Photocatalyst and preparation method and application thereof

A photocatalyst and catalyst technology, applied in the field of photocatalysis, can solve the problems of slow photoelectron-hole separation, limited photocatalytic performance of semiconductor materials, easy recombination of photogenerated carriers, and achieve low cost, good visible light absorption performance, The effect of simple preparation method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

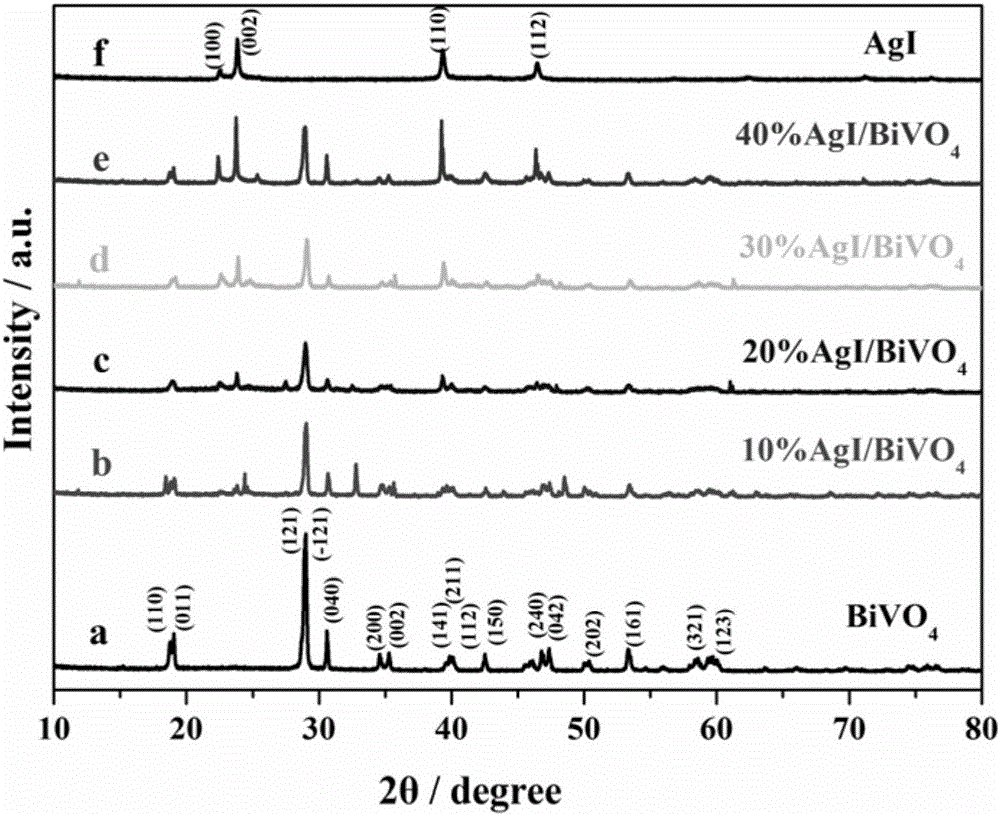

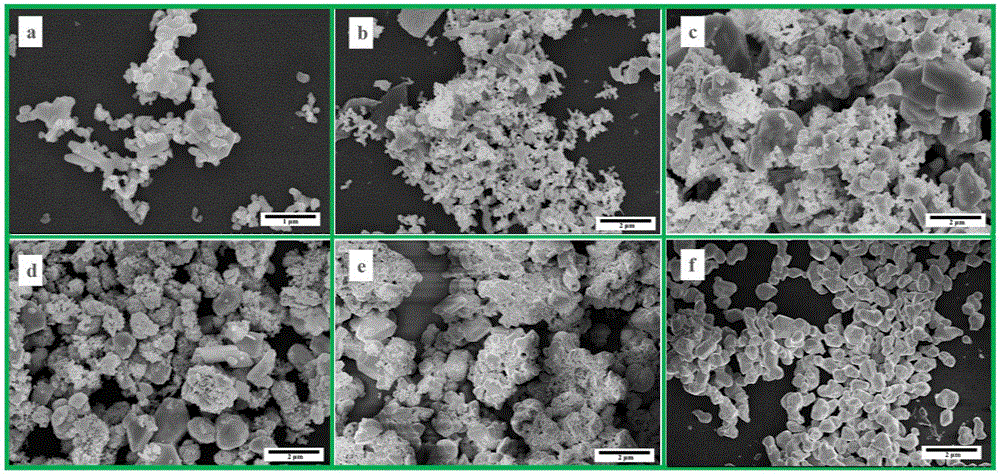

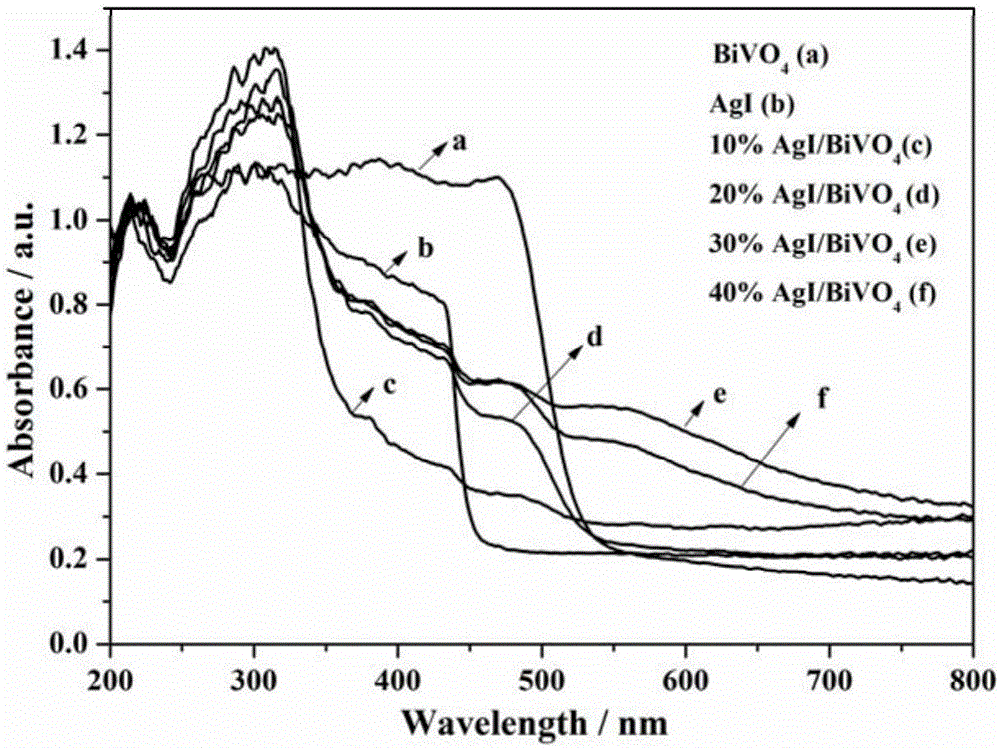

[0039] 0.002mol of KI and 0.008mol of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 40 mL of deionized water, and stirred for 30 min to obtain solution A. At the same time, 0.002moL of AgNO 3 and 0.008mol NH 4 VO 3 Dissolve in 40mL deionized water and stir for 30min to obtain solution B. Solution A was added dropwise to solution B with stirring. The above suspension was transferred to a 100mL reaction kettle after being stirred for 60min, and heated in water at 180°C for 24h. After cooling to room temperature, suction filter on a microporous membrane with a pore size of 0.45 μm, wash the product several times with ultrapure water and absolute ethanol, and place it in a vacuum drying oven at 60°C for 6 hours to obtain a sample marked as 20% AgI / BiVO 4 .

Embodiment 2

[0047] AgI / BiVO 4 Preparation method of heterojunction composite photocatalyst:

[0048] Prepared by co-precipitation and hydrothermal method, the difference from Example 1 is that the control of AgI and BiVO 4 The molar ratio of 1:9. 0.001mol of KI and 0.009mol of NH 4 VO 3 Dissolve in 40mL deionized water and stir for 30min to obtain solution A. At the same time, 0.001mol AgVO 3 and 0.009mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 40 mL deionized aqueous solution, and stirred for 30 min to obtain solution B. Solution A was then added dropwise to solution B with stirring. The above suspension was transferred to a 100mL reaction kettle after being stirred for 60min, and heated in water at 180°C for 24h. After cooling to room temperature, suction filter on a microporous membrane with a pore size of 0.45 μm, wash the product several times with ultrapure water and absolute ethanol, and place it in a vacuum drying oven at 60°C for 6 hours to obtain a sample marked as 10% Ag...

Embodiment 3

[0050] AgI / BiVO 4 Preparation method of heterojunction composite photocatalyst:

[0051] Prepared by co-precipitation and hydrothermal method, the difference from Example 1 is that the control of AgI and BiVO 4 The molar ratio is 3:7. 0.003mol of KI and 0.007mol of NH 4 VO 3 Dissolve in 40mL deionized water and stir for 30min to obtain solution A. At the same time, 0.003mol AgVO 3 and 0.007moL of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 40 mL of deionized water, and stirred for 30 min to obtain solution B. Solution A was then added dropwise to solution B with stirring. The above suspension was transferred to a 100mL reaction kettle after being stirred for 60min, and heated in water at 180°C for 24h. After cooling to room temperature, suction filter on a microporous membrane with a pore size of 0.45 μm, wash the product several times with ultrapure water and absolute ethanol, and place it in a vacuum drying oven at 60°C for 6 hours to obtain a sample marked as 30% AgI / BiV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com