Nano cerium oxide with core-shell structure and preparation method thereof

A nano-cerium oxide, core-shell structure technology, applied in nano-structure manufacturing, chemical instruments and methods, nanotechnology and other directions, can solve the problems of high reagent cost, complex synthesis process, small specific surface area of cerium oxide, etc. Simple preparation process and easily controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

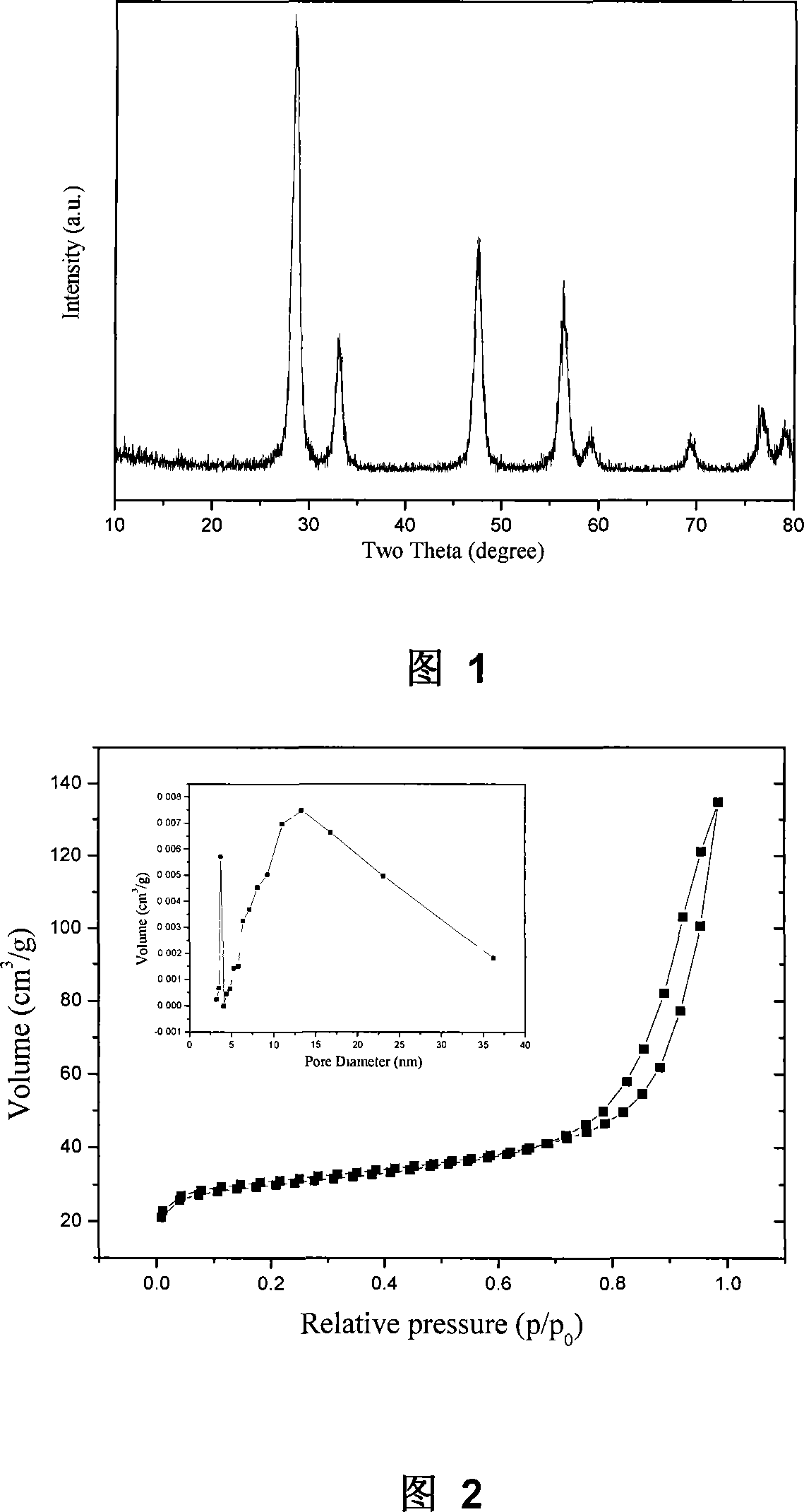

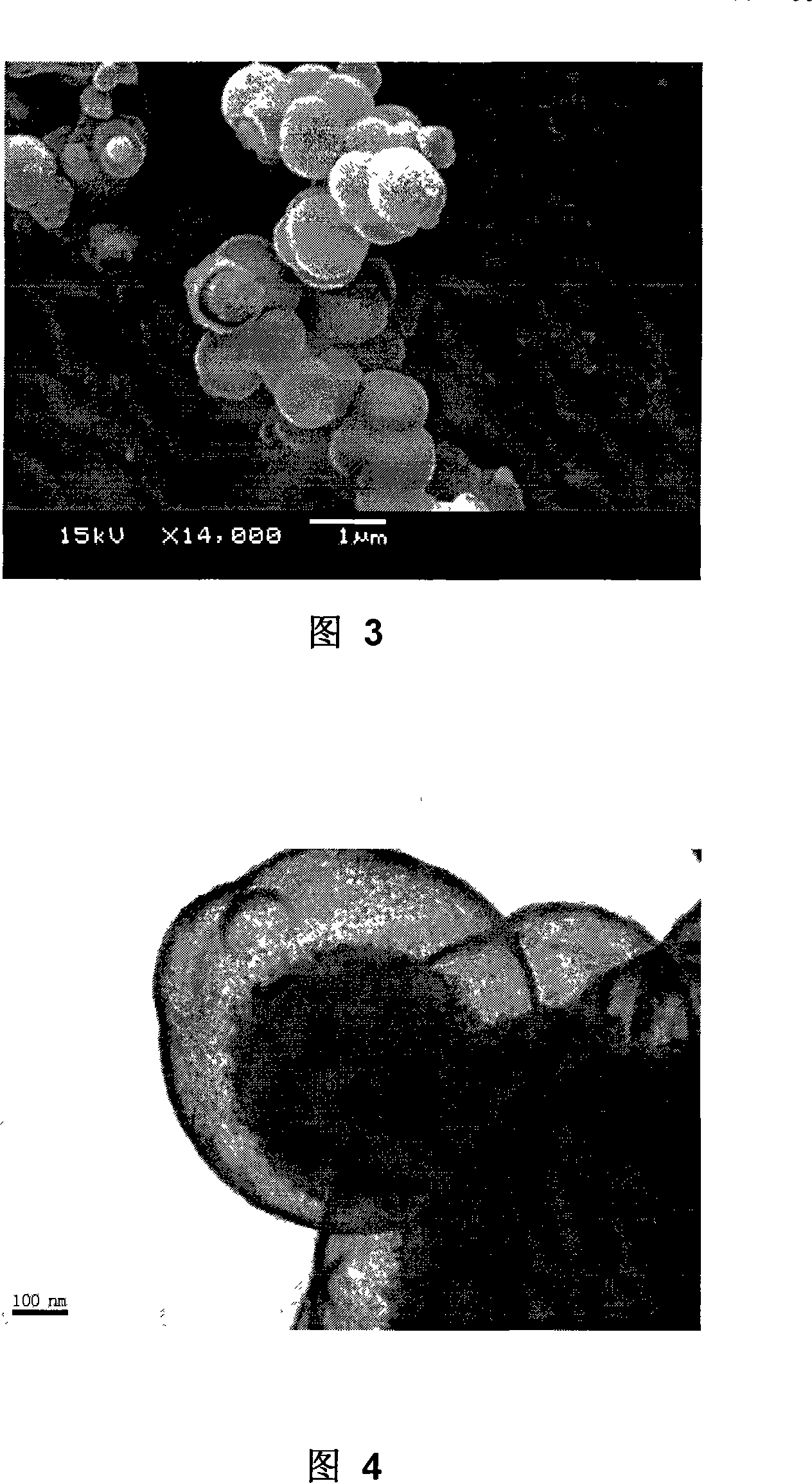

[0020] While stirring, make a mixed solution of 10mL glycerol, 10mL ether, 1.5mL water and 20mL ethanol, then add 2mmol of cerium ammonium nitrate to the solution, stir until colorless, then transfer to 50mL of water In a hot kettle, heat at 160°C for 24 hours, filter the product, wash with deionized water and absolute ethanol three times, dry at 80°C for 24 hours, and then roast in a muffle furnace at 400°C for 4 hours to obtain Nano cerium oxide with core-shell structure, its specific surface area is 105.5cm 2 / g. The X-ray diffraction pattern is shown in Figure 1, the nitrogen adsorption-desorption isotherm and BJH pore size distribution are shown in Figure 2, and the scanning electron microscope and transmission electron microscope pictures are shown in Figure 3 and Figure 4.

Embodiment 2

[0022] While stirring, make a mixed solution of 10mL glycerol, 4mL cyclohexane, 1.5mL water and 20mL ethanol, then add 2mmol of cerium ammonium nitrate to the solution, stir until colorless, then transfer to 50mL In a hydrothermal kettle, heated at 160°C for 72 hours, the product was suction filtered, washed three times with deionized water and absolute ethanol, dried at 80°C for 18 hours, and then roasted in a muffle furnace at 400°C for 4 hours. Obtain nano cerium oxide with core-shell structure, its specific surface area is 98.3cm 2 / g.

Embodiment 3

[0024] While stirring, make a mixed solution of 1.08g of glucose, 10mL of ether, 10mL of water and 20mL of ethanol, then add 2mmol of cerium ammonium nitrate into the solution, stir until colorless, then transfer to a 50mL hydrothermal kettle In 160°C hydrothermal treatment for 48h, the product was suction filtered, washed three times with deionized water and absolute ethanol respectively, dried at 80°C for 18h, and then roasted in a muffle furnace at 400°C for 4 hours to obtain a core-shell Structured nano cerium oxide with a specific surface area of 72.7 cm 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com