Preparation method of two-phase low-temperature co-sintered temperature stable dielectric ceramic material

A temperature-stable, ceramic material technology is applied in the field of preparation of barium titanate-bismuth sodium titanate two-phase low-temperature co-fired dielectric temperature-stable dielectric ceramics, and can solve problems such as increased loss, adverse effects on device performance, and the like, Achieving the effect of large dielectric constant, improved dielectric temperature stability and good dielectric temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

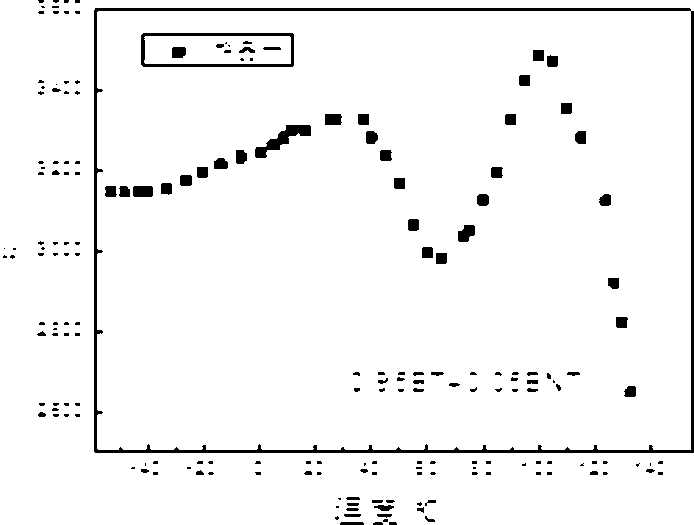

Embodiment 1

[0024] 1. Take BaCO 3 and TiO 2 0.2 mol each, mixed ball milling, the ball milling medium is water and zirconia balls, the ball milling speed is 100 r / min, and the time is 4 hours.

[0025] 2. Put the slurry at 100 o Dry at C, grind, put the powder in a crucible and place it in a muffle furnace for calcination, the calcination temperature is 1250 o C, close to the sintering temperature of pure BT body, the calcination time is 4 hours.

[0026] 3. Grind the shrinkage and agglomerated billets to obtain BT billets (powder).

[0027] 4. Take Na 2 CO 3 、 Bi 2 o 3 0.05mol each, TiO 2 Take 0.2 mol, mix and ball mill, the ball milling medium is ethanol and zirconia balls, the ball milling speed is 100r / min, and the ball milling time is 4 hours.

[0028] 5. Put the slurry at 100 o Dry at C, grind, put the powder in a crucible and place it in a muffle furnace for calcination, the calcination temperature is 800 o C, lower than the sintering temperature of the BNT green body, a...

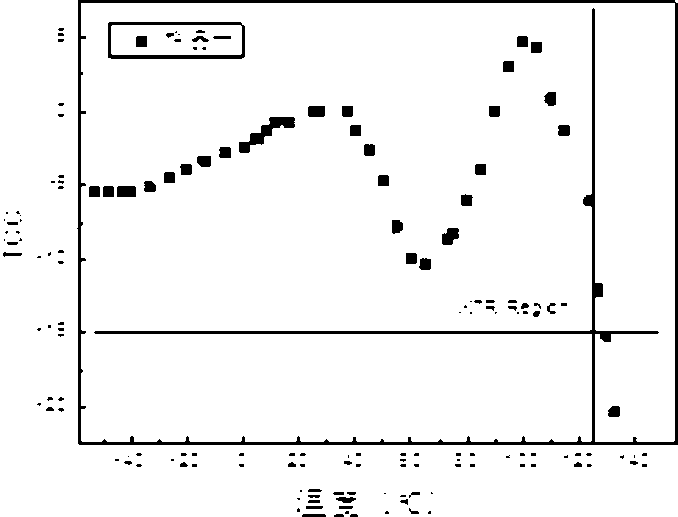

Embodiment 2

[0035] 1. Take BaCO 3 and TiO 2 0.2 mol each, mixed ball milling, the ball milling medium is water and zirconia balls, the ball milling speed is 100 r / min, and the time is 4 hours.

[0036] 2. Put the slurry at 100 o Dry at C, grind, put the powder in a crucible and place it in a muffle furnace for calcination, the calcination temperature is 1250 o C, close to the sintering temperature of pure BT body, the calcination time is 4 hours.

[0037] 3. Grind the shrinkage and agglomerated billets to obtain BT billets (powder).

[0038] 4. Take Na 2 CO 3 、 Bi 2 o 3 0.05mol each, TiO 2 Take 0.2 mol, mix and ball mill, the ball milling medium is ethanol and zirconia balls, the ball milling speed is 100r / min, and the ball milling time is 4 hours.

[0039] 5. Put the slurry at 100 o Dry at C, grind, put the powder in a crucible and place it in a muffle furnace for calcination, the calcination temperature is 800 o C, lower than the sintering temperature of the BNT green body, a...

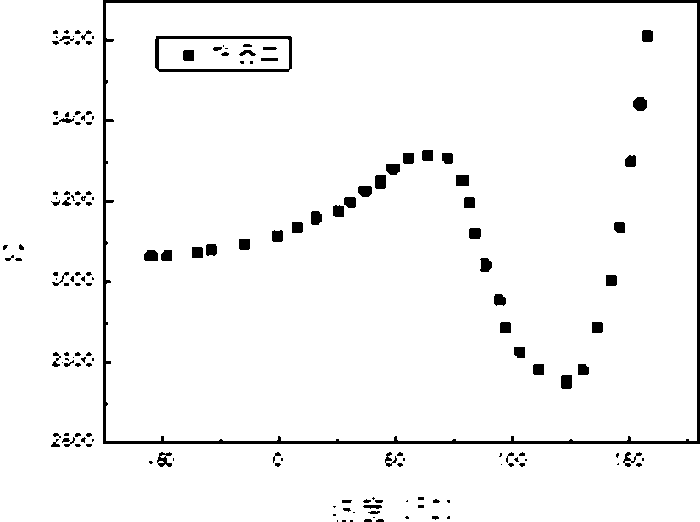

Embodiment 3

[0048] 1. Take BaCO 3 and TiO 2 0.2 mol each, mixed ball milling, the ball milling medium is water and zirconia balls, the ball milling speed is 100 r / min, and the time is 4 hours.

[0049] 2. Put the slurry at 100 o Dry at C, grind, put the powder in a crucible and place it in a muffle furnace for calcination, the calcination temperature is 1250 o C, close to the sintering temperature of pure BT body, the calcination time is 4 hours.

[0050] 3. Grind the shrinkage and agglomerated billets to obtain BT billets (powder).

[0051] 4. Take Na 2 CO 3 、 Bi 2 o 3 0.05mol each, TiO 2 Take 0.2 mol, mix and ball mill, the ball milling medium is ethanol and zirconia balls, the ball milling speed is 100r / min, and the ball milling time is 4 hours.

[0052] 5. Put the slurry at 100 o Dry at C, grind, put the powder in the crucible and calcined in the muffle furnace, the calcining temperature is 800 o C, the lower the sintering temperature of the BNT green body, the higher the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com