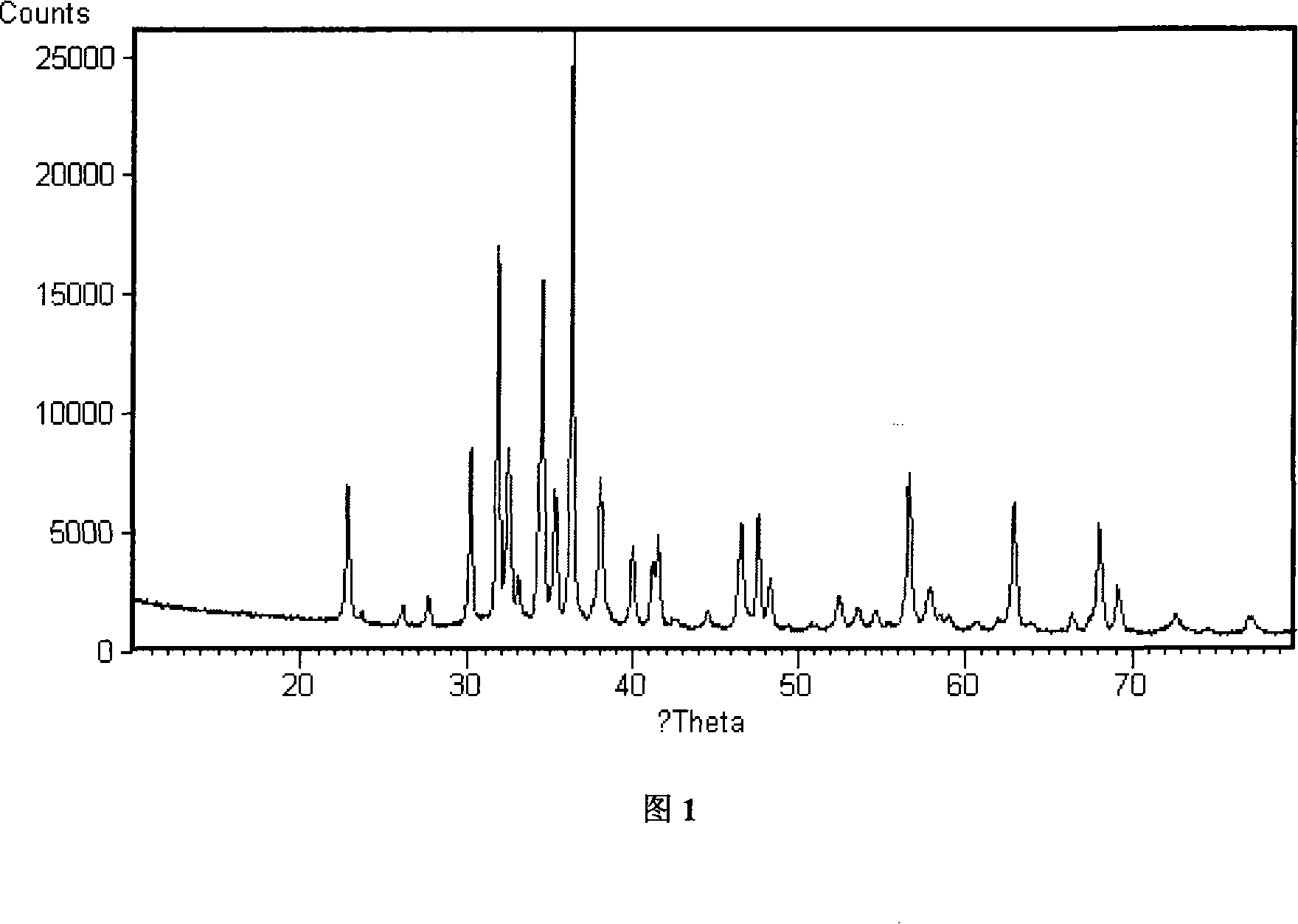

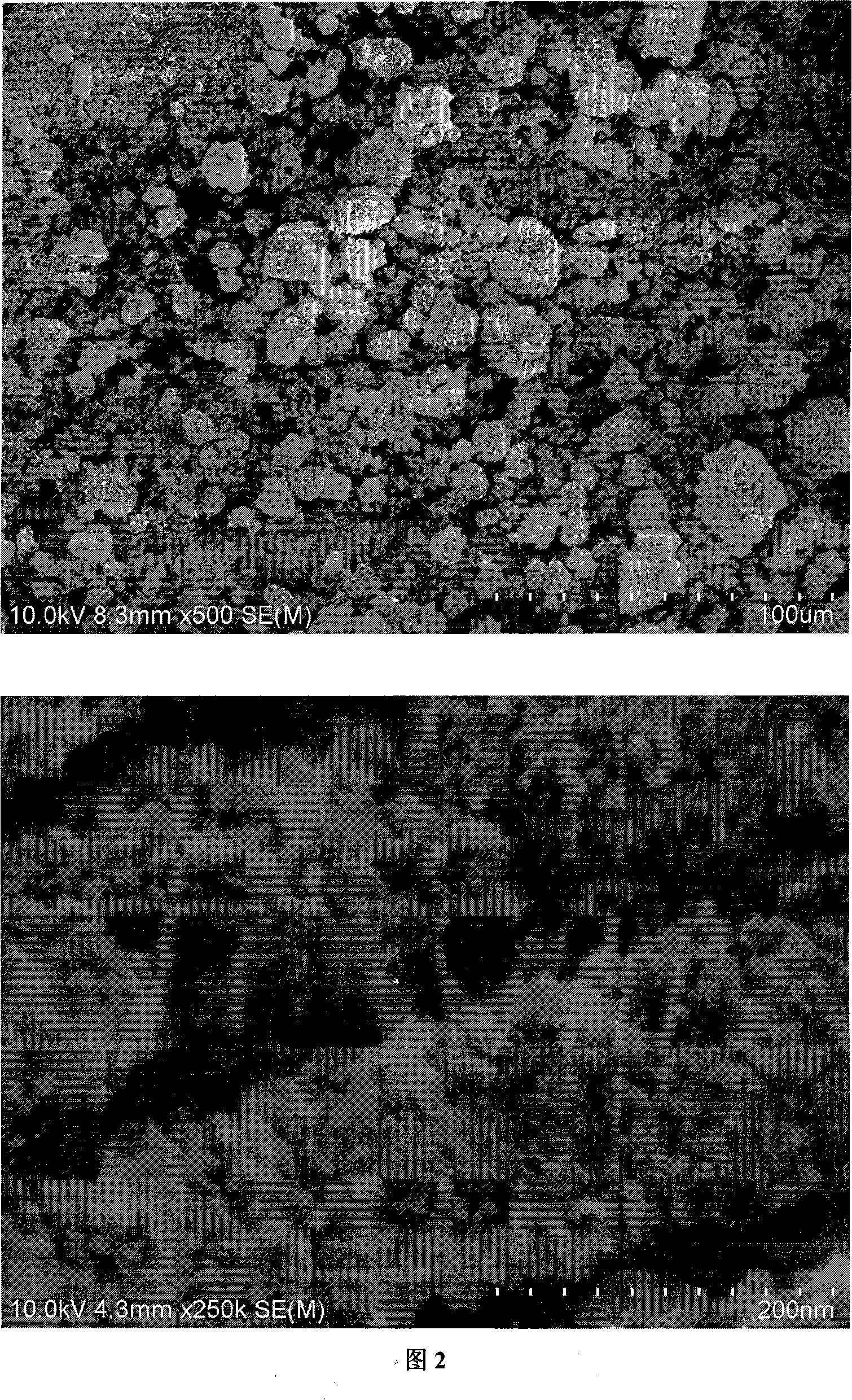

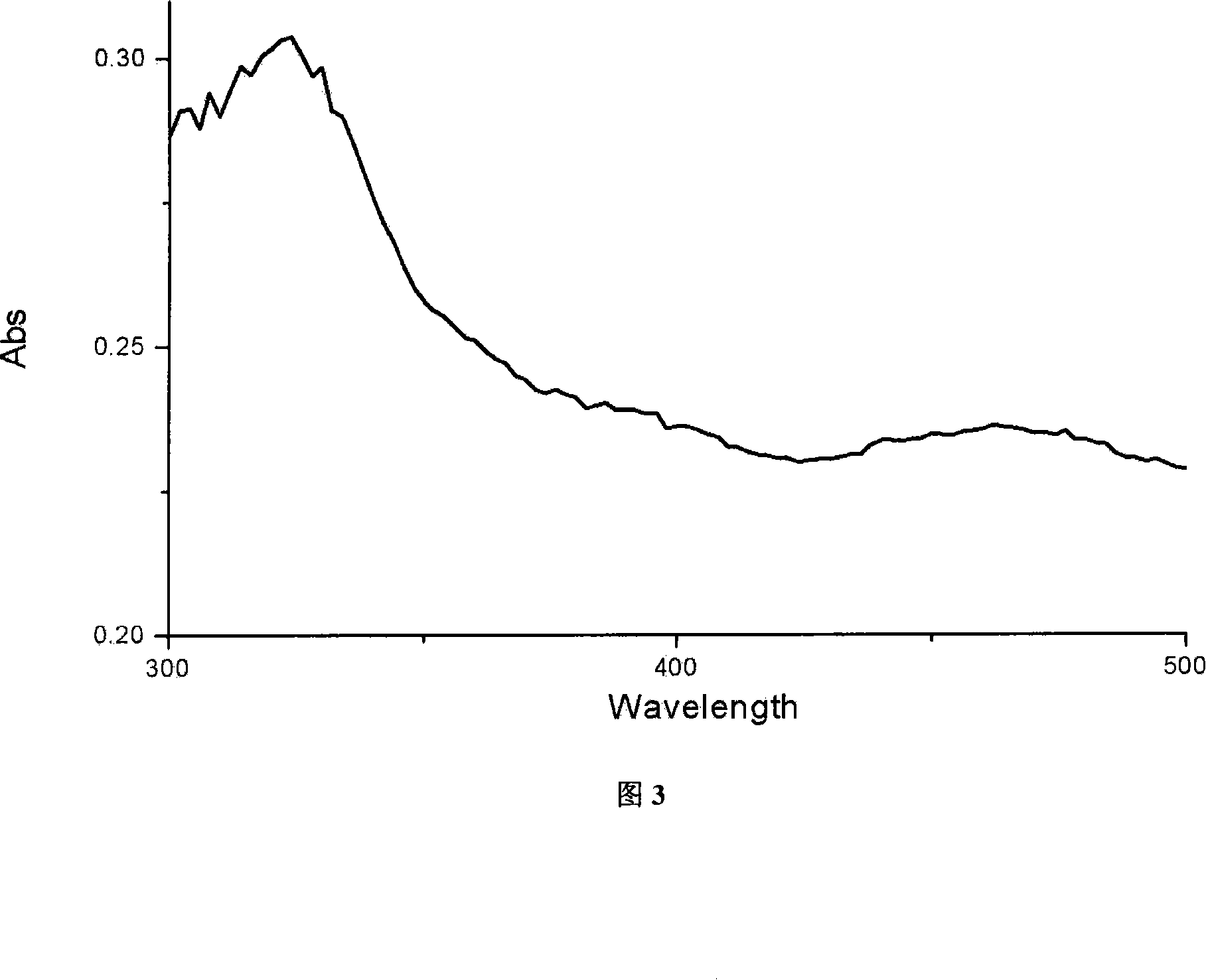

[0028] 5 g of P123 block copolymer surfactant was dissolved in 50 ml of acetic acid (CH 3 COOH) to form a solution with a concentration of 100 grams per liter, add 17 grams of bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), stirring constantly until completely dissolved, then adding 0.85 gram of tetrabutyl titanate (Ti(OC) dropwise 4 h 9 ) 4 ), the titanium / bismuth molar ratio is 1:14. Stir vigorously to form a homogeneous sol. After aging for 12 hours, move the aforementioned sol to an autoclave, crystallize at 150°C for 24 hours, take out the composite oxide gel precipitate, wash with deionized water, and evaporate and dry at 120°C to obtain titanium bismuth composite oxide things. The obtained precursor powder was calcined at a temperature of 550° C. for 3 hours in a normal-pressure air atmosphere to obtain a mesoporous bismuth titanate photocatalyst, which was designated as 1# sample. The sample was measured by the nitrogen adsorption-desorption specific surfac...

Embodiment 2

[0030]Dissolve 2.5 grams of F108 block copolymer surfactant in 50 milliliters of acetic acid to form a solution with a concentration of 50 grams per liter, add 17 grams of bismuth nitrate pentahydrate, stir continuously until completely dissolved, then add 0.71 grams of isopropyl titanate dropwise (Ti(OC 3 h 7 ) 4 ), the titanium / bismuth molar ratio is 1:14. Stir vigorously to form a homogeneous sol. After aging for 12 hours, the aforementioned sol was moved to an autoclave, crystallized at 140°C for 12 hours, the gel precipitate was taken out, washed, evaporated and dried at 140°C to obtain a titanium-bismuth composite oxide. The obtained precursor powder was calcined at a temperature of 550° C. for 3 hours in a normal-pressure air atmosphere to obtain a mesoporous bismuth titanate photocatalyst, which was designated as 2# sample. Its specific surface area is 25.4 square meters per gram, and its pore diameter is about 1.6 nanometers.

Embodiment 3

[0032] Dissolve 5 grams of P123 block copolymer surfactant in 50 milliliters of acetic acid to form a solution with a concentration of 100 grams per liter, add 17. grams of bismuth nitrate pentahydrate, stir continuously until completely dissolved, then add 0.88 grams of tetrabutyl titanate dropwise ester, at this time the molar ratio of titanium / bismuth is 1:13.5. Stir vigorously to form a homogeneous sol. After aging for 12 hours, the aforementioned sol was moved to an autoclave, crystallized at 150°C for 24 hours, the composite oxide gel precipitate was taken out, washed, evaporated and dried at 130°C to obtain a titanium-bismuth composite oxide. The obtained precursor powder was calcined at a temperature of 550° C. for 3 hours in a normal-pressure air atmosphere to obtain a mesoporous bismuth titanate photocatalyst, which was designated as 3# sample. Its specific surface area is 20.2 square meters per gram, and its pore diameter is about 1.7 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com