Bismuth titanate catalyst with sunlight photocatalytic activity

A photocatalytic activity and photocatalyst technology, applied in the field of photocatalysis, can solve problems such as reducing the band gap energy, and achieve the effects of cheap raw materials, easy availability of raw materials, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] (1) Bismuth titanate (Bi 4 Ti 3 o 12 )Synthesis

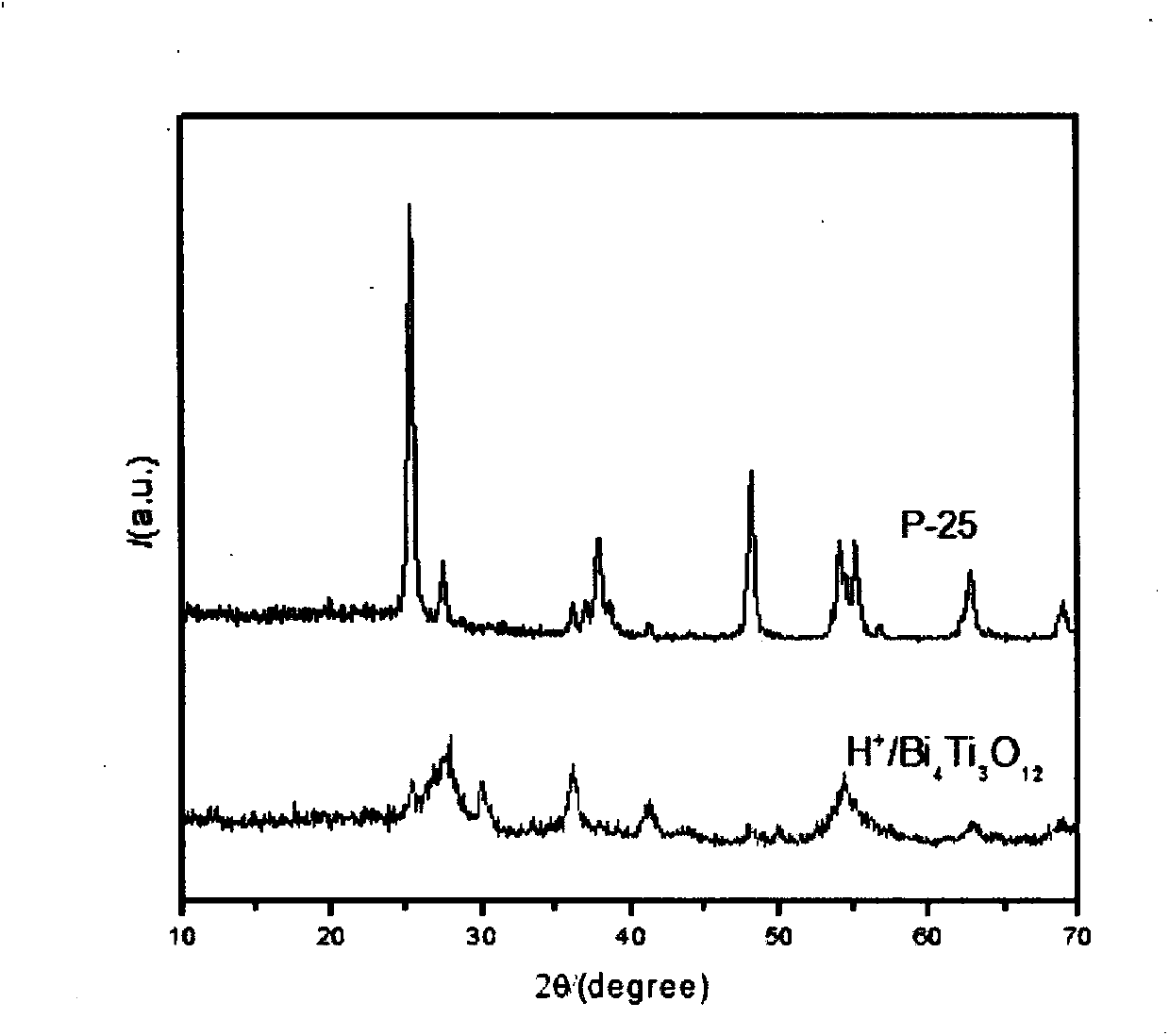

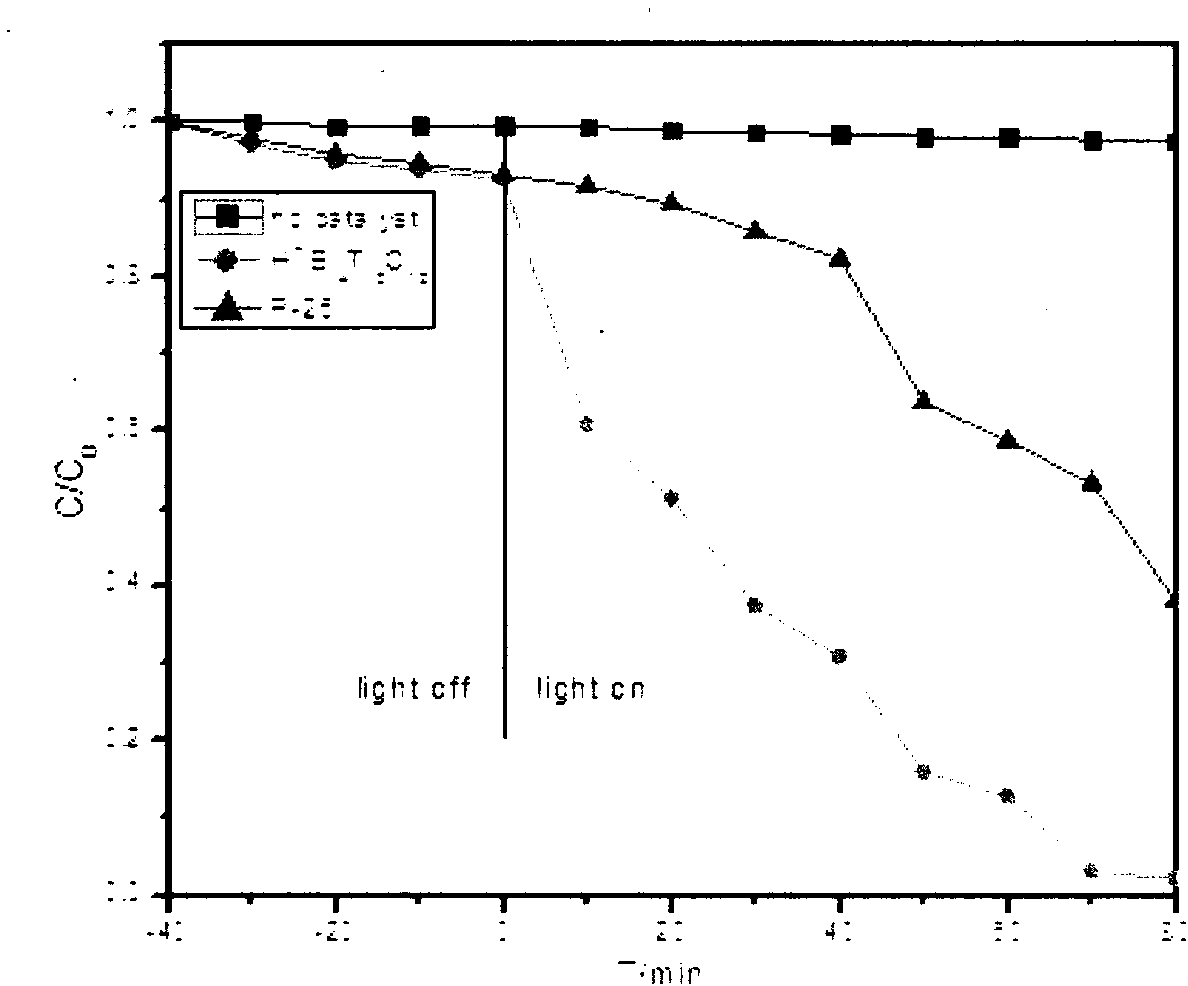

[0012] 0.97g of Bi(NO 3 ) 3 ·5H 2 O is uniformly dispersed in 0.5mol / L nitric acid solution, and 0.0015mol of P25 is added thereto, stirred until uniformly dispersed, adjusted to pH 9-12 with 0.2mol / L caustic soda solution, left standing, suction filtered, and Calcined at 600 °C for 1 h in a muffle furnace to obtain a light yellow solid Bi 4 Ti 3 o 12 ; Product XRD see attached figure 1 , compared with the orthosymmetric Aurivillius 4 Ti 3 o 12 (card JCPDS35-0795) match. Measure its acid content as 0.08mmol / L, measure its specific surface area as 8.8694m 2 / g.

[0013] (2) Preparation of acid bismuth titanate photocatalyst

[0014] Weigh 1g Bi 4 Ti 3 o 12 , add it to 20ml of concentrated nitric acid, stir at a constant temperature of 60°C for 40min, let it stand and pour off the supernatant, wash the precipitate with deionized water until neutral, filter it with suction, and dry it at a constant temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com