A kind of antibacterial composite material and mat prepared by the composite material

A composite material and mat technology, applied in applications, bedspreads, household utensils, etc., can solve problems such as easy breeding of mites, bacteria, human health effects, straw mats are not washable, etc., to achieve large specific heat capacity, easy to clean, and not easy to fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

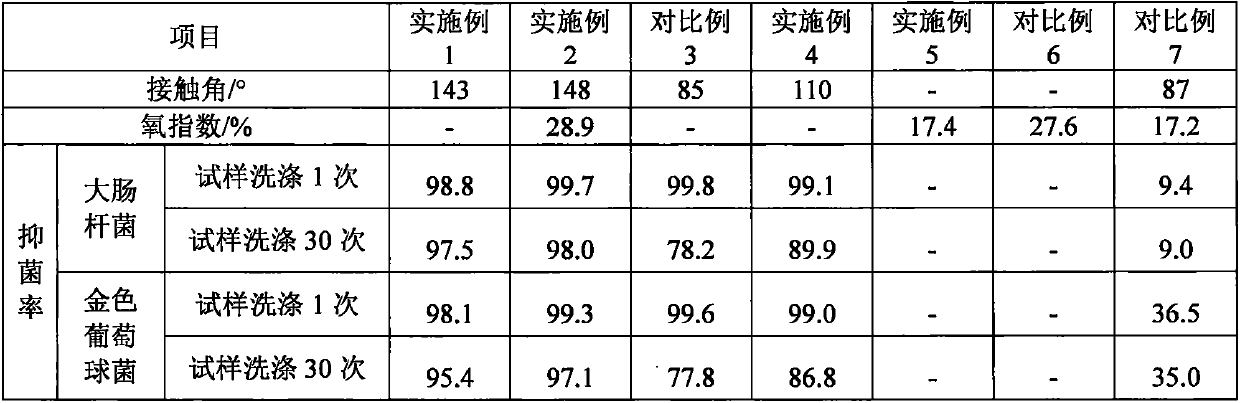

Examples

Embodiment 1

[0029] A polymer-coated nano zinc oxide particle is provided, which is prepared by the following method:

[0030] (1) 20 mass parts of nano-zinc oxide and deionized water are mixed into a water suspension with a mass fraction of 10%, and 0.5 mass parts of polyvinylpyrrolidone are added to the above-mentioned water suspension, stirred under the condition of 1500r / min Disperse for 80 minutes, and adjust the pH value of the uniformly dispersed suspension to 6.5;

[0031] (2) Stir and heat the suspension obtained in step (1) to 78° C. under the condition of 450 r / min, and add 0.4 parts by mass of ammonium persulfate after stabilizing for 12 minutes;

[0032] (3) Add 20 mass parts of divinylbenzene to the suspension obtained in step (2), after reacting for 1 hour, add dropwise the 1-vinyl-3-alkylimidazolium iodide ionic liquid of 10 mass parts, continue After reacting for 3 hours, stop the reaction;

[0033] (4) Cool the reaction solution obtained in step (3) to room temperature ...

Embodiment 2

[0037] A polymer-coated nano zinc oxide particle is provided, which is prepared by the following method:

[0038] (1) 20 mass parts of nano-zinc oxide and deionized water are mixed into a water suspension with a mass fraction of 10%, and 0.5 mass parts of polyvinylpyrrolidone are added to the above-mentioned water suspension, stirred under the condition of 1500r / min Disperse for 80 minutes, and adjust the pH value of the uniformly dispersed suspension to 6.5;

[0039] (2) Stir and heat the suspension obtained in step (1) to 78° C. under the condition of 450 r / min, and add 0.4 parts by mass of ammonium persulfate after stabilizing for 12 minutes;

[0040] (3) Add 20 mass parts of divinylbenzene to the suspension obtained in step (2), after reacting for 1 hour, drop 10 mass parts of 1-vinylimidazole, continue to react after 3 hours, stop the reaction;

[0041] (4) Cool the reaction solution obtained in step (3) to room temperature and then vacuum filter, place the filter cake i...

Embodiment 4

[0047] A polymer-coated nano zinc oxide particle is provided, which is prepared by the following method:

[0048] (1) 20 mass parts of nano-zinc oxide and deionized water are mixed into a water suspension with a mass fraction of 10%, and 0.5 mass parts of polyvinylpyrrolidone are added to the above-mentioned water suspension, stirred under the condition of 1500r / min Disperse for 80 minutes, and adjust the pH value of the uniformly dispersed suspension to 6.5;

[0049](2) Stir and heat the suspension obtained in step (1) to 78° C. under the condition of 450 r / min, and add 0.4 parts by mass of ammonium persulfate after stabilizing for 12 minutes;

[0050] (3) Add 20 parts by mass of divinylbenzene to the suspension obtained in step (2), after reacting for 3 hours, stop the reaction;

[0051] (4) Cool the reaction solution obtained in step (3) to room temperature and then vacuum filter, place the filter cake in a drying oven at 70°C for 30 hours, and pulverize the dried filter c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com