Co3O4 nano hollow sphere material and preparation method and application thereof

A hollow sphere and nanotechnology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of increased charge-discharge cycle life, irreversible capacity decay, etc. Effects of chemical actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

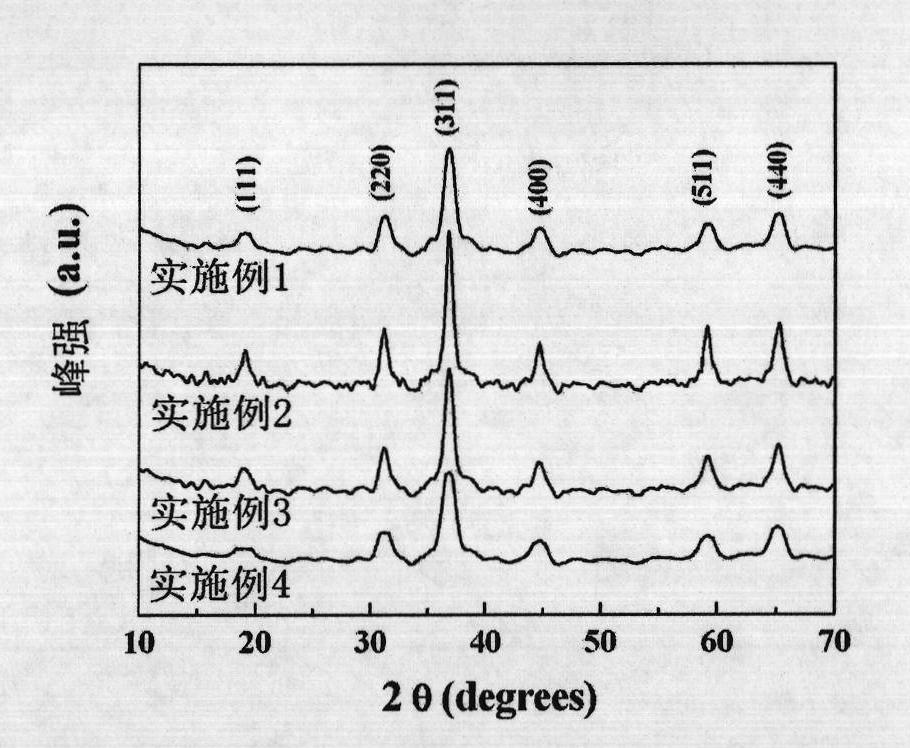

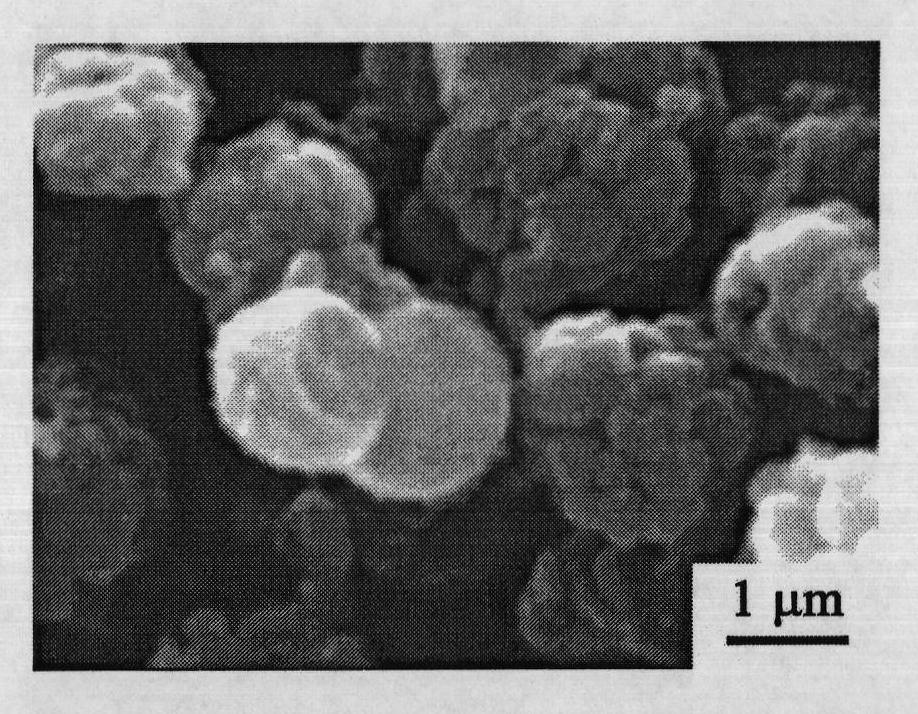

Embodiment 1

[0068] Get 5.29g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 1.28g hexamethylenetetramine (HMT, C 6 h 12 N 4 ), 1.79g sodium citrate (C 6 h 5 Na 3 o 7 2H 2 O) was added to 50ml deionized water, Co(NO 3 ) 2 :HMT:C 6 h 5 Na 3 o 7 The molar ratios are 6:3:2, and the entire addition process is carried out under magnetic stirring. After stirring for 60 minutes, the entire mixed solution was moved into a polytetrafluoroethylene-lined autoclave with a filling degree of 60%, reacted at a certain temperature (95° C.) for 23.5 hours, and then cooled naturally. The product was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 60°C to obtain a powdery mixed precursor; the powdery mixed precursor was heat-treated at 290°C for 3 hours in an air atmosphere to obtain Final Co 3 o 4 Material.

Embodiment 2

[0070] Get 5.29g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 2.51g hexamethylenetetramine (HMT, C 6 h 12 N 4 ), 1.79g sodium citrate (C 6 h 5 Na 3 o 7 2H 2 O) was added to 60ml deionized water, Co(NO 3 ) 2 :HMT:C 6 h 5 Na 3 o 7 The molar ratios are 3:3:1 respectively, and the whole adding process is carried out under magnetic stirring. After stirring for 30 minutes, the entire mixed solution was moved into a polytetrafluoroethylene-lined autoclave with a filling degree of 75%, reacted at a certain temperature (100° C.) for 24 hours, and then cooled naturally. The product was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 70°C to obtain a powdery mixed precursor; the powdery mixed precursor was heat-treated at 300°C for 3 hours in an air atmosphere to obtain Final Co 3 o 4 Material.

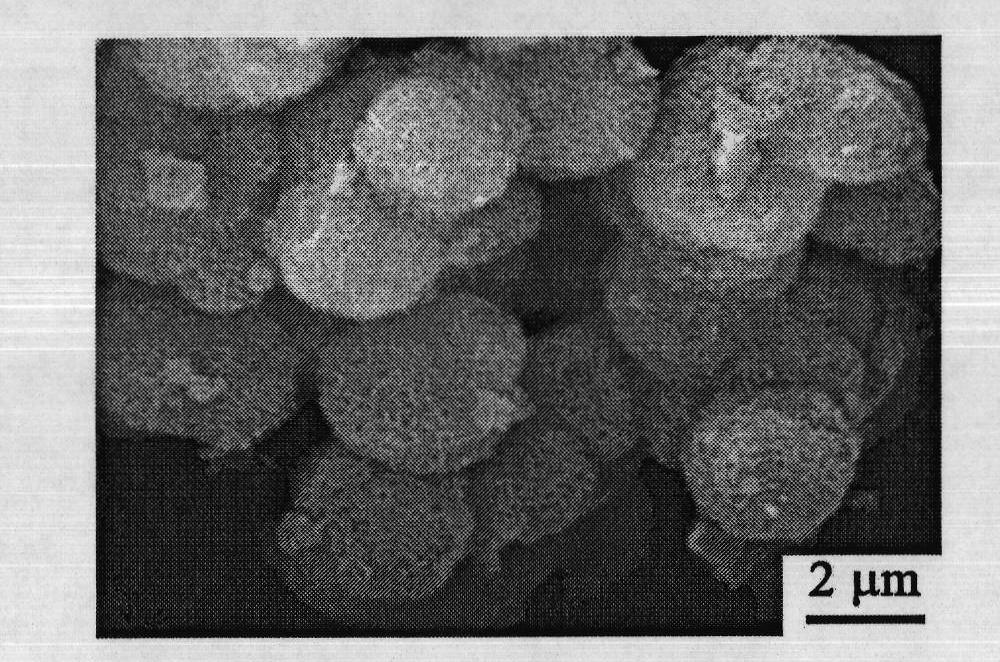

Embodiment 3

[0072] Get 5.29g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 5.10g hexamethylenetetramine (HMT, C 6 h 12 N 4 ), 1.17g citric acid (C 6 h 8 o 7 ) into 60ml deionized water, Co(NO 3 ) 2 :HMT:C 6 h 8 o 7 The molar ratios are 3:6:1 respectively, and the whole adding process is carried out under magnetic stirring. After stirring for 45 minutes, the entire mixed solution was moved into a polytetrafluoroethylene-lined autoclave with a filling degree of 70%, reacted at a certain temperature (100° C.) for 24 hours, and then cooled naturally. The product was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 80°C to obtain a powdery mixed precursor; the powdery mixed precursor was heat-treated at 300°C for 3 hours in an air atmosphere to obtain Final Co 3 o 4 Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com