Petrochemical water-based high-temperature-resistant, anticorrosive and abrasion-resistant coating and method for preparing same

An anti-corrosion, wear-resistant, high-temperature-resistant technology, applied in the field of coatings, can solve the problems of low solid content, no discovery, and high cost, and achieve the effects of excellent chain segment flexibility, improved high-temperature resistance, and easy-to-control structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

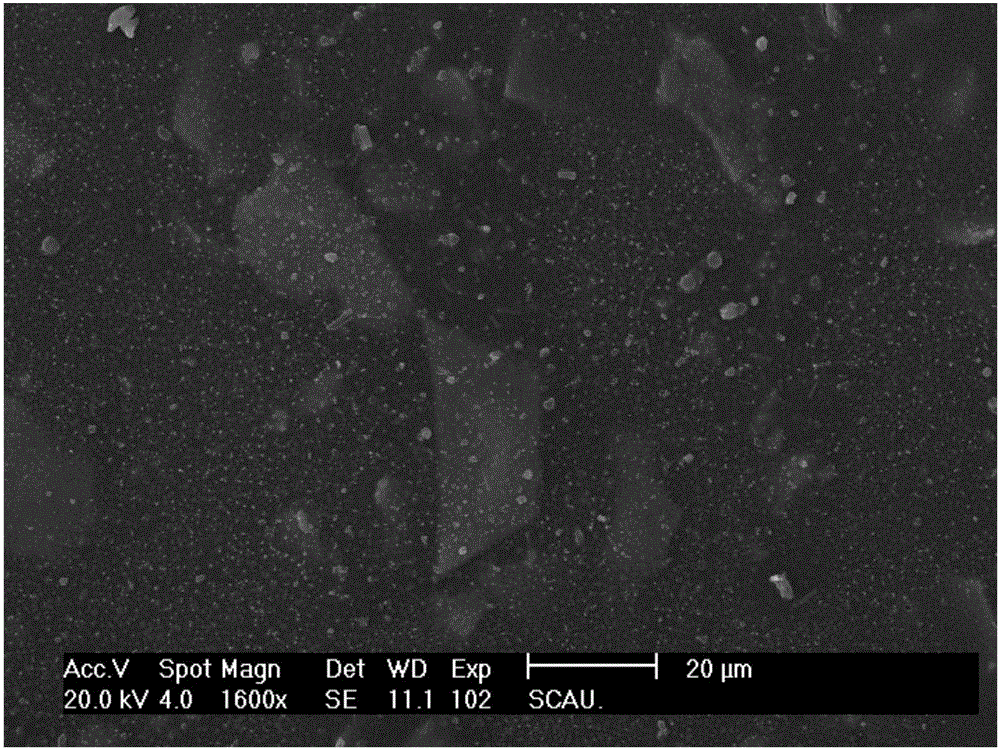

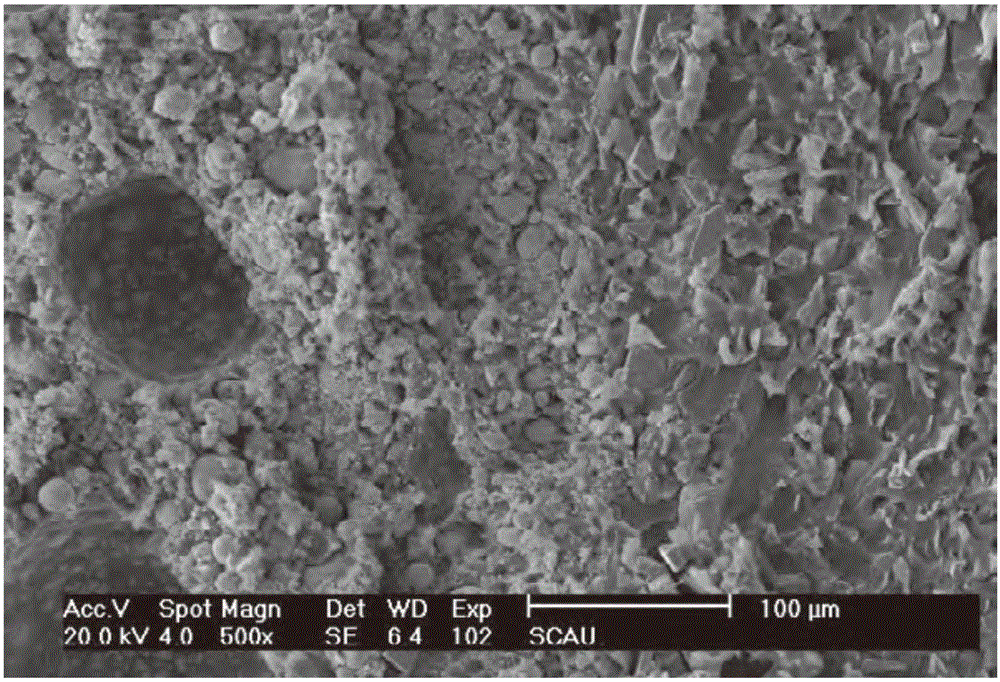

Image

Examples

Embodiment 1

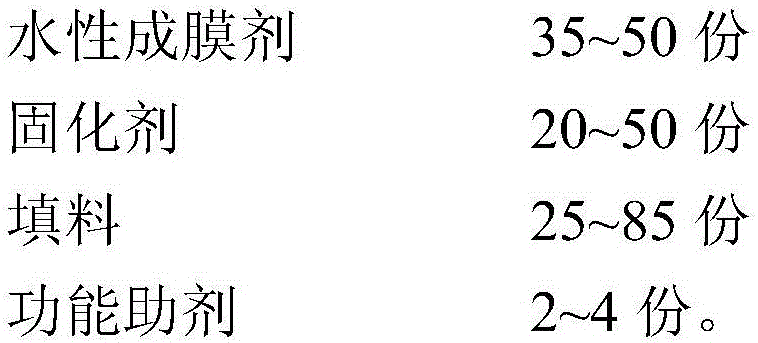

[0064] A water-based high-temperature-resistant anti-corrosion and wear-resistant coating for the petrochemical industry, the composition of each component is shown in Table 1, Table 2, and Table 3:

[0065] Table 1 Waterborne zinc-rich primer formula

[0066]

[0067] Table 2 Waterborne Mica Iron Oxide Intermediate Paint Formula

[0068]

[0069] Table 3 water-based nano wear-resistant topcoat formula

[0070]

[0071]

[0072] The preparation and application method of the above-mentioned water-based high-temperature-resistant anti-corrosion and wear-resistant coating are as follows:

[0073] (1) Water-soluble epoxy resin (TPU 2060, Guangzhou Tangpu Building Decoration Materials Co., Ltd.), zinc powder (500 mesh), phosphorus iron powder (500 mesh), defoamer (N-SiCO-2080 type, Guangzhou Touareg Trading Co., Ltd.), leveling agent (N-SiCO-3038 type, Guangzhou Touareg Trading Co., Ltd.) and dispersant (BYK-A 530, BYK Chemicals) were added and mixed according to the ...

Embodiment 2

[0087] A water-based high temperature resistant anti-corrosion and wear-resistant coating, the composition of each component is shown in Table 6, Table 7, and Table 8:

[0088] Formulation of table 6 water-based zinc-rich primer

[0089]

[0090]

[0091] Table 7 Waterborne Mica Iron Oxide Intermediate Paint Formula

[0092]

[0093] Table 8 water-based nano wear-resistant topcoat formula

[0094]

[0095] The preparation and application method of the above-mentioned water-based high-temperature-resistant anti-corrosion and wear-resistant coating are as follows:

[0096] (1) Water-soluble silicone modified epoxy resin (self-made), zinc powder (500 mesh), phosphorus iron powder (500 mesh), defoamer (N-SiCO-2080 type, Guangzhou Touareg Trading Co., Ltd.), Leveling agent (N-SiCO-3038 type, Guangzhou Touareg Trading Co., Ltd.) and dispersant (BYK-A 530, BYK Chemicals) were added and mixed according to the formula, and the water-based rich Zinc primer mixture.

[0097...

Embodiment 3

[0108] A water-based high-temperature-resistant anti-corrosion and wear-resistant coating, the distribution ratio of each component is shown in Table 11, Table 12, and Table 13:

[0109] Table 11 Waterborne zinc-rich primer formula

[0110]

[0111] Table 12 Waterborne Mica Iron Oxide Intermediate Paint Formula

[0112]

[0113] Table 13 water-based nano wear-resistant topcoat formula

[0114]

[0115]

[0116] The preparation and application method of the above-mentioned water-based high-temperature-resistant anti-corrosion and wear-resistant coating are as follows:

[0117] (1) Water-soluble silicone modified epoxy resin (self-made), zinc powder (500 mesh), phosphorus iron powder (500 mesh), defoamer (N-SiCO-2080 type, Guangzhou Touareg Trading Co., Ltd.), Leveling agent (N-SiCO-3038 type, Guangzhou Touareg Trading Co., Ltd.) and dispersant (BYK-A 530, BYK Chemicals) were added and mixed according to the formula, and the water-based rich Zinc primer mixture. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com