Method for preparing ZnO/ZnFe2O4 compound nano hollow sphere

A technology of znfe2o4 and hollow spheres, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of complex process and high operation requirements, and achieve the effect of simple process requirements and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

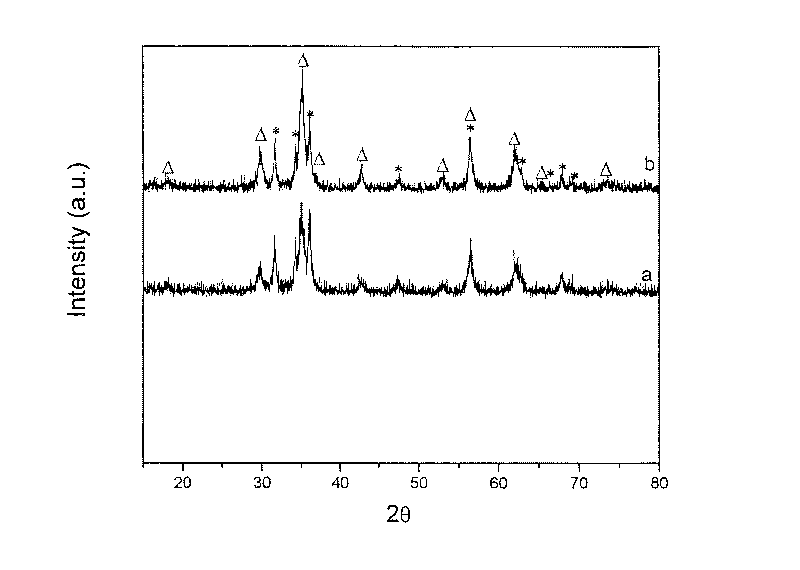

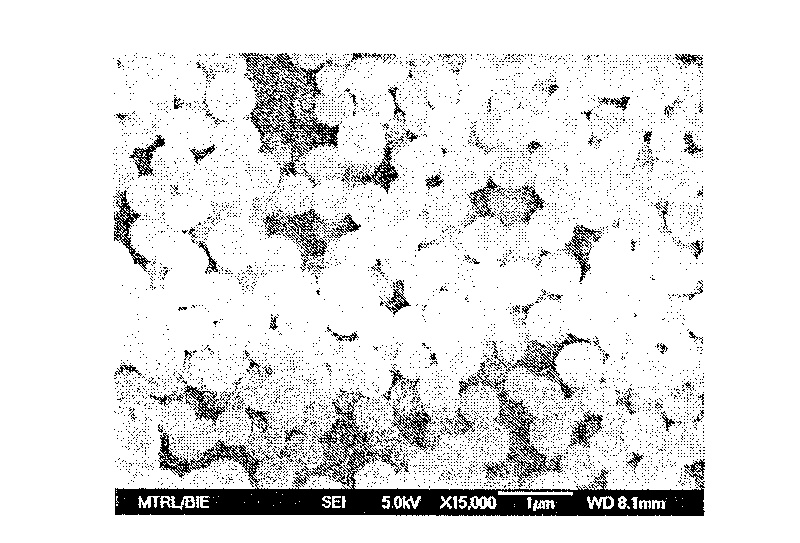

[0029] A kind of preparation ZnO / ZnFe 2 o 4 The method for composite nano hollow spheres, the steps are:

[0030] (1) Disperse 0.6 g of sucrose in 24 ml of water, stir and dissolve to form an aqueous solution of carbohydrate compounds;

[0031] (2) The prepared saccharide compound aqueous solution is put into a 30ml inner liner made of polytetrafluoroethylene, and the outer shell is made of steel;

[0032] (3) After sealing the reaction kettle, place it in an oven at 160°C for 20 hours, cool naturally, and centrifuge to obtain the product, wash the product three times with distilled water and absolute ethanol, and dry to obtain carbon nanospheres;

[0033] (4) Take 0.02 grams of the above-mentioned carbon nanospheres, disperse them in 20ml of ethanol, add 0.25 zinc acetate, 2mg ferric chloride and 0.25g sodium bicarbonate successively, and obtain an alcoholic solution containing carbon spheres after ultrasonic dispersion;

Embodiment 2

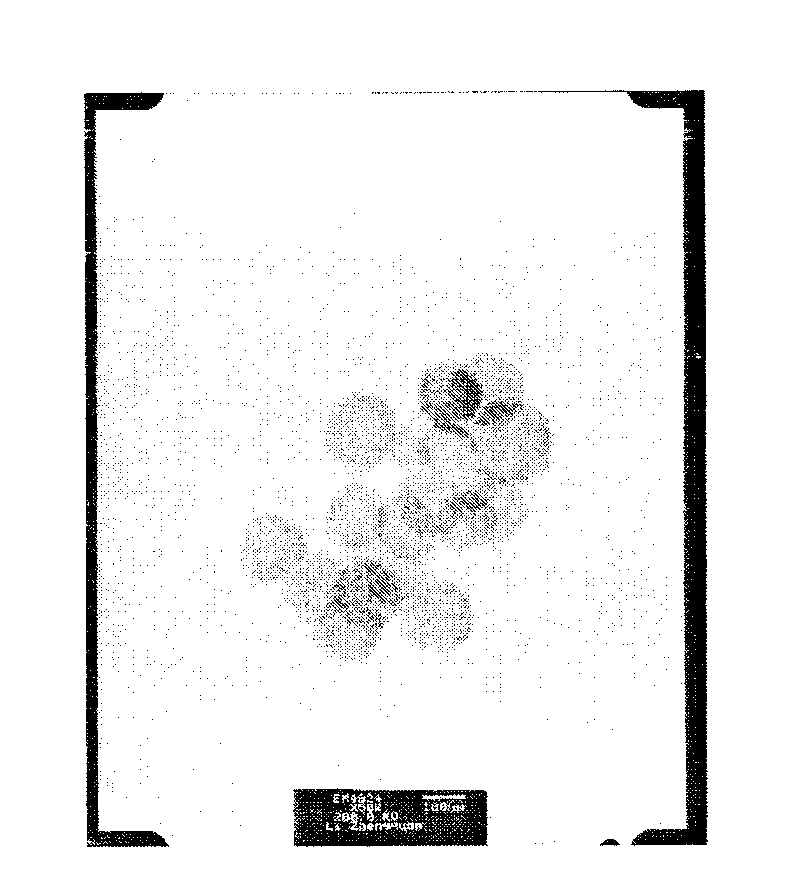

[0043] A kind of preparation ZnO / ZnFe 2 o 4 The method for composite nano hollow spheres, the steps are:

[0044] (1) Disperse 0.12 g of starch in 24 ml of water, stir and dissolve to form an aqueous solution of carbohydrate compounds;

[0045] (2) The prepared saccharide compound aqueous solution is put into a 30ml inner liner made of polytetrafluoroethylene, and the outer shell is made of steel;

[0046] (3) After sealing the reaction kettle, place it in an oven at 180°C for 10 hours, cool naturally, and centrifuge to obtain the product, wash the product three times with distilled water and absolute ethanol, and dry to obtain carbon nanospheres;

[0047] (4) Get above-mentioned carbon nanosphere 0.5 gram, be dispersed in the methanol of 20ml, add 2g zinc chloride successively, 0.05g ferric nitrate and 4g urea, obtain the alcoholic solution containing carbon sphere after ultrasonic dispersion;

[0048] (5) reacting the above prepared alcohol solution containing carbon sphe...

Embodiment 3

[0057] A kind of preparation ZnO / ZnFe 2 o 4 The method for composite nano hollow spheres, the steps are:

[0058] (1) Disperse 0.72 g of β-cyclodextrin in 24 ml of water, stir and dissolve to form an aqueous solution of carbohydrate compounds;

[0059] (2) The prepared saccharide compound aqueous solution is put into a 30ml inner liner made of polytetrafluoroethylene, and the outer shell is made of steel;

[0060] (3) After sealing the reaction kettle, place it in an oven at 200°C for 4 hours, cool naturally, and centrifuge to obtain the product, wash the product three times with distilled water and absolute ethanol, and dry to obtain carbon nanospheres;

[0061] (4) Take 0.1 g of the above-mentioned carbon nanospheres, disperse them in 20 ml of methanol, add 1 g of zinc nitrate, 0.1 g of ferric acetate and 1 g of ammonia water in turn, and obtain an alcoholic solution containing carbon spheres after ultrasonic dispersion;

[0062] (5) reacting the alcohol solution containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com