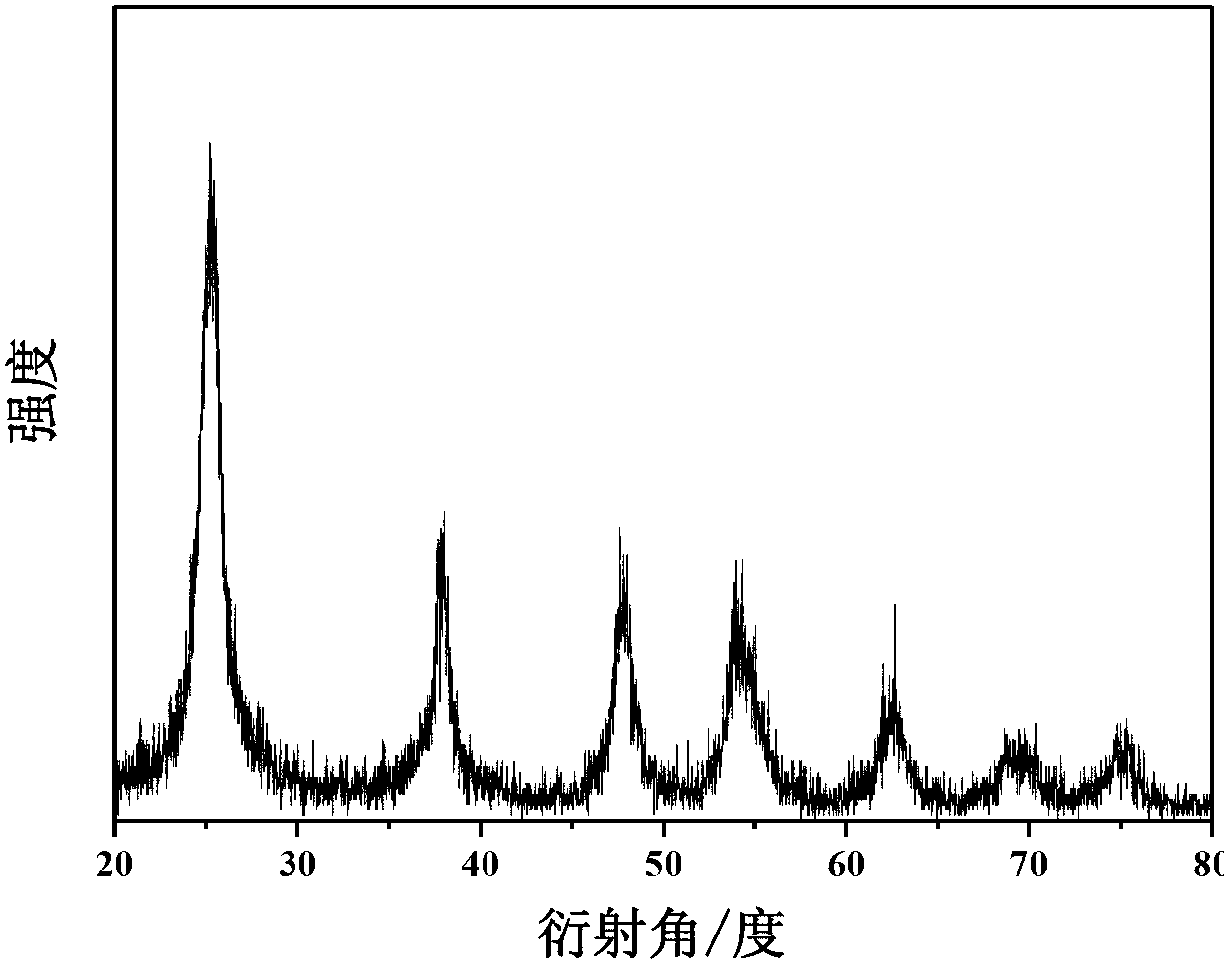

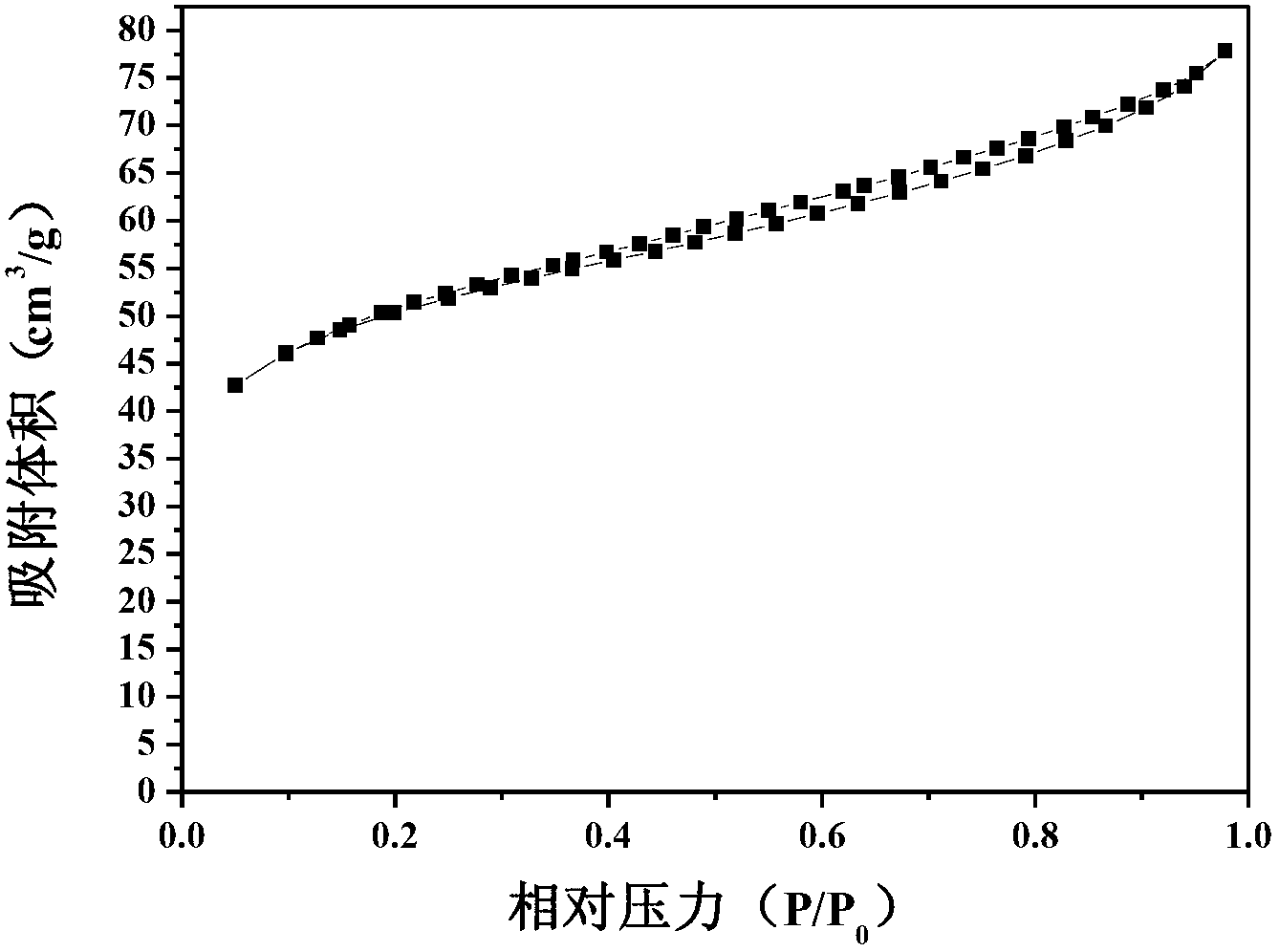

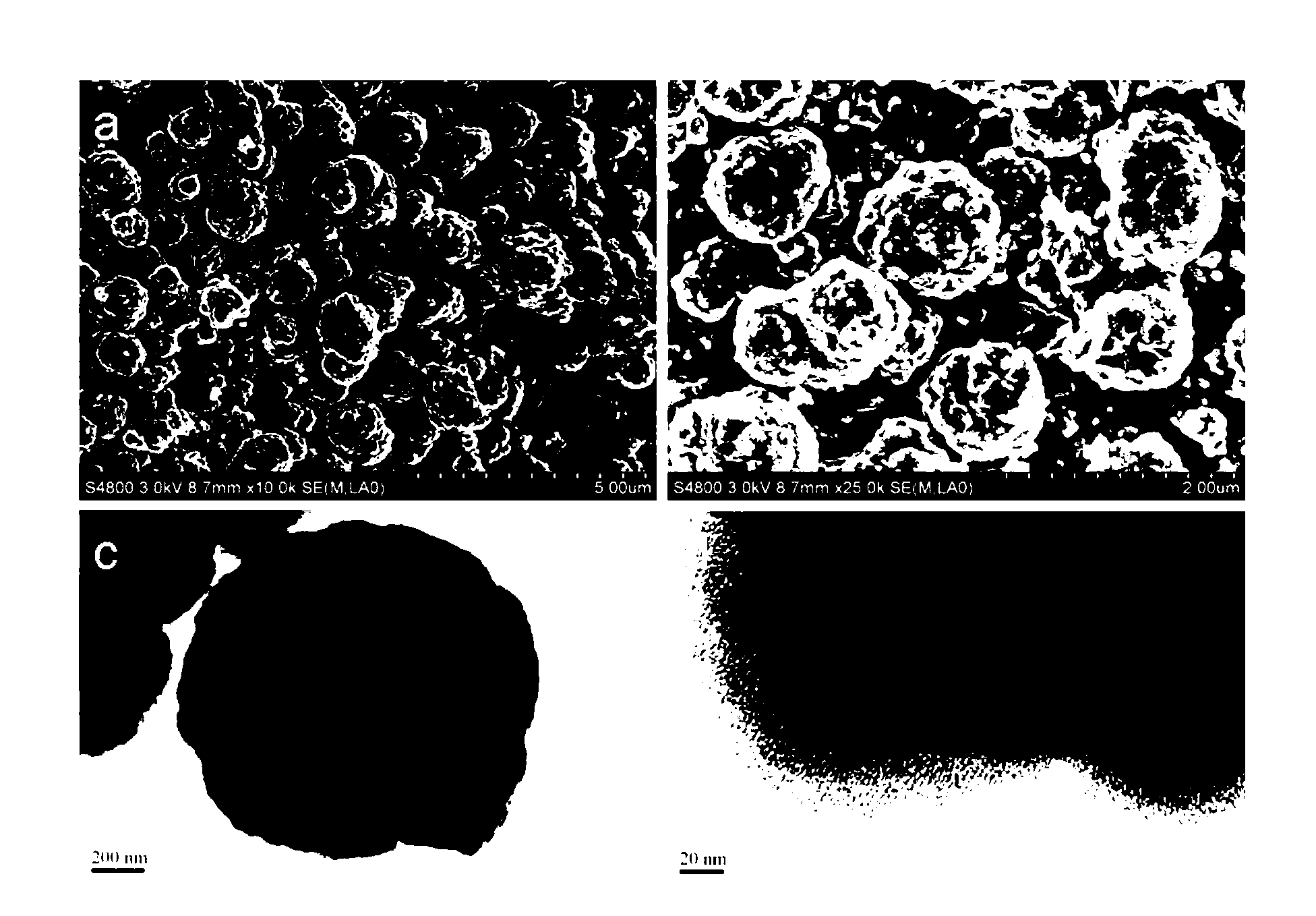

Ti<3+>-self-doped anatase titanium-oxide photocatalyst with large specific surface area, and synthetic method and applications thereof

A technology with large specific surface area and photocatalyst, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low total efficiency of converting light energy into hydrogen energy, It is not conducive to the separation of photogenerated electrons and holes, affecting the photon quantum efficiency, etc., to achieve the effect of improving the photocatalytic hydrogen production quantum efficiency, easy structure control, and high product purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 8mL of water in a 50mL beaker, drop into 2.0mL (2.4mmol) of TiCl 3 , to obtain a mixed solution (0.24mol / L) with a total volume of 10mL, which was transferred to a microwave reactor after stirring evenly. The heating rate was 24°C / min, the maximum microwave power was 800W, the temperature was raised to 150°C and kept at this temperature for 0 min, cooled to room temperature, washed with water until neutral, centrifuged and vacuum-dried to obtain sample A.

[0022] Weigh 50 mg of sample A into a beaker, add 60 mL of water, 20 mL of methanol and 128 μL (0.02 mol / L) of chloroplatinic acid solution, stir and disperse evenly. Place it under a 300W xenon lamp for 30-40min. Wash three times with water and alcohol respectively, and dry in vacuum at 80-90°C for 4h.

Embodiment 2

[0024] Take 8.5mL of water in a 50mL beaker, drop into 1.5mL (1.8mmol) of TiCl 3 , to obtain a mixed solution (0.18mol / L) with a total volume of 10mL, which was transferred to a microwave reactor after stirring evenly. The heating rate is 24°C / min, the maximum microwave power is 800W, the temperature is raised to 150°C and kept at this temperature for 0 min, cooled to room temperature, washed with water until neutral, centrifuged and vacuum-dried to obtain sample A.

[0025] Weigh 50 mg of sample A into a beaker, add 60 mL of water, 20 mL of methanol and 128 μL (0.02 mol / L) of chloroplatinic acid solution, stir and disperse evenly. Placed under a 300W xenon lamp for 30min. Wash three times with water and alcohol respectively, and dry in vacuum at 80°C for 4h.

Embodiment 3

[0027] Take 9.0mL of water in a 50mL beaker, drop into 1.0mL (1.2mmol) of TiCl 3 , to obtain a mixed solution (0.12mol / L) with a total volume of 10mL, which was transferred to a microwave reactor after stirring evenly. The heating rate was 24°C / min, the maximum microwave power was 800W, the temperature was raised to 150°C and kept at this temperature for 0 min, cooled to room temperature, washed with water until neutral, centrifuged and vacuum-dried to obtain sample A.

[0028] Weigh 50 mg of sample A into a beaker, add 60 mL of water, 20 mL of methanol and 128 μL (0.02 mol / L) of chloroplatinic acid solution, stir and disperse evenly. Placed under a 300W xenon lamp for 30min. Wash three times with water and alcohol respectively, and dry in vacuum at 80°C for 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com