Multi-shell-layer metal oxide hollow ball and preparation method thereof

A technology of hollow spheres and oxides, which is applied in the direction of oxide/hydroxide preparation, rare earth metal compounds, chemical instruments and methods, etc., can solve the problems that are difficult to apply to the synthesis of metal oxide multi-shell hollow spheres, and achieve excellent performance , good structural stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

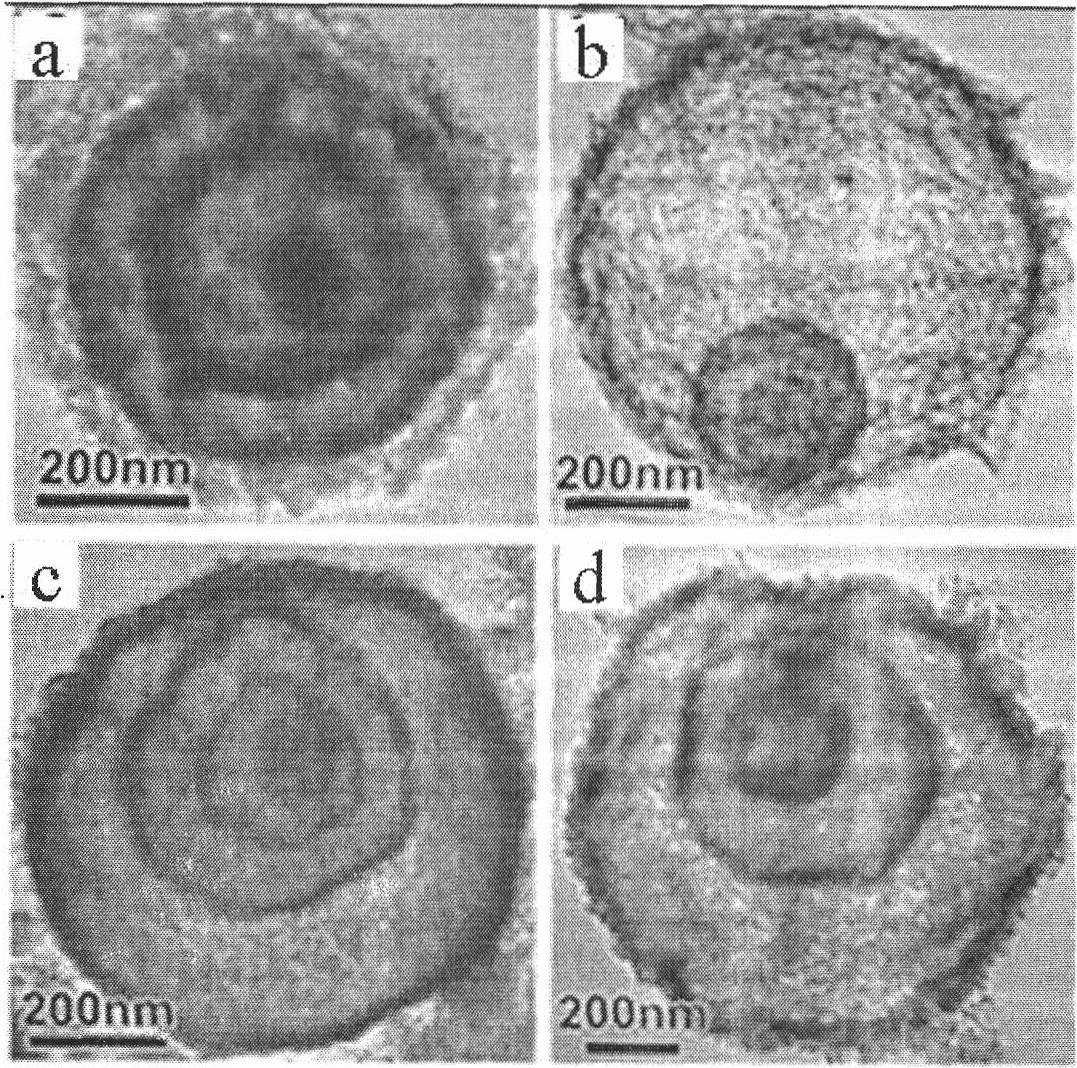

[0024] Firstly, the carbon sphere template was prepared with sucrose by the hydrothermal method: 5.5 g of sucrose was dissolved in 10 ml of water, and the solution was put into a reaction kettle, and heated in water at 200 ° C for 80 min. After the product was filtered, washed and dried, the obtained carbon About 0.4 g of the balls was placed in 10 ml of deionized water, and ultrasonicated for 3 minutes to obtain a suspension of carbon balls.

[0025] Impregnation: 8g, 16g, 20g of Fe(NO 3 ) 3 9H 2 O was added to the above suspension of carbon spheres and stirred evenly (that is, the concentration of the metal salt was 2 mol / L, 3 mol / L, 5 mol / L respectively), then ultrasonicated for 15 min, and then stirred at room temperature for 5 h, and the suspension was filtered and washed , and then dried at 100°C for 12 hours, and the obtained powder material was carbon spheres adsorbed with metal ions.

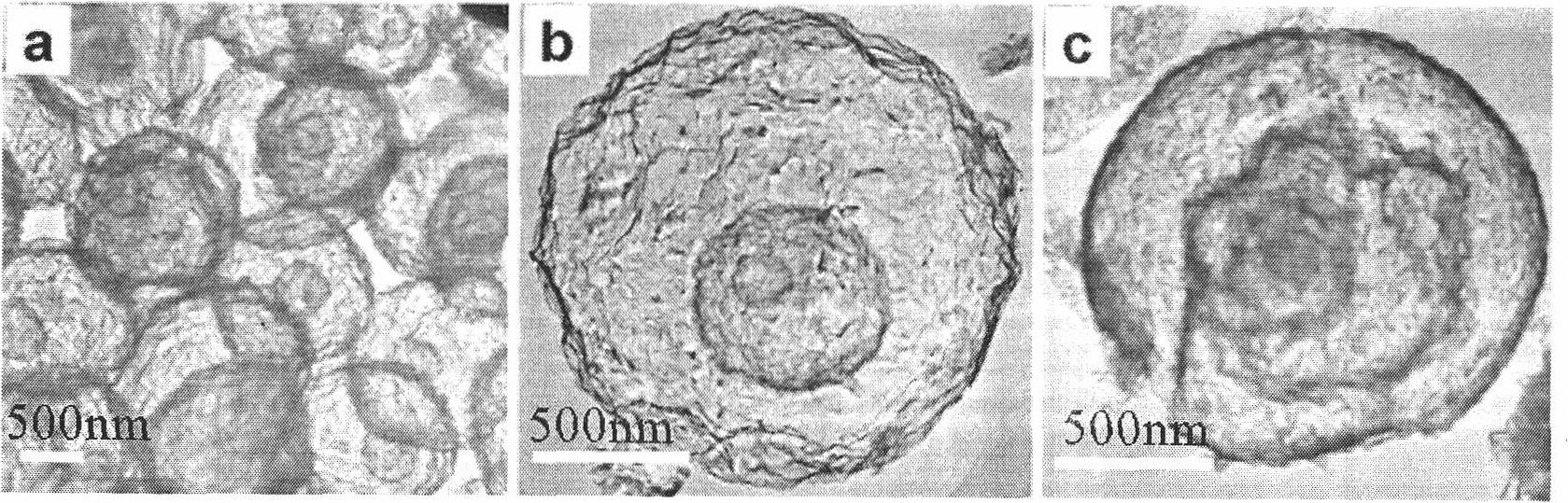

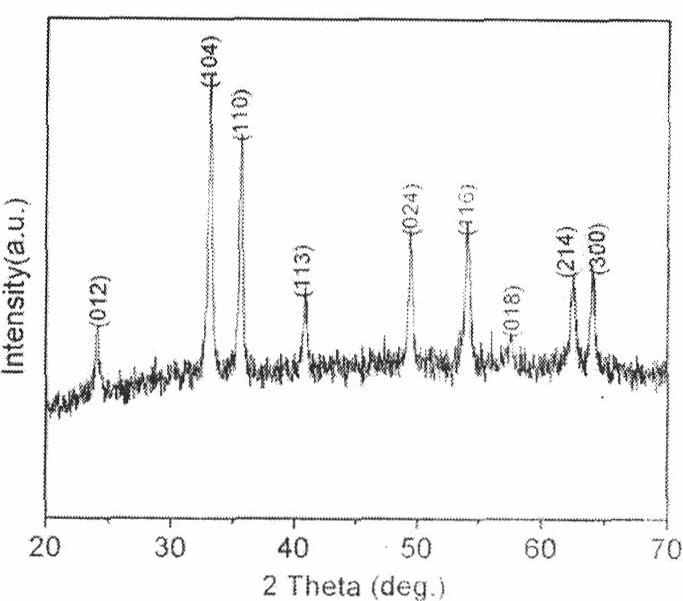

[0026] Heat treatment: Finally, the obtained powder was heated to 500° C. at a r...

Embodiment 2

[0029] First, use glucose to prepare carbon sphere templates by hydrothermal method: dissolve 11 g of glucose in 10 ml of water, put the solution into a reaction kettle, and heat it in water at 160°C for 50 minutes. After the product is filtered, washed, and dried, the obtained carbon spheres About 0.4 g was put into 10 ml of deionized water, and ultrasonicated for 30 min to obtain a suspension of carbon spheres.

[0030] Impregnation: 5.5g of Zn(CH 3 COO) 2 ·6H 2O was added to the above suspension of carbon spheres and stirred evenly (that is, the metal salt concentration was 2.5 mol / L), then ultrasonicated for 15 min, and then stirred at room temperature for 20 h, the suspension was filtered and washed, and then dried at 100°C for 12 h. The obtained powdery material is carbon spheres adsorbed with metal ions.

[0031] Heat treatment: Finally, the obtained powder was heated to 800° C. at a rate of 5° C. / min in a muffle furnace in an air atmosphere and kept for 3 hours to r...

Embodiment 3

[0034] Firstly, the carbon sphere template was prepared with sucrose by the hydrothermal method: 5.5 g of sucrose was dissolved in 10 ml of water, and the solution was put into a reaction kettle, and heated in water at 200 ° C for 80 min. After the product was filtered, washed and dried, the obtained carbon About 0.4 g of the balls was placed in 10 ml of deionized water, and ultrasonicated for 15 minutes to obtain a suspension of carbon balls.

[0035] Impregnation: 8.7g of Co(NO 3 ) 2 ·6H 2 O was added to the above suspension of carbon spheres and stirred evenly (that is, the metal salt concentration was 3 mol / L), then ultrasonicated for 15 min, and then stirred at room temperature for 10 h, the suspension was filtered and washed, and then dried at 100°C for 12 h to obtain The powdered material is carbon spheres adsorbed with metal ions.

[0036] Heat treatment: Finally, the obtained powder was heated up to 400°C at a rate of 1°C / min in a muffle furnace in an air atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com