Low heat conductance silicon rubber foam material and manufacture method thereof

A foam material, low thermal conductivity technology, applied in the field of material technology, can solve the problems of large foam compression deformation, poor compression resistance, poor product dimensional stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

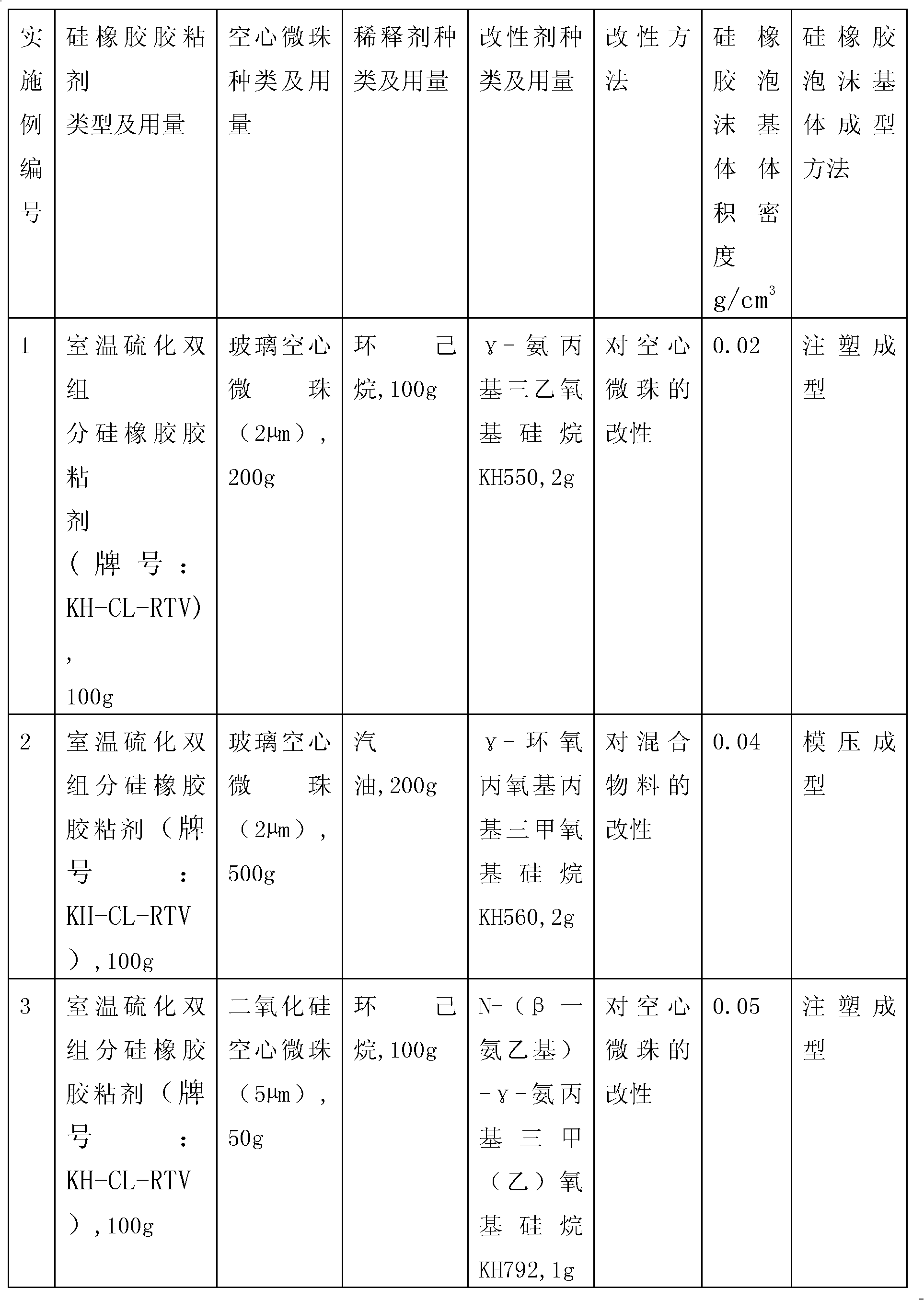

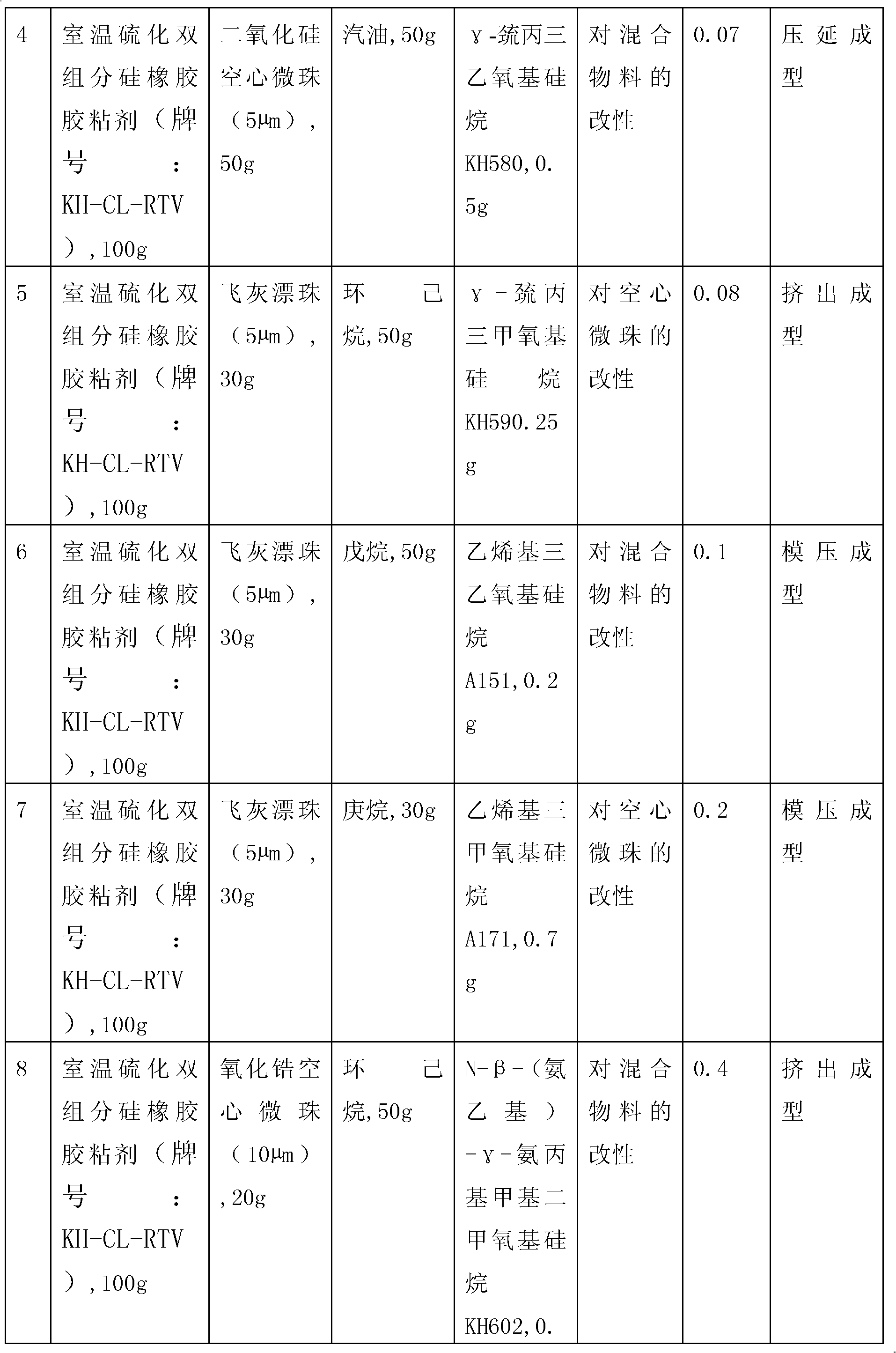

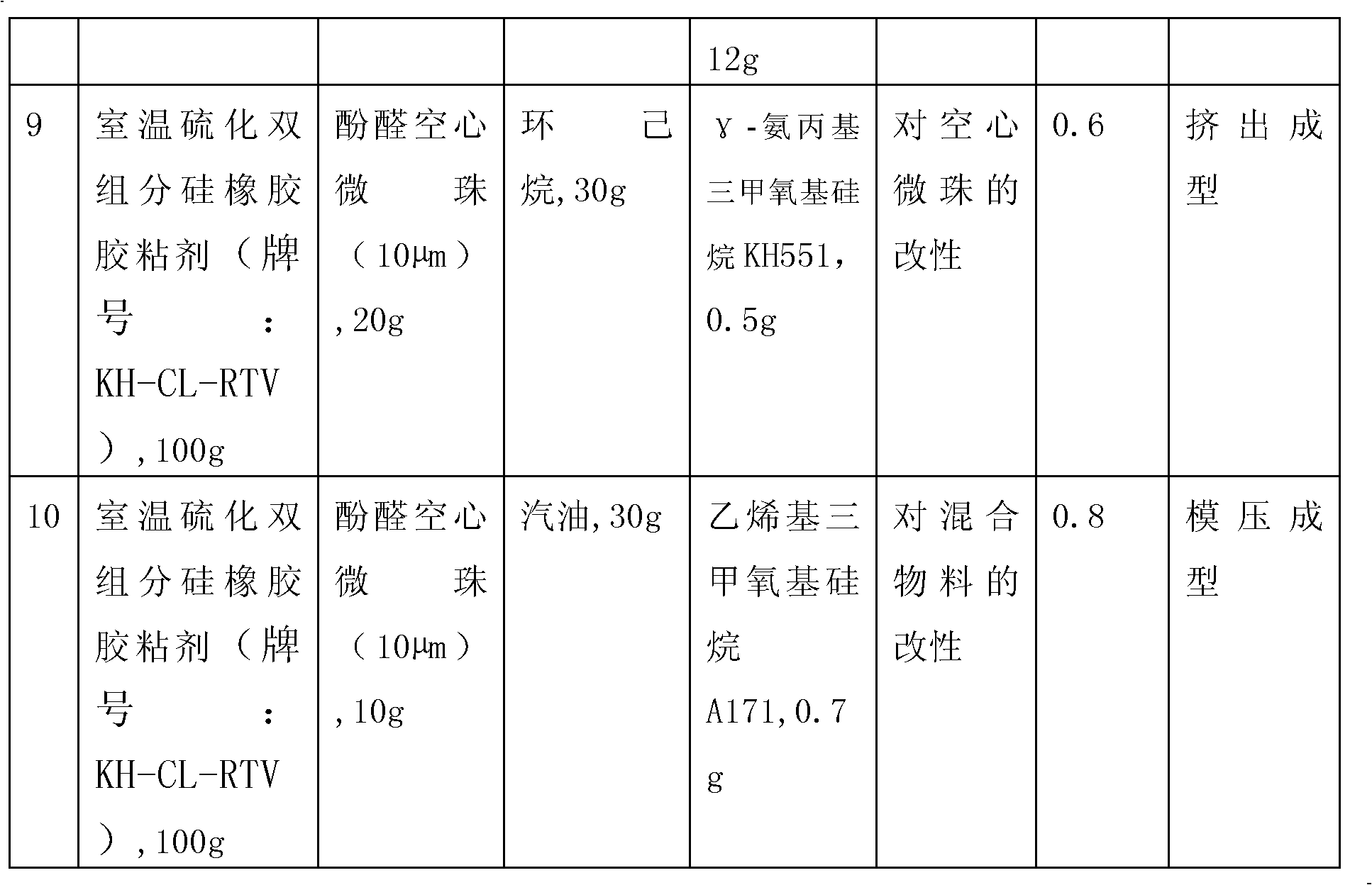

Examples

Embodiment 1

[0052] Add 100g of cyclohexane as a diluent and 0.2g of silane coupling agent γ-aminopropyltriethoxysilane KH550 as a modifier into the container, and mix well. Then add 100 g of room temperature vulcanizing two-component silicone rubber adhesive (brand: KH-CL-RTV) into the container and mix well. Finally, 100 g of glass hollow microspheres with a diameter of 2 μm were added and stirred until all the glass hollow microspheres were covered by the silicone rubber adhesive.

[0053] Spread the mixed material into the mold cavity according to the shape of the product, press molding by molding, and cure for 48 hours at room temperature. The density of the fully cured silicone rubber foam matrix is 0.1g / cm 3 .

[0054] Add tetraethyl orthosilicate as reaction raw material, ethanol as alcohol solvent, deionized water and ammonia water, respectively: 2080g, 7300g, 540g, 14g, and mix uniformly to form a sol.

[0055] The silicon rubber foam matrix is put into a vacuum impregnati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com