Silver nano lattice surface enhanced raman active substrate and preparation method thereof

A surface-enhanced Raman and active substrate technology, applied in Raman scattering, nanotechnology, material excitation analysis, etc., can solve the problems of affecting the spectral stability of adsorbed molecules, expensive equipment, and high preparation costs, and achieve significant surface Raman enhancement Effect, enhanced signal uniformity and stability, easy for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

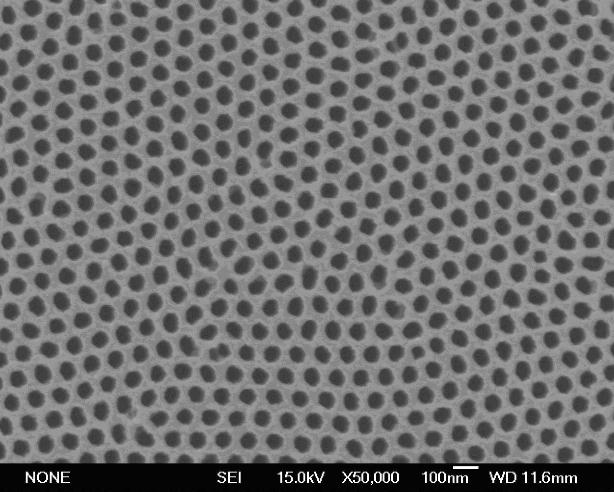

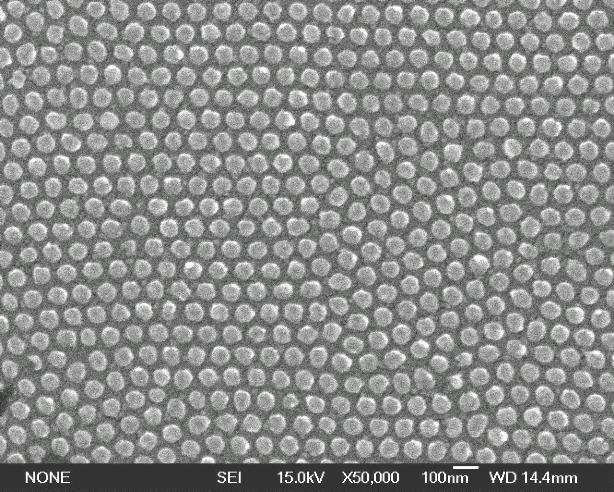

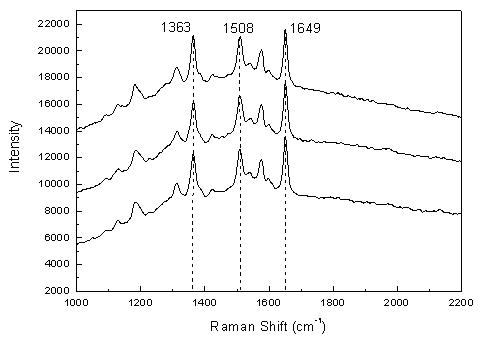

[0027] Embodiment 1: In this embodiment, UTAM is used as a template to prepare a large-area ordered and uniform Ag nanoparticle lattice on a Si substrate, and a 1 × 10 -7 M's rhodamine (rhodamine 6G, R6G) was used as the probe molecule for the surface Raman spectrum test. First, a 0.2 mm thick 99.999% aluminum sheet was ultrasonically cleaned with acetone for 30 min, annealed at 450-550 °C under nitrogen protection, and then placed in a mixture of ethanol and perchloric acid (volume ratio 1:9) at a temperature of 0 °C under constant flow. Electrochemical polishing under the condition of (750 mA) to prepare a spare aluminum sheet. The pretreated spare aluminum sheet was oxidized in 0.3 M oxalic acid at 40 V for 12 h at 4°C, taken out, and placed in a mixed solution of 1.8w% chromic acid and 6w% phosphoric acid with a volume ratio of 1:1. Corrosion at a temperature of 60°C for 10 h; rinsed repeatedly with deionized water, then placed in an electrolytic cell, and carried out sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com