TiO2 photocatalyst with mesoporous structure, as well as preparation method and applications of photocatalyst

A photocatalyst and mesoporous structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of unfriendly environment and high price, and achieve easy structure control, convenient operation and high preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 5mL of titanium trichloride solution (1.2mol / L) and add it to a 50mL beaker, then add 0.54g of F127, stir vigorously on a magnetic stirrer for 0.5h until the mixture is uniform, and obtain solution A; spread solution A on a 15cm diameter petri dish, heat-cured at 40°C in a vacuum oven for 96 hours at low temperature; the obtained material was calcined at 500°C to remove non-ionic surfactants and crystallize titanium oxide to obtain TiO 2 sample.

[0022] Structure Characterization

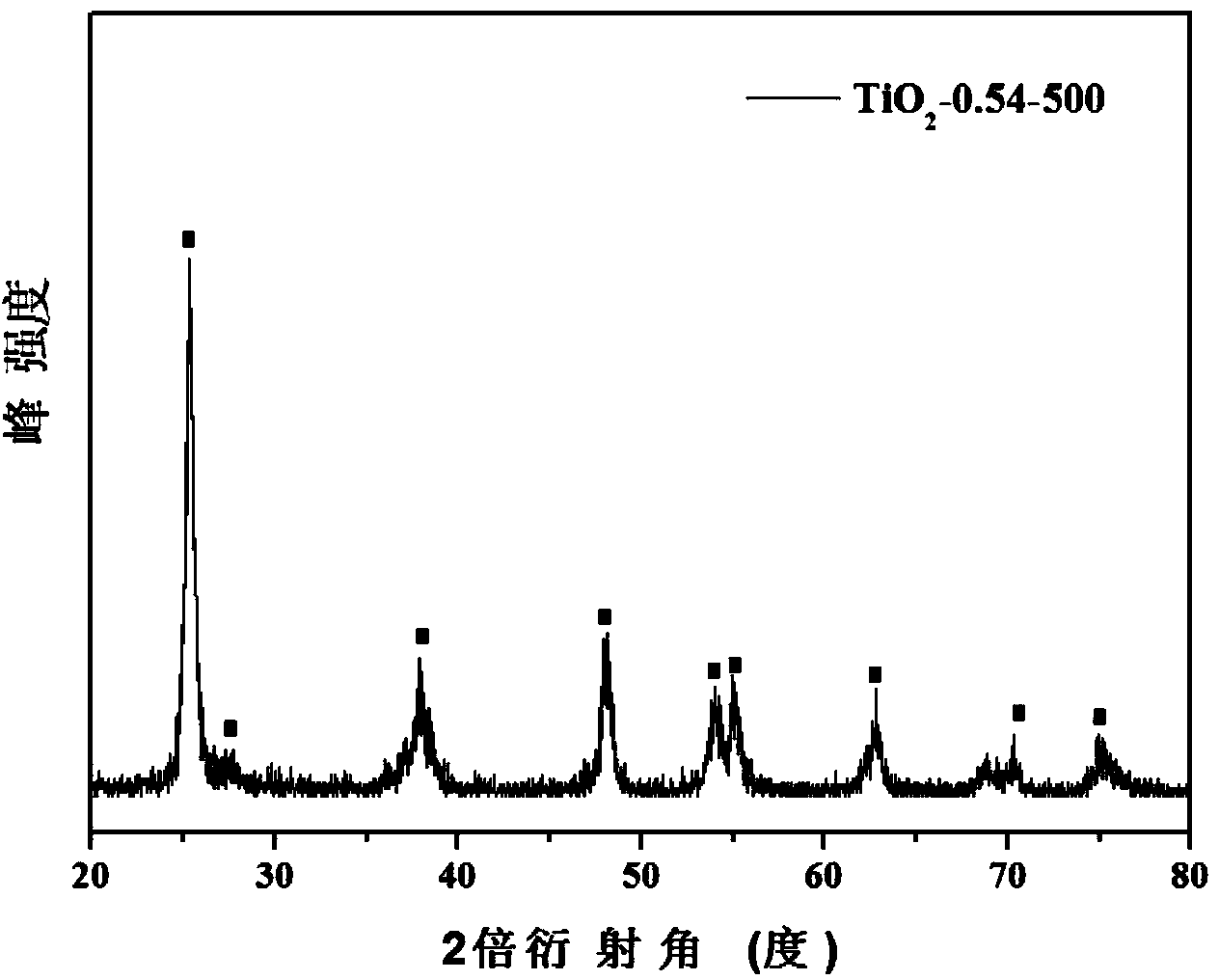

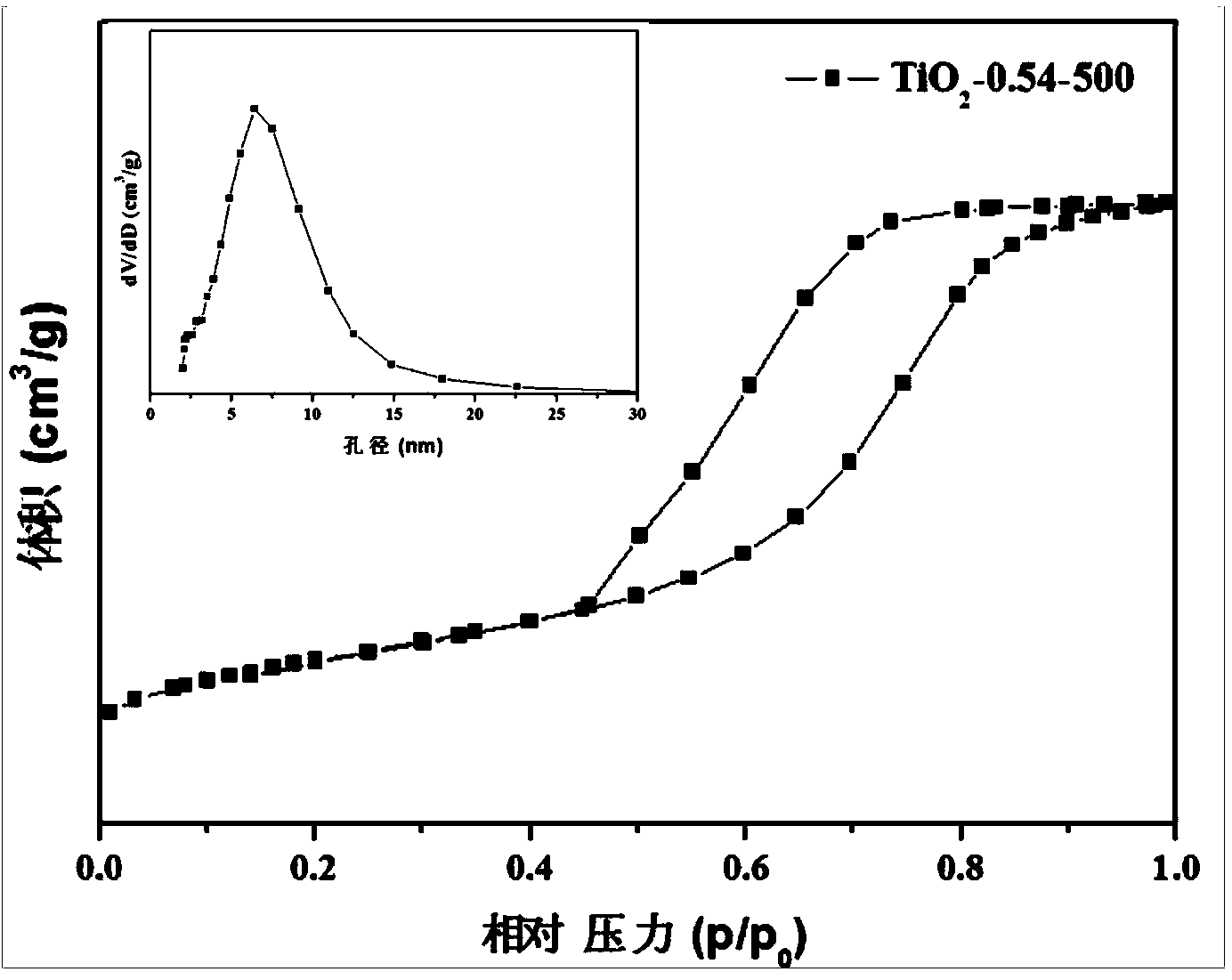

[0023] figure 1 The structural analysis of the sample was carried out by X-ray diffraction measured on a Rigaku D2000 X-ray diffractometer in Japan. It can be seen from the XRD spectrum that the obtained sample is anatase / rutile TiO 2 Out of phase knot; figure 2 Quanta Chrome Nova4000e automatic physical adsorption instrument was used to measure the specific surface area and pore structure of the sample. According to BJH calculation, the specific surface area of the sample was 71....

Embodiment 2

[0027] Take 5 mL of titanyl sulfate solution (volume fraction of titanyl sulfate is 15%) and add it to a 50 mL beaker, then add 0.54 g of F127, stir vigorously on a magnetic stirrer for 0.5 h until uniform, and obtain solution A; spread solution A for one layer on a petri dish with a diameter of 15 cm, and heat-cured in a vacuum oven at 40 °C for 96 h at low temperature; the obtained material was calcined at 500 °C to remove non-ionic surfactants and crystallize titanium oxide to obtain TiO 2 sample.

Embodiment 3

[0029] Take 5mL of tetrabutyl titanate solution (15% tetrabutyl titanate volume fraction) into a 50mL beaker, then add 0.54g of F127, stir vigorously on a magnetic stirrer for 0.5h until uniform, and obtain solution A; A spread a layer on a petri dish with a diameter of 15 cm, and heat-cure it in a vacuum oven at 40 °C for 96 hours at a low temperature; the obtained material is calcined at 500 °C to remove non-ionic surfactants and crystallize titanium oxide to obtain TiO 2 sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com