ZnFe2O4/C composite cathode material with hollow sphere structure and one-step preparation method thereof

A negative electrode material, znfe2o4 technology, which is applied in the field of hollow spherical structure iron-based composite oxide negative electrode material ZnFe2O4/C and its preparation, can solve the problems of few related reports and the like, and achieves simple process, uniform morphology and high crystallinity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

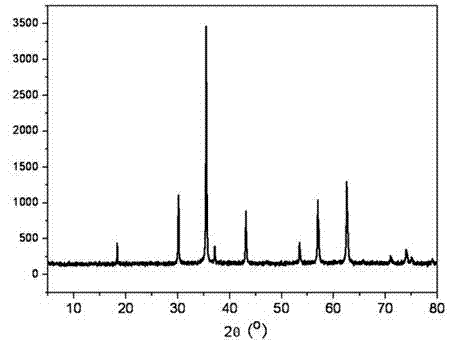

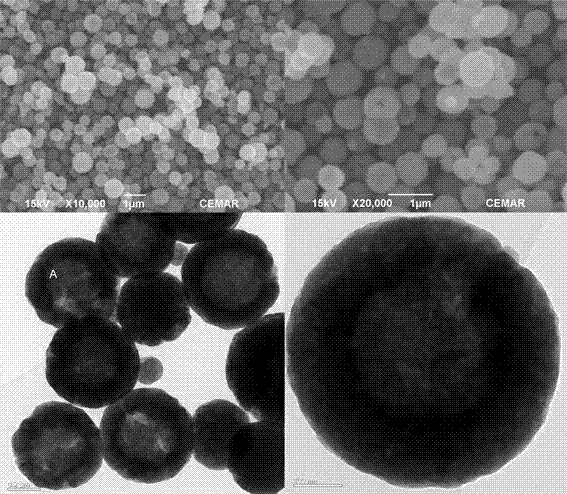

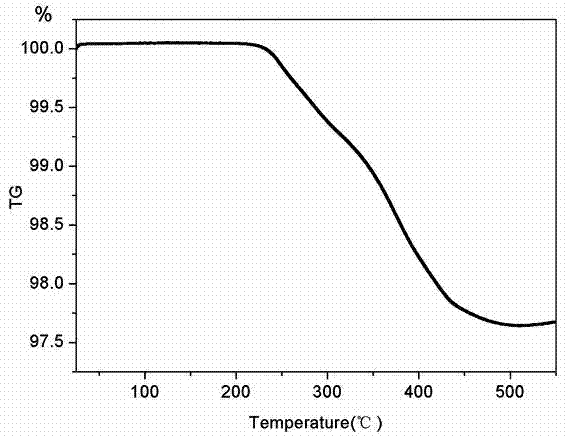

[0033] Weigh 0.34 g of zinc chloride and 1.35 g of ferric chloride hexahydrate respectively, dissolve them in 30 mL of ethylene glycol solution, then add 1 to 2 mL of polyethylene glycol 600 dropwise, at 30 o 2.73 g of urea and 1.0 g of glucose were slowly added under magnetic stirring at room temperature, and the stirring was continued for 1 hour at this temperature. The mixed solution was transferred to a 50 mL polytetrafluoroethylene-lined reactor and reacted at 200°C for 48 hours. After the reactor was cooled to room temperature, the supernatant was recovered for the next use. The obtained precipitate was separated by filtration, washed three times with deionized water and absolute ethanol, and dried in vacuum at 80°C for 12 hours to obtain a black product. The obtained product was subjected to EDS, thermogravimetric analysis, elemental analysis and XRD analysis respectively, indicating that the product was a hollow spherical structure ZnFe 2 o 4 / C, carbon content 2.30 ...

Embodiment 2

[0036] Weigh 0.34 g of zinc chloride and 1.35 g of ferric chloride hexahydrate respectively, dissolve them in 30 mL of ethylene glycol solution, then add 1 to 2 mL of polyethylene glycol 600 dropwise, and heat in a water bath at 40°C with magnetic stirring Slowly add 2.73 g of urea and 1.1 g of glucose, and keep stirring for 1 hour at this temperature. The mixed solution was transferred to a 50 mL polytetrafluoroethylene-lined reactor and reacted at 200 °C for 24 hours. After the reaction kettle was cooled to room temperature, the supernatant was recovered for the next use. The resulting precipitate was separated by filtration, washed three times with deionized water and absolute ethanol, and vacuum-dried at 80 °C for 12 hours to obtain a black product. The obtained product was subjected to EDS, thermogravimetric analysis, elemental analysis and XRD analysis respectively, indicating that the product was a hollow spherical structure ZnFe 2 o 4 / C, carbon content 2.38 wt%.

...

Embodiment 3

[0039] Weigh 0.68 g of zinc chloride and 2.70 g of ferric chloride hexahydrate respectively, dissolve them in 30 mL of ethylene glycol solution, then add 1-2 mL of polyethylene glycol 600 dropwise, and heat in a water bath at 40°C with magnetic stirring Slowly add 6.67 grams of urea and 1.2 grams of sucrose, maintain this temperature and continue stirring for 1 hour. The mixed solution was transferred to a 50 mL polytetrafluoroethylene-lined reactor and reacted at 200°C for 48 hours. After the reaction kettle was cooled to room temperature, the supernatant was recovered for the next use. The resulting precipitate was separated by filtration, washed three times with deionized water and absolute ethanol, and vacuum-dried at 80°C for 12 hours to obtain a black product. The obtained product was subjected to EDS, thermogravimetric analysis, elemental analysis and XRD analysis respectively, indicating that the product was a hollow spherical structure ZnFe 2 o 4 / C, carbon content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com