Preparation method of mesoporous MoS2/Sm2O3 photocatalyst

A photocatalyst and mesoporous technology, which is applied in the field of environmental science and engineering, can solve the problems of long step cycle and complicated preparation method, and achieve the effect of low requirement for reaction device, simple preparation process and good industrial application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

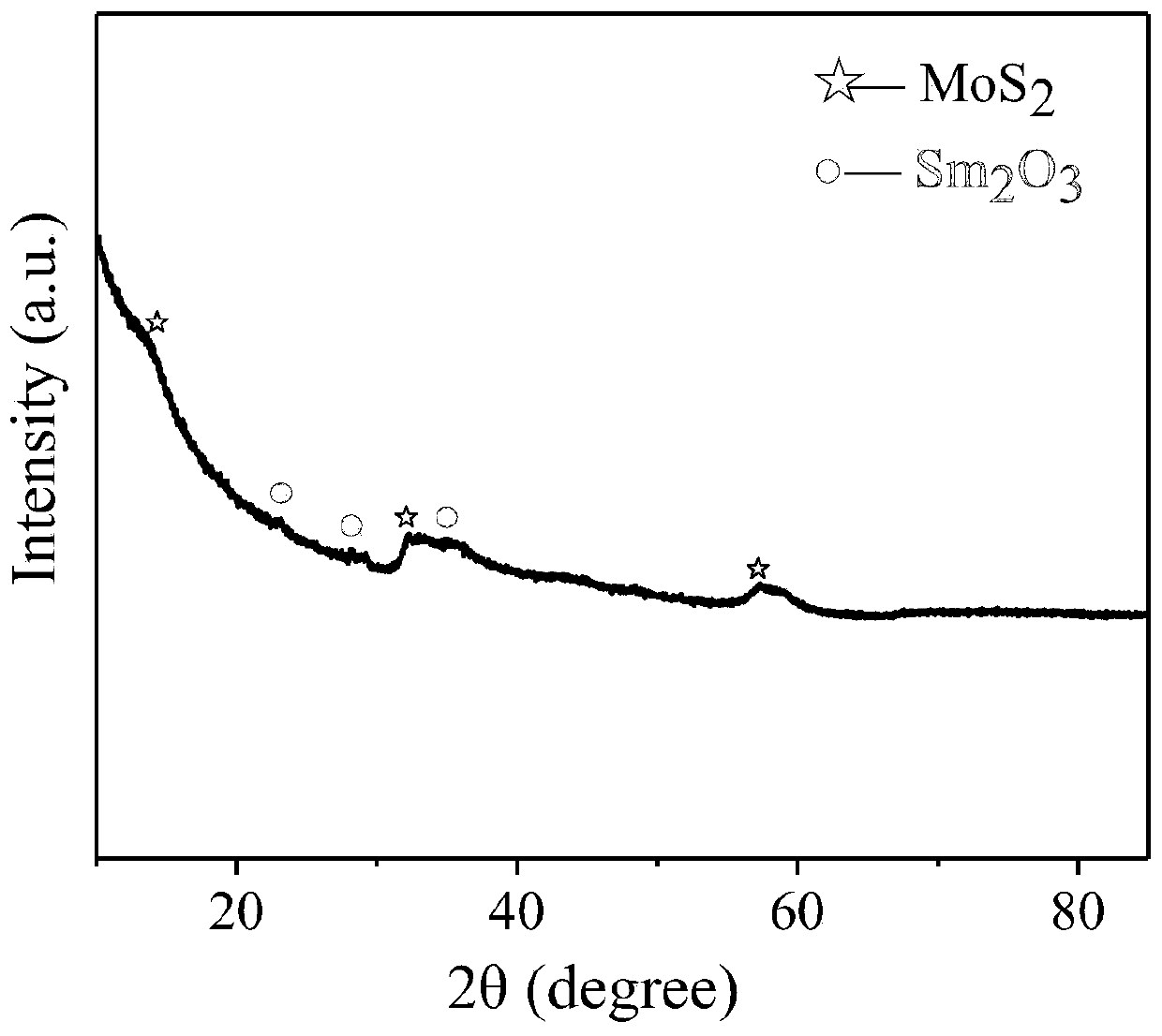

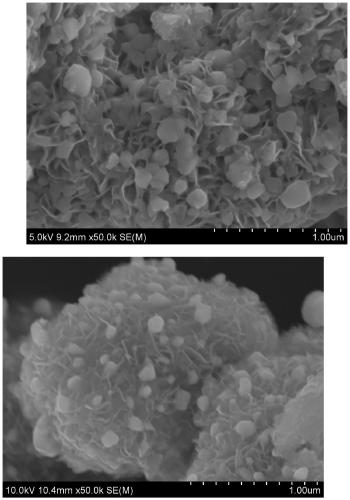

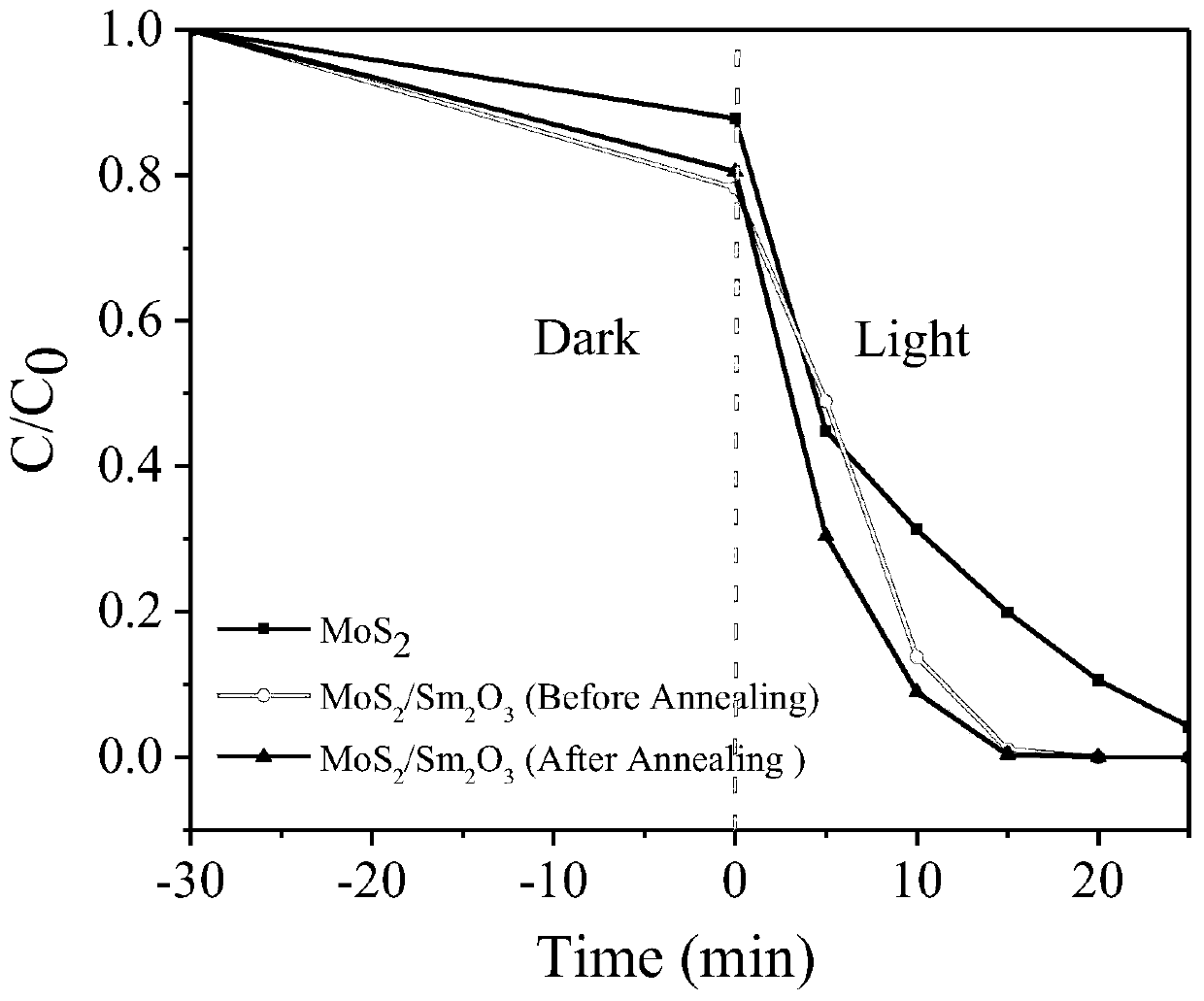

[0028] The invention provides a novel mesoporous MoS for degrading organic pollutants 2 / Sm 2 o 3Photocatalyst and its preparation method. The present invention uses sodium molybdate and thiourea as the main raw materials, citric acid as the acidity regulator, firstly prepares petal-shaped molybdenum disulfide powder by hydrothermal synthesis, and dissolves the obtained molybdenum disulfide powder in samarium nitrate solution for ultrasonication After that, sodium hydroxide solution was added dropwise, filtered, dried, and annealed to obtain photocatalytically active mesoporous MoS 2 / Sm 2 o 3 catalyst of light. A novel mesoporous MoS for degrading organic pollutants of the present invention 2 / Sm 2 o 3 Photocatalysts are composite oxides composed of mesoporous and nanoscale. The catalyst has a complete morphology, samarium oxide is evenly loaded on the surface of molybdenum disulfide, has good crystallinity, and developed mesopores, which can improve its photocatalyt...

Embodiment 1

[0036] Weigh 0.578 g of sodium molybdate and 0.7 g of thiourea, dissolve them in 40 ml of deionized water and stir for 30 minutes until completely dissolved, then add 0.47 g of citric acid, stir for 10 minutes, transfer to a hydrothermal reaction kettle, and heat at 200 degrees After 21 hours of reaction at lower temperature, it was taken out, washed with deionized water, and dried at 60 degrees to obtain molybdenum disulfide powder. Weigh 0.05 g of precursor molybdenum disulfide powder, dissolve 50 ml of 0.0005 mol / L samarium nitrate in it and ultrasonicate for 5 minutes, then add 40 ml of 0.002 mol / L sodium hydroxide solution dropwise at 0°C , at this time the molar ratio of molybdenum disulfide / samarium oxide was 1:0.08, then washed, filtered, dried and annealed in a tube furnace to obtain mesoporous MoS 2 / Sm 2 o 3 Photocatalyst, denoted as 1# sample.

Embodiment 2

[0038] Weigh 0.578 g of sodium molybdate and 0.7 g of thiourea, dissolve them in 40 ml of deionized water and stir for 30 minutes until completely dissolved, then add 0.47 g of citric acid, stir for 10 minutes, transfer to a hydrothermal reaction kettle, and heat at 200 degrees After 21 hours of reaction at lower temperature, it was taken out, washed with deionized water, and dried at 60 degrees to obtain molybdenum disulfide powder. Weigh 0.05 g of precursor molybdenum disulfide powder, dissolve 50 ml of 0.001 mol / L samarium nitrate in it and ultrasonicate for 5 minutes, then add 80 ml of 0.002 mol / L sodium hydroxide solution dropwise at 0°C , at this time the molar ratio of molybdenum disulfide / samarium oxide was 1:0.16, then washed, filtered, dried and annealed in a tube furnace to obtain mesoporous MoS 2 / Sm 2 o 3 Photocatalyst, recorded as 2# sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com