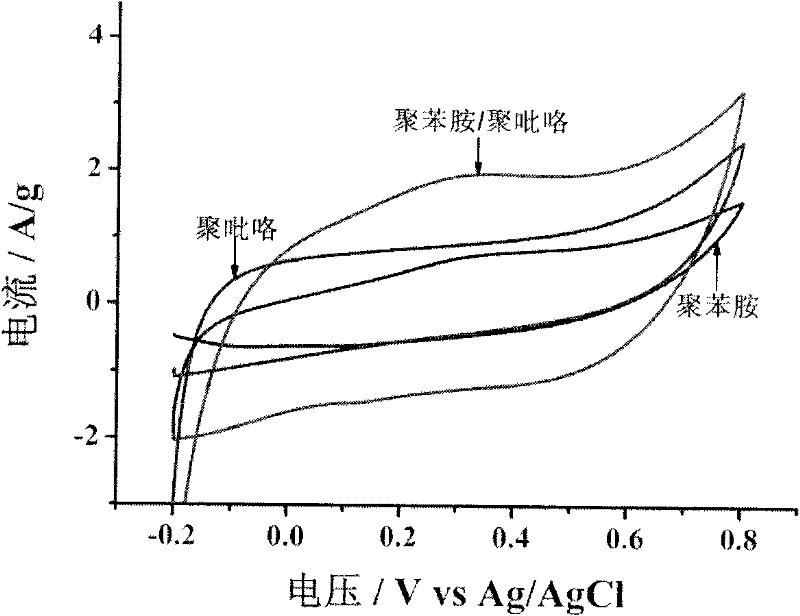

Preparation of polyaniline/polypyrrole composite nano fiber electrode materials with core-shell structure

A technology of composite nanofibers and core-shell structures, applied in the direction of conjugated synthetic polymer man-made filaments, etc., can solve the problems of complicated post-processing process, low synthesis yield and high production cost, and achieves a simple and easy-to-operate preparation method and low cost. , to avoid the effect of corrosion and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

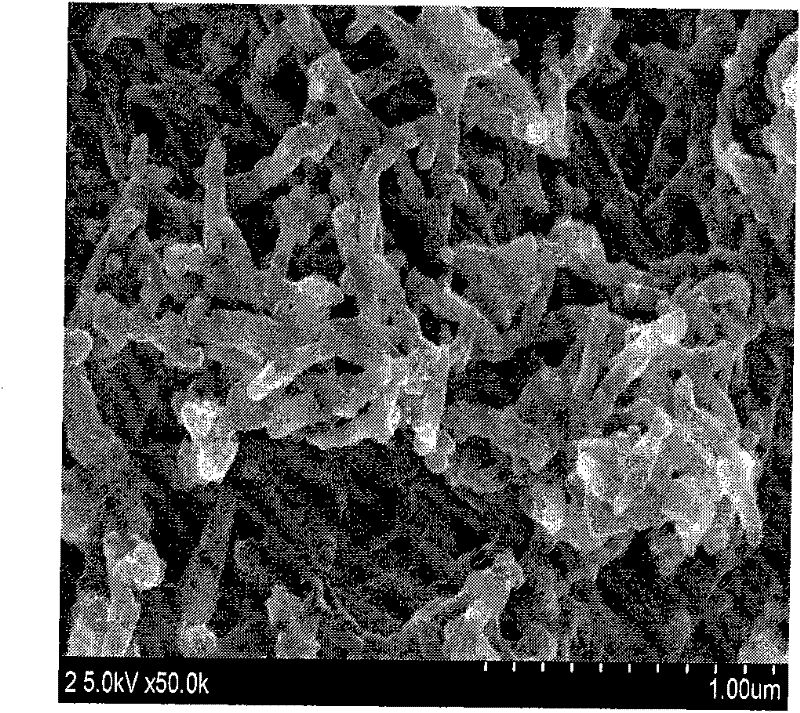

[0028] Accurately weigh 0.02mol of aniline and 0.02mol of ammonium persulfate and dissolve them in 100ml of 1M hydrochloric acid solution, mix the two solutions, shake at room temperature at a speed of once per second, and control the reaction time at 5min; the reaction product is centrifuged at a high speed and repeated washing to prepare polyaniline nanofibers.

[0029] Add the prepared polyaniline nanofibers into 100ml of 1M hydrochloric acid solution, sonicate for 30min, then add 0.005mol pyrrole monomer into the above mixture and sonicate for 30min, add ice cubes during sonication, keep the system temperature stable at 0°C, 0.005 mol ferric trichloride dissolved in 100 ml of 1M hydrochloric acid solution was slowly added dropwise to the mixed solution at a constant speed of 5 ml / min to react for 40 min. The reaction product was subjected to high-speed centrifugation and repeated washing, and dried in vacuum at 60°C for 24 hours. The prepared black powder was the polyanili...

Embodiment 2

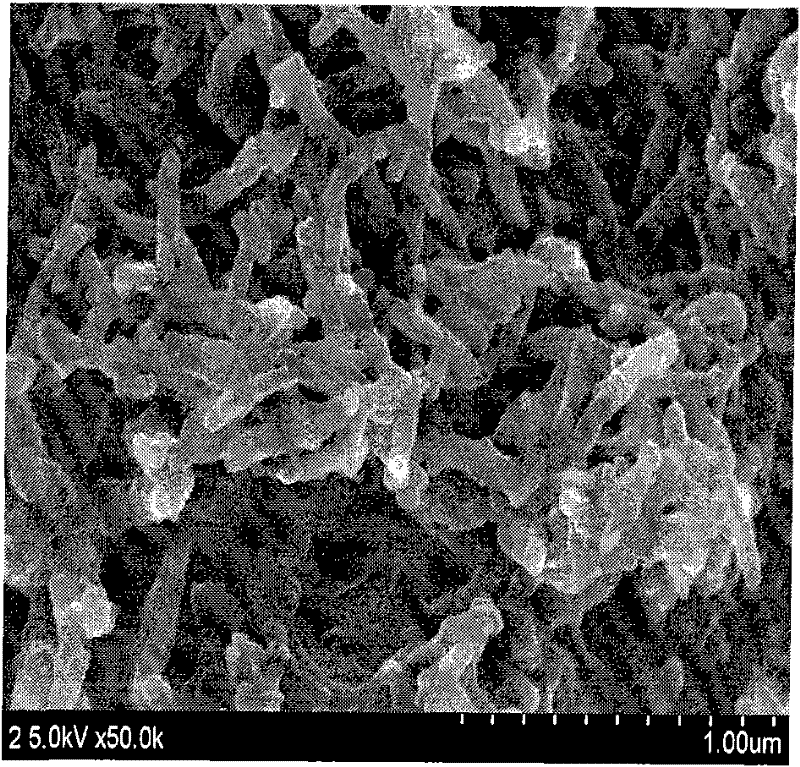

[0032] Accurately weigh 0.005mol aniline and 0.005mol ferric chloride and dissolve them in 100ml of 1M hydrochloric acid solution respectively, mix the two solutions, shake at room temperature at a speed of 3 times per second, and control the reaction time at 10min; Centrifuge and wash repeatedly to prepare polyaniline nanofibers.

[0033]Add the prepared polyaniline nanofibers into 100ml of 1M hydrochloric acid solution, sonicate for 30min, then add 0.005mol pyrrole monomer into the above mixture and sonicate for 30min, add ice cubes in the sonication, keep the system temperature stable at 0°C, 0.005 mol ferric trichloride dissolved in 100 ml of 1M hydrochloric acid solution was slowly added dropwise to the mixed solution at a constant speed of 5 ml / min to react for 40 min. The reaction product was subjected to high-speed centrifugation and repeated washing, and dried in vacuum at 60°C for 24 hours. The prepared black powder was the polyaniline / polypyrrole composite nanofiber...

Embodiment 3

[0036] Accurately weigh 0.02mol aniline and 0.02mol potassium dichromate and dissolve them in 100ml of 1M hydrochloric acid solution, mix the two solutions, shake at room temperature at a speed of 5 times per second, and control the reaction time at 20min; Centrifuge and wash repeatedly to prepare polyaniline nanofibers.

[0037] Add the prepared polyaniline nanofibers into 100ml of 1M hydrochloric acid solution, sonicate for 30min, then add 0.005mol pyrrole monomer into the above mixture and sonicate for 30min, add ice cubes in the sonication, keep the system temperature stable at 5°C, 0.005 mol ferric trichloride dissolved in 100 ml of 1M hydrochloric acid solution was slowly added dropwise to the mixed solution at a constant speed of 5 ml / min to react for 40 min. The reaction product was subjected to high-speed centrifugation and repeated washing, and dried in vacuum at 60°C for 24 hours. The prepared black powder was the polyaniline / polypyrrole composite nanofiber with cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com