Magnesia-alumina spinel structure heat insulation integral composite brick and preparation method thereof

A technology of magnesia-aluminum spinel and composite bricks, which is applied in the field of refractory composite bricks and its preparation, can solve the problems of high thermal conductivity, low refractoriness, and low strength, and achieve the effects of prolonging the service life of equipment and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

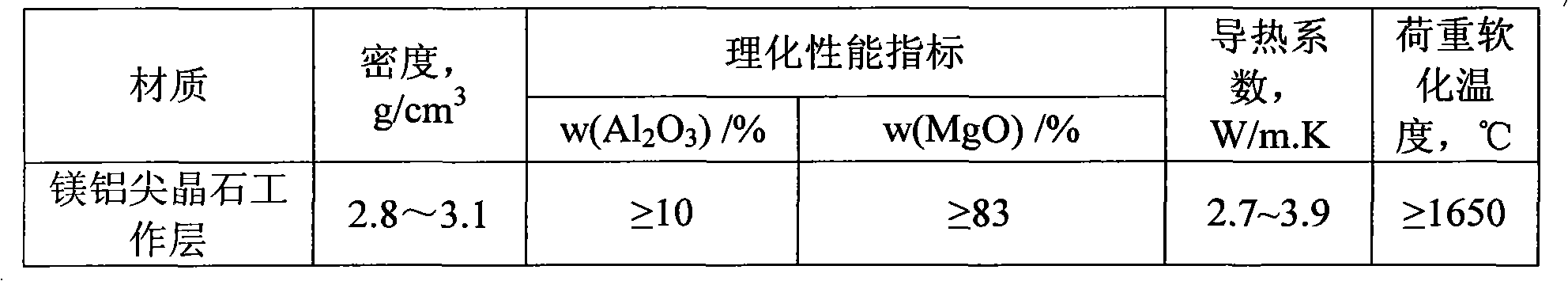

[0032] This embodiment adopts dense magnesia-aluminum refractory material and aluminum oxide hollow sphere layered composite, the raw materials and mass percentages used in the heavy working layer are: 1-3mm fused magnesia 35%, less than 1mm fused magnesia Magnesia 25%, no more than 325 mesh fused magnesia 20%, less than 1mm fused spinel 15%, no more than 325 mesh fused spinel 5%, plus 3% sulfurous acid pulp waste liquid; light work The raw materials used in the layer and their mass percentages are: 65% aluminum oxide hollow spheres, α-Al 2 o 3 Micropowder 35%, plus phosphate binder as α-Al 2 o 3 35% of the mass percentage of fine powder.

[0033] The preparation process comprises the following steps:

[0034] (1) Batching: The batching process of the heavy working layer is to mix the powder not larger than 325 mesh in proportion and mix it evenly in the ball mill, and then add the mixed powder after the rest of the aggregate particles and the binder are mixed evenly , st...

Embodiment 2

[0038]This embodiment is made of dense magnesium-aluminum refractory materials and aluminum-magnesium hollow spheres. The raw materials used in the heavy working layer and their mass percentages are: 1-3mm fused magnesia 45%, less than 1mm fused magnesia Magnesia 15%, no more than 325 mesh fused magnesia 15%, less than 1mm fused spinel 10%, no more than 325 mesh fused spinel 15%, plus 5% yellow dextrin solution; light heat insulation The raw materials used in the layer and their mass percentages are: 38% aluminum-magnesium hollow spheres, α-Al 2 o 3 Micropowder 62%, plus aluminum dihydrogen phosphate binder as α-Al 2 o 3 31% of the mass percentage of fine powder.

[0039] The preparation process comprises the following steps:

[0040] (1) Batching: The batching process of the heavy working layer is to mix the powder not larger than 325 mesh in proportion and mix it evenly in the ball mill, and then add the mixed powder after the rest of the aggregate particles and the bind...

Embodiment 3

[0044] This embodiment is made of dense magnesium-aluminum refractory material and corundum hollow sphere layered compound. The raw materials and their mass percentages used in the heavy working layer are: 1-3mm fused magnesia 45%, less than 1mm fused magnesia Sand 15%, no more than 325 mesh fused magnesia 25%, less than 1mm fused spinel 5%, no more than 325 mesh fused spinel 10%, plus lignosulfonate 3%; used in light working layer The raw materials and their mass percentages are: corundum hollow spheres 60%, α-Al 2 o 3 40% fine powder, plus aluminum sulfate binder as α-Al 2 o 3 35% of the mass percentage of fine powder.

[0045] The preparation process comprises the following steps:

[0046] (1) Batching: The batching process of the heavy working layer is to mix the powder not larger than 325 mesh in proportion and mix it evenly in the ball mill, and then add the mixed powder after the rest of the aggregate particles and the binder are mixed evenly , stirred for 10 to 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com