Solvent-thermal method for preparing single-phase bismuth titanate Bi2Ti2O7

A single-phase bismuth titanate, solvothermal technology, applied in chemical instruments and methods, titanium compounds, physical/chemical process catalysts, etc. The problem of high preparation cost of bismuth can achieve the effect of excellent solar photocatalytic activity, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of single-phase bismuth titanate Bi by solvothermal method 2 Ti 2 o 7 method, wherein the molar ratio of bismuth nitrate and tetrabutyl titanate is 0.4:1; the volume ratio of tetrabutyl titanate, glycerol, ethanol and ether is 1: 4.7: 11.7: 3.2.

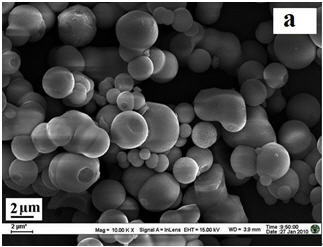

[0037] The specific preparation process is: mix a certain amount of glycerol and ethanol, stir and mix completely, add a certain amount of bismuth nitrate solid and dissolve it completely, slowly add tetrabutyl titanate into the mixed solution, and stir vigorously After 20 minutes, add a certain amount of ether, then stir the mixed solution evenly and transfer it to a 100mL polytetrafluoroethylene-lined reactor; place the closed reactor in a constant temperature oven at 110°C for 12 hours; The mixture in the kettle was filtered and dried, and the solid was placed in a temperature-programmed furnace, and the temperature was raised to 500°C at a rate of 2°C / min for calcination for 3 hours. After cooling, the calcin...

Embodiment 2

[0040] Preparation of single-phase bismuth titanate Bi by solvothermal method 2 Ti 2 o 7 method, wherein the molar ratio of bismuth nitrate and tetrabutyl titanate is 0.4:1; the volume ratio of tetrabutyl titanate, glycerol, ethylene glycol and ether is 1: 4.7: 11.7: 3.2.

[0041] The specific preparation process is as follows: mix a certain amount of glycerol and ethylene glycol, stir and mix completely, add a certain amount of bismuth nitrate solid and dissolve it completely, slowly add tetrabutyl titanate into the mixed solution, After stirring vigorously for 20 minutes, add a certain amount of ether, then stir the mixed solution evenly and transfer it to a 100mL polytetrafluoroethylene-lined reactor; place the closed reactor in a constant temperature oven at 110°C for 12 hours; after cooling The mixture in the reactor was filtered and dried, and the solid was placed in a temperature-programmed furnace, and the temperature was raised to 500°C at a rate of 6°C / min for calc...

Embodiment 3

[0044] Prepare single-phase bismuth titanate Bi according to the method substantially identical with embodiment 1 2 Ti 2 o 7 , The difference from Example 1 is: the reaction kettle was placed in a constant temperature oven at 110° C. for 24 hours, and the rest were the same as in Example 1.

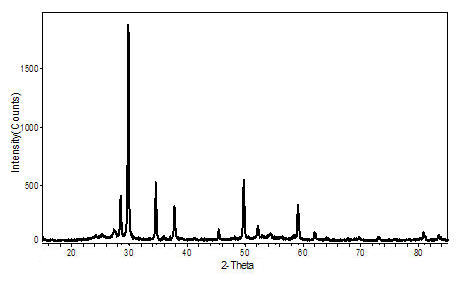

[0045] The X-ray diffraction pattern can confirm that the sample is a single-phase Bi 2 Ti 2 o 7 , the particle size of the sample is about 10nm, and the BET specific surface area is 15.6 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com