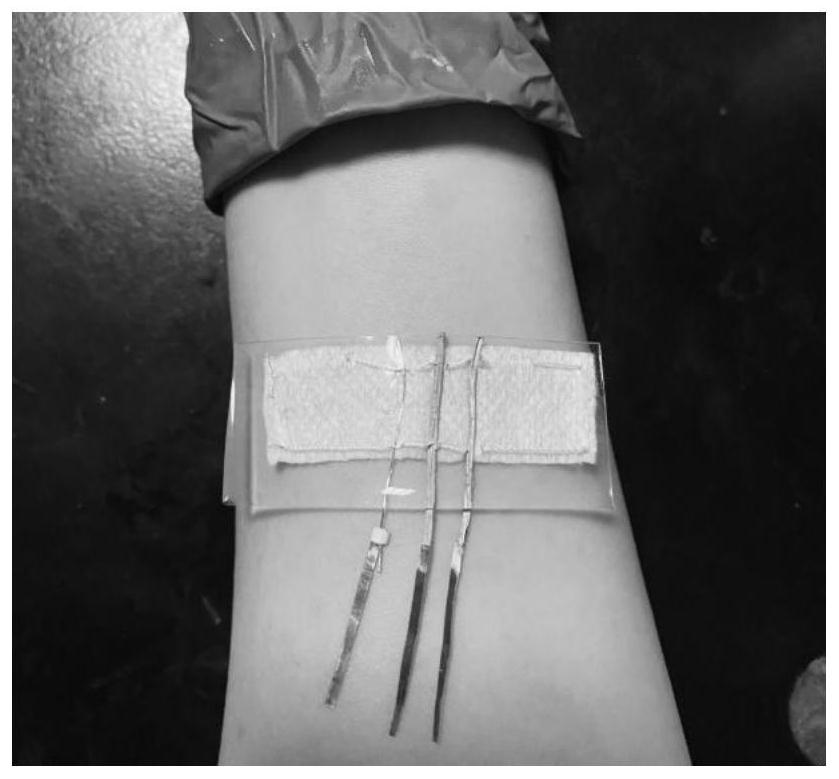

Preparation method of flexible wearable sweat glucose electrochemical sensor

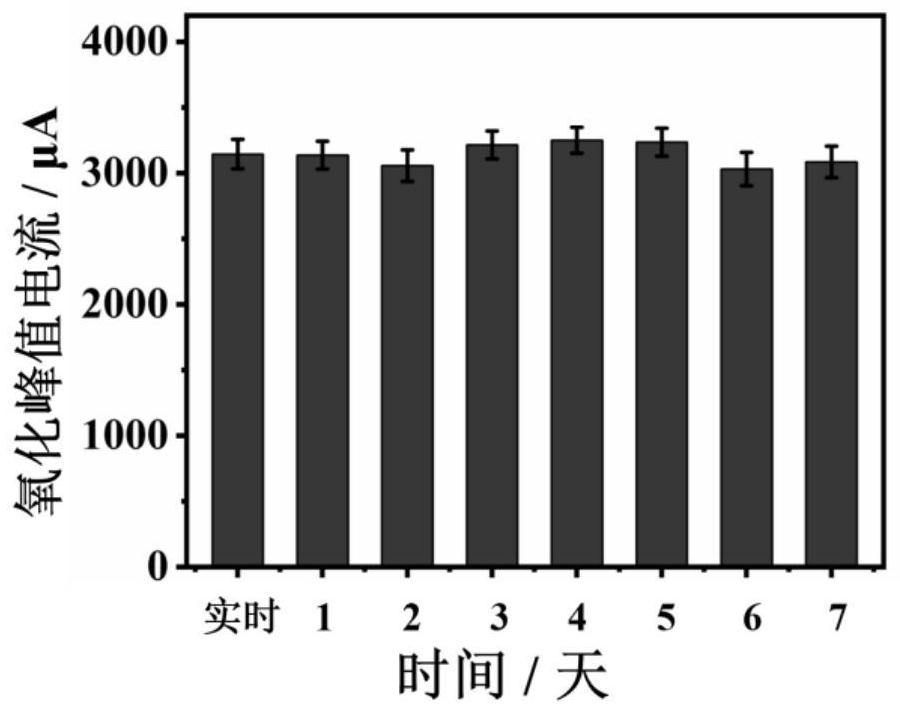

A wearable, glucose-based technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of patients' physical and psychological pain, and cannot realize continuous monitoring, and achieve low detection limit, good tensile performance, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Preparation of spinning solution:

[0019] Add 2 ml of N,N-dimethylacetamide (DMAC) to graphene and polyurethane (mass ratio of 1:5) and mix and stir to obtain a spinning solution.

[0020] 2. Preparation of polydimethylsiloxane:

[0021] In a mass ratio of 10:1, the polydimethylsiloxane prepolymer and the curing agent are mixed, and a crosslinking reaction occurs to form the polydimethylsiloxane.

[0022] 3. Preparation of flexible biosensors:

[0023] (1) Preparation of fiber electrode mold:

[0024] The polydimethylsiloxane prepolymer (PDMS) and the curing agent were mixed in a ratio of 10:1 and then degassed, then spin-coated on a glass slide, placed in an oven for 5 min and taken out. A 1mm capillary column was gently placed on the surface of the incompletely cured PDMS, placed in an oven to dry for 2 hours and taken out. After the PDMS was completely cured, the capillary was taken out, and a thin groove was formed on the surface of the PDMS to obtain a fiber...

Embodiment 2

[0038] Referring to the preparation method of Example 1, the difference is that in the preparation of rGO / PU fibers, the ratio of rGO to PU is adjusted.

[0039] The specific operations are as follows: rGO / PU with ratios of 0, 1:10, 1:5, 1:3, and 1:1 were mixed with 2 mL DMAC to obtain spinning solutions with different ratios.

Embodiment 3

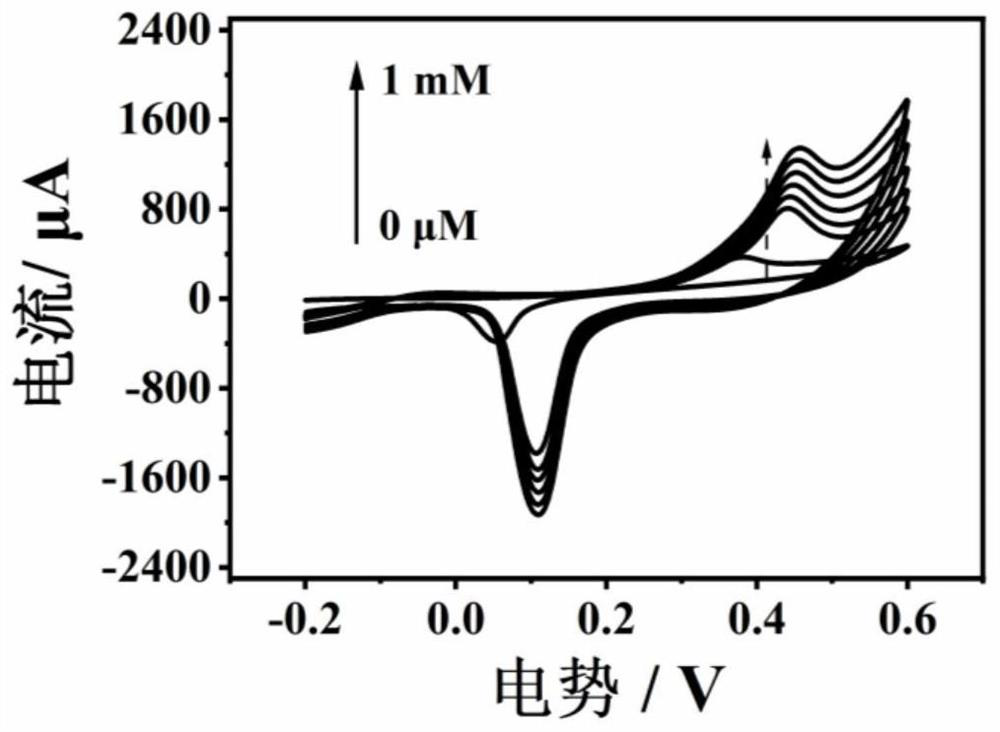

[0041] Referring to the preparation method of Example 1, the difference is that in the preparation of the working electrode, the concentration of Ni / Co-MOF in the Ni-Co MOF dispersion liquid is adjusted.

[0042] The details are as follows: 1.5mg, 3mg, 4.5mg, 6mg, 7.5mg of Ni-Co MOF powders were dissolved in 1 mL of Nafion ethanol solution with a concentration of 1%, and ultrasonicated for 5 minutes at room temperature until different Ni-Co MOF powders were formed. MOF concentration dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com