Nitrogen-phosphorus codoped carbon loaded molybdenum carbide or tungsten carbide catalyst and preparing method and application thereof

A tungsten carbide catalyst and co-doping technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of active center trouble synthesis, complicated manufacturing process, low yield, etc., and achieve structural Controllable, clear structure, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

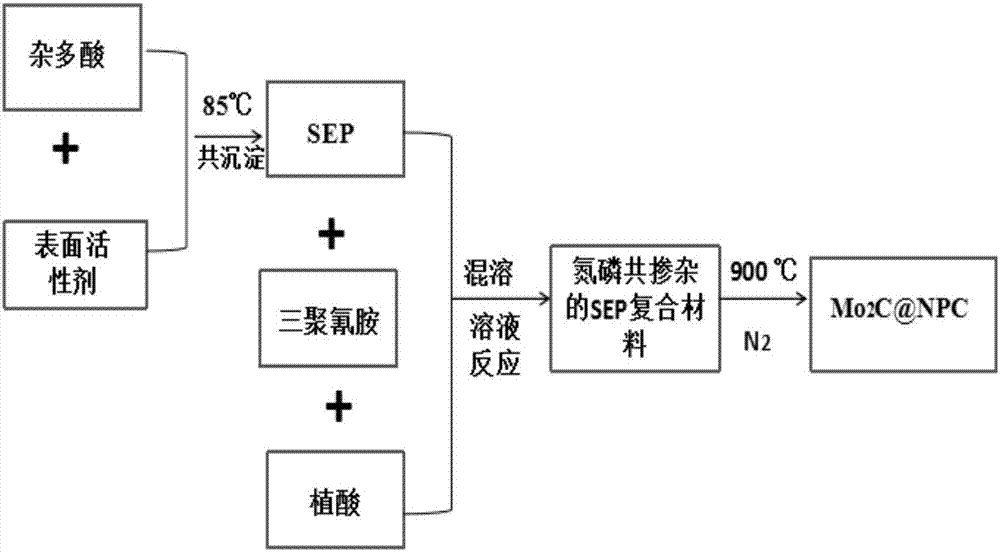

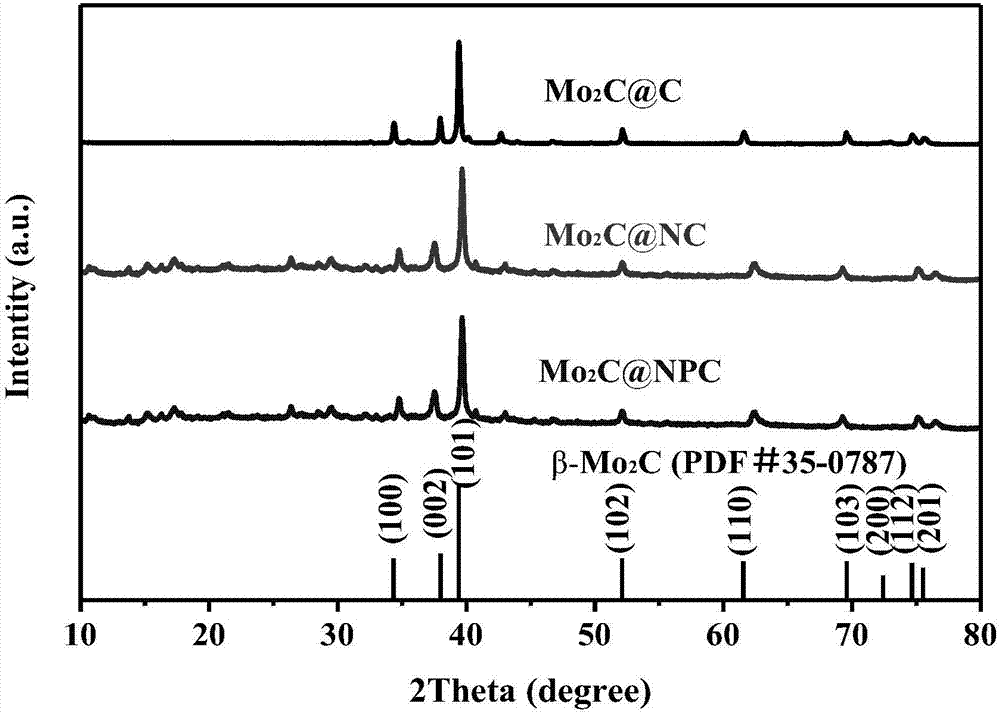

[0033] A preparation method of nitrogen-phosphorus co-doped carbon-supported molybdenum carbide catalyst, comprising the following steps:

[0034] (1) Heteropolyacid (NH 4 ) 4 [NiMo 6 o 24 h 6 ] (NiMo 6 ) synthesis: 5.00g (4.2mmol) (NH 4 ) 6 Mo 7 o 24 Dissolve in 80ml of deionized water, stir the solution and heat to boiling, then add 20mL containing 0.76g (3.0mmol) NiSO 4 ·7H 2 The aqueous solution of O is slowly added dropwise to the above boiling aqueous solution of ammonium molybdate, and recrystallized twice in water to obtain colorless crystals (NH 4 ) 4 [NiMo 6 o 24 h 6 ] (NiMo 6 ).

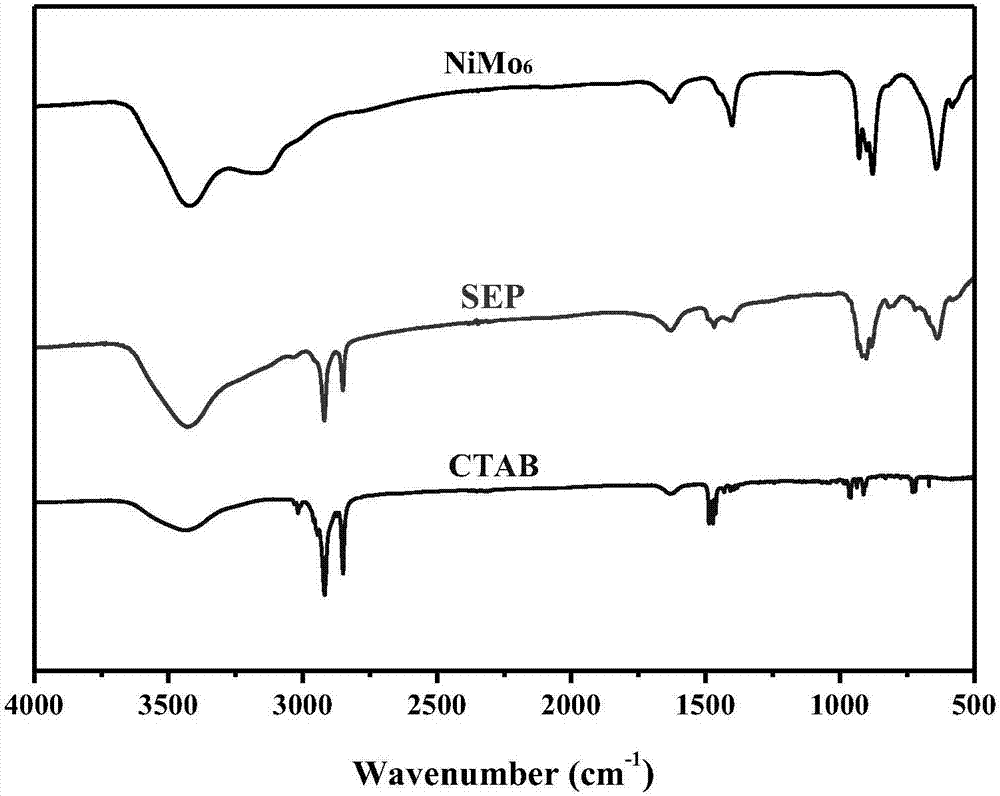

[0035] (2) Preparation of SEP (Surfactant encapsulate polyoxometalate, surfactant-encapsulated heteropolyacid) composite material: 1.08g (1.0mmol) (NH 4 ) 3 [NiMo 6 o 24 h 6 ] was dissolved in 80mL deionized water (A solution), 2.20g (10.0mmol) cetyltrimethylammonium bromide (surfactant) was dissolved in 20mL ethanol (B solution); at a temperature of 85 ° C, violently ...

Embodiment 2

[0042] A preparation method of nitrogen-phosphorus co-doped carbon-supported molybdenum carbide catalyst, comprising the following steps:

[0043] (1) Heteropolyacid (NH 4 ) 4 [(HPO 3 ) 2 Mo 5 o 15 ]·4H 2 Synthesis of O: Dissolve 4.1g of phosphorous acid (50mmol) in 70mL of water, then add 7mL of 15mol / L ammonia water (105mmol), heat the solution to boiling, and add 14.4g of MoO to the solution in small amounts for several times 3 (100mol), after 40-45min the powder was dissolved, the solution was filtered, the filtrate was boiled and evaporated to reduce the volume to 20-25mL, then cooled to room temperature, the crystalline powder was collected by filtration, washed with 7mL of ice water, dried in the air to obtain colorless The crystal is (NH 4 ) 4 [(HPO 3 ) 2 Mo 5 o 15 ]·4H 2 O.

[0044] (2) Preparation of SEP (Surfactant encapsulate polyoxometalate, surfactant-encapsulated heteropolyacid) composite material: 0.54g (0.5mmol) (NH 4 ) 4 [(HPO 3 ) 2 Mo 5 o ...

Embodiment 3

[0049] A preparation method of nitrogen-phosphorus co-doped carbon-supported molybdenum carbide catalyst, comprising the following steps:

[0050] (1) Heteropolyacid (NH 4 ) 6 [NiMo 9 o 32 ]·6H 2 Synthesis of O: 10 mL of Ni(NO 3 ) 2 and 0.1mol / L (NH 4 ) 2 Mo 7 o 24 The mixed solution was heated to 70°C, then 10 mL of ammonium persulfate solution with a concentration of 0.01 mol / L was added, and 0.1 mol / L of H 2 SO 4 The pH of the reaction system was adjusted to 4.4, and then the solution was boiled for half an hour. The solution was finally cooled slowly overnight to obtain black-red crystals. The crude product was obtained by suction filtration, and then the crude product was recrystallized 3-5 times, dried at 60°C, and the obtained colorless crystal was (NH 4 ) 6 [NiMo 9 o 32 ]·6H 2 O.

[0051] (2) Preparation of SEP (Surfactant encapsulate polyoxometalate, surfactant-encapsulated heteropolyacid) composite material: 1.08g (1.0mmol) (NH 4 ) 3 [NiMo 6 o 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com