Preparation method of two-dimensional carbon nitride/two-dimensional titanium dioxide composite material

A technology of titanium dioxide and composite materials, which is applied in the field of nanomaterials and photocatalysis, can solve the problems of small interfacial contact area of composite materials, low light utilization rate of titanium dioxide, and high recombination rate of photogenerated carriers, so as to improve photocatalytic activity, close contact, The effect of shortening the transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Mix and grind 4 grams of melamine and 10 grams of ammonium chloride evenly, transfer to a crucible, raise the temperature to 550°C in a muffle furnace at a rate of 2°C / min, and anneal for 2 hours to obtain yellow carbon nitride nanosheets .

[0023] Step 2: Add 200 mg of the above-mentioned carbon nitride into 31.5 ml of isopropanol, and ultrasonically disperse for 30 min. Then add 0.025 mL of diethylenetriamine (EDTA) into it, stir for 10 min, continue to add 1.125 mL of diisopropyl di(acetylacetonate) titanate, and stir for 10 min. The resulting solution was transferred into a reaction kettle, and subjected to solvent heat treatment at 200° C. for 24 hours. After the reaction, cool to room temperature, wash the precipitate three times with deionized water and absolute ethanol, place in an oven at 60°C, and dry for 24 hours to obtain a two-dimensional carbon nitride / two-dimensional titanium dioxide nanocomposite material.

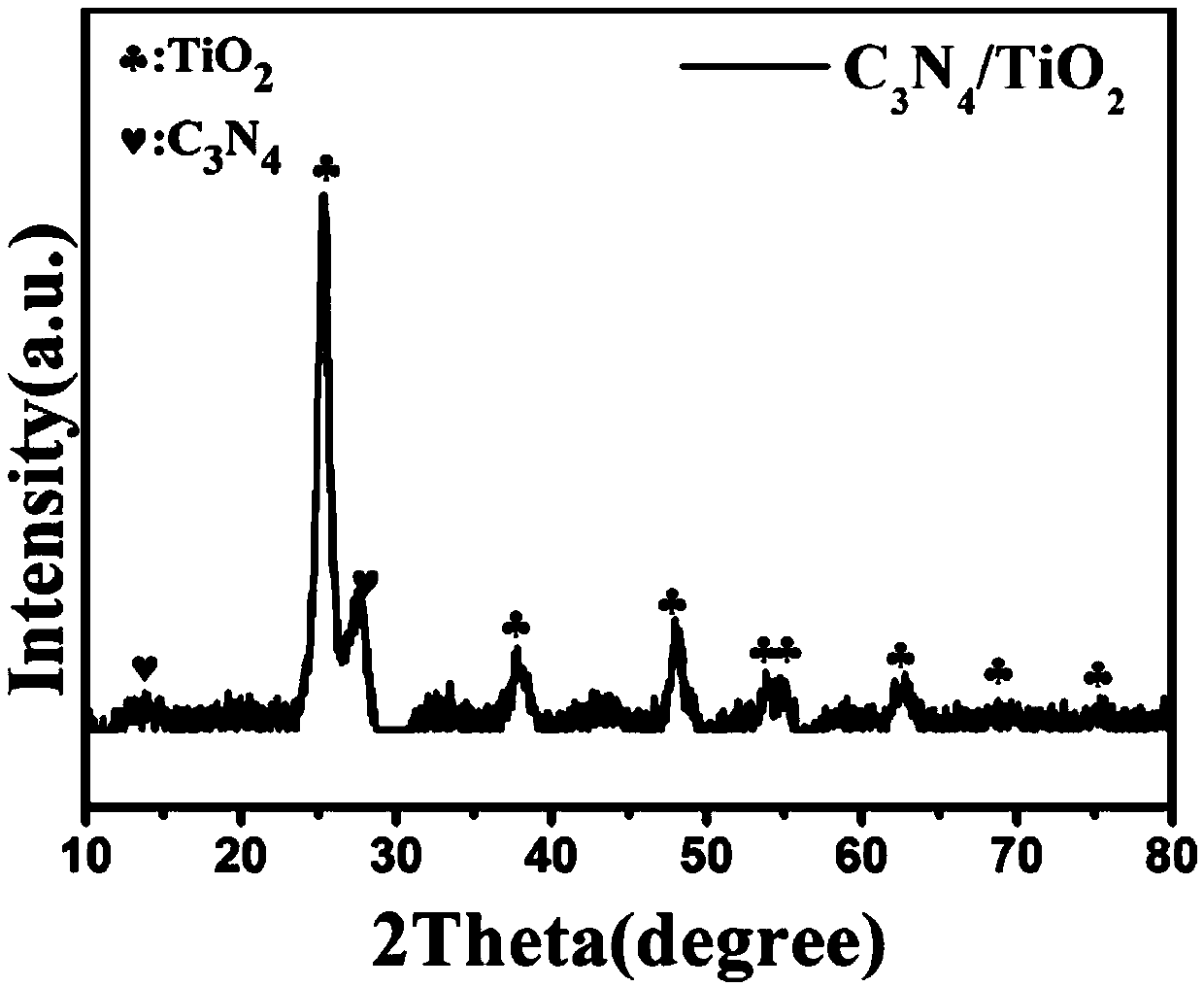

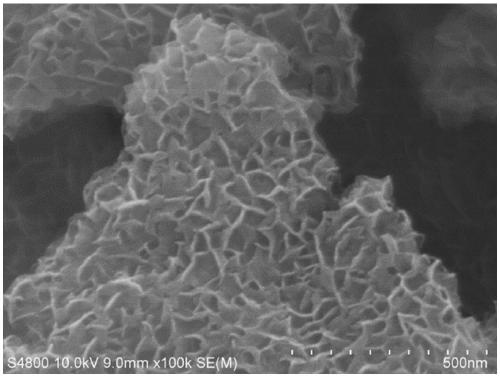

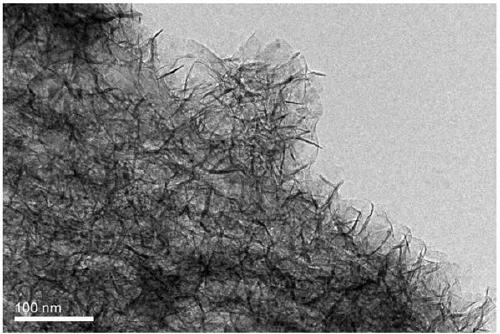

[0024] figure 1 It is the XRD patt...

Embodiment 2

[0029] Step 1: Mix and grind 1 gram of melamine and 2 grams of ammonium chloride evenly, transfer to a crucible, raise the temperature in a muffle furnace to 500°C at a rate of 1°C / min, and anneal for 2 hours to obtain yellow carbon nitride nanosheets .

[0030] Step 2: Add 100 mg of the above-mentioned carbon nitride into 30 ml of isopropanol, and ultrasonically disperse for 30 min. Then add 0.02 mL of diethylenetriamine (EDTA) into it, stir for 10 min, continue to add 1.0 mL of diisopropyl di(acetylacetonate) titanate, and stir for 10 min. The resulting solution was transferred into a reaction kettle, and subjected to solvent heat treatment at 180° C. for 20 hours. After the reaction, cool to room temperature, wash the precipitate three times with deionized water and absolute ethanol, place in an oven at 60°C, and dry for 24 hours to obtain a two-dimensional carbon nitride / two-dimensional titanium dioxide nanocomposite material.

[0031] According to the method described i...

Embodiment 3

[0033] Step 1: Mix and grind 10 grams of melamine and 25 grams of ammonium chloride evenly, transfer them to a crucible, raise the temperature to 600 degrees Celsius at a rate of 10 degrees Celsius / min in a muffle furnace, and anneal for 4 hours to obtain yellow carbon nitride nanosheets .

[0034]Step 2: Take 800 mg of the above-mentioned carbon nitride and add it to 35 ml of isopropanol, and ultrasonically disperse for 30 min. Then add 0.05 mL of diethylenetriamine (EDTA) into it, stir for 10 min, continue to add 1.5 mL of diisopropyl di(acetylacetonate) titanate, and stir for 10 min. The resulting solution was transferred into a reaction kettle, and subjected to solvent heat treatment at 220° C. for 30 hours. After the reaction, cool to room temperature, wash the precipitate three times with deionized water and absolute ethanol, place in an oven at 60°C, and dry for 24 hours to obtain a two-dimensional carbon nitride / two-dimensional titanium dioxide nanocomposite material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com