Method for preparing mesoporous nano particle-enhanced nylon composite material

A nylon composite material and nanoparticle technology are applied in the field of preparation of nano-inorganic particle reinforced nylon composite materials to achieve excellent effects, unique mesoporous structure, and ultra-high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

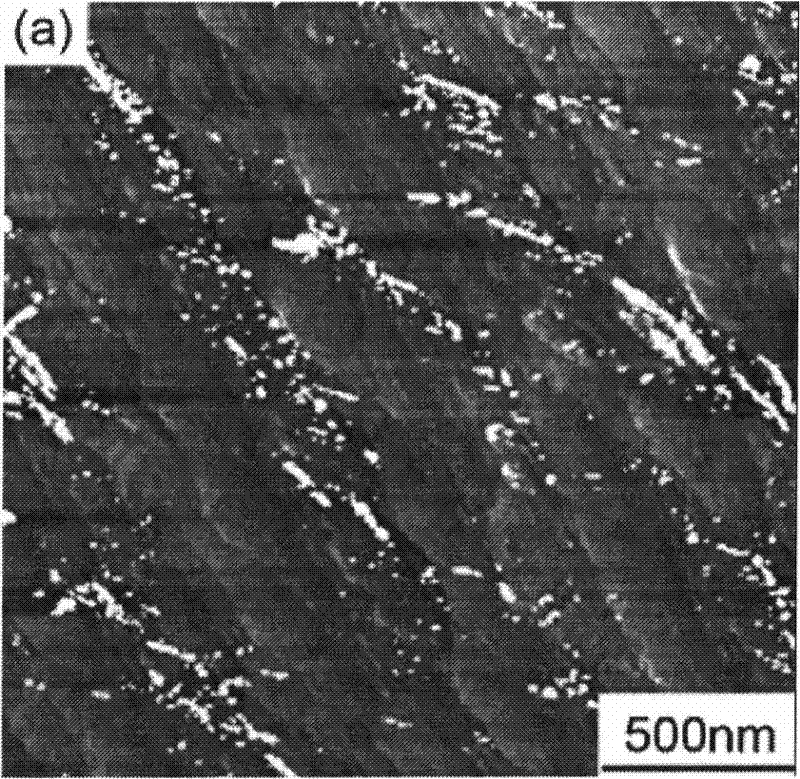

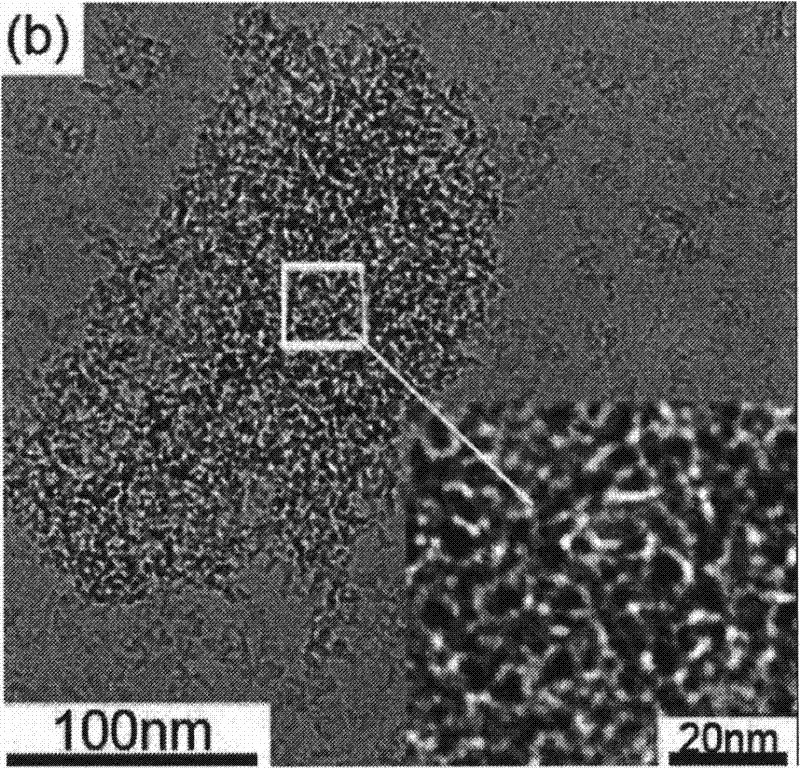

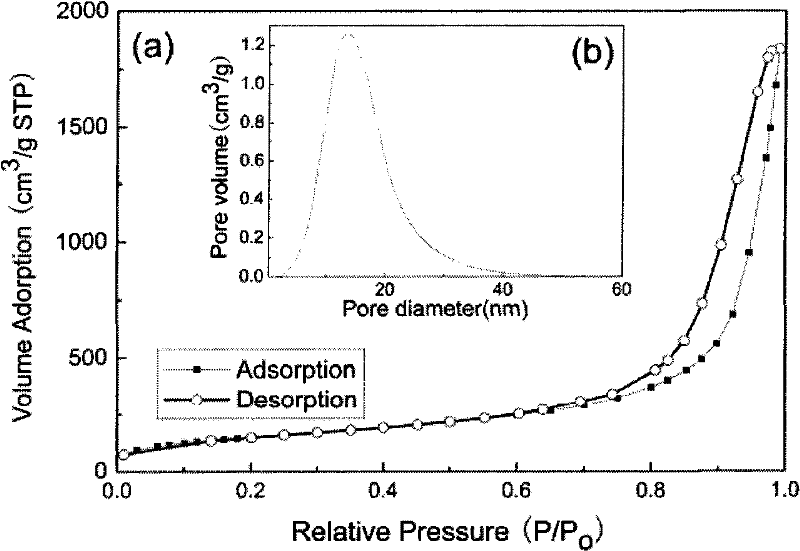

Image

Examples

Embodiment 1

[0020] The inorganic materials involved in the present invention include silicon dioxide, titanium dioxide, etc. In order to better illustrate the present invention, the following is an example in detail with the mesoporous nanometer silicon dioxide / nylon 6 system. The silicon dioxide content of the example product is: 3% wt.

[0021] The first step: hydrolysis of tetraethyl orthosilicate

[0022] Disperse 1 mol of tetraethyl orthosilicate in 1000 ml of water, adjust the pH value of the solution to 3 with phosphoric acid, and react at 80° C. for 2 hours under stirring to form a hydrosol.

[0023] The response is as follows:

[0024] The second step: material mixing

[0025] After mixing 2000 grams of caprolactam and 20 grams of benzoic acid with the hydrosol, they were added to an autoclave. The oxygen in the polymerization tank was evacuated by first vacuuming and then filling with nitrogen. Pre-polymerize under the conditions of 230°C and 2.0MPa for 8 hours, then reduc...

Embodiment 2

[0032] The first step: hydrolysis of tetraethyl titanate

[0033] Disperse 2 mol of tetraethyl orthosilicate in 4500 ml of water, adjust the pH of the solution to 2.1 with phosphoric acid, and react at 45° C. for 4 hours under stirring to form a hydrosol.

[0034] The second step: material mixing

[0035] After mixing 3,000 grams of laurolactam, 36 grams of adipic acid and the hydrosol, they were added to the high-pressure polymerization kettle, and the oxygen in the polymerization kettle was evacuated by first vacuuming and then filling with nitrogen. Pre-polymerize at 270°C and 3.2MPa for 14 hours, then reduce the pressure in the kettle to normal pressure by venting water vapor, control the temperature in the kettle at 235-250°C during the exhaust process, and continue to react at normal pressure for 4 hours , and then perform post-decompression polycondensation to increase the degree of reaction. The temperature of decompression polycondensation is 220°C and the pressure i...

Embodiment 3

[0037] The first step: hydrolysis of aluminate

[0038] Disperse 1 mol of aluminate in 4500 ml of water, use phosphoric acid to adjust the pH value of the solution to 5, and react at 100° C. for 4 hours under stirring to form a hydrosol.

[0039] The second step: material mixing

[0040] After mixing 10,000 grams of nylon 66 salt, 20 grams of adipic acid and the hydrosol, they are added to the high-pressure polymerization kettle, and the oxygen in the polymerization kettle is evacuated by first vacuuming and then filling with nitrogen. Pre-polymerize at 200°C and 0.2MPa for 2 hours, then reduce the pressure in the kettle to normal pressure by venting water vapor, control the temperature in the kettle at 235-250°C during the exhaust process, and continue to react at normal pressure for 1 hour , and then carry out post-decompression polycondensation to increase the degree of reaction. The temperature of decompression polycondensation is 300 ° C, and the pressure is 200 Pa until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com