Hydration heat inhibited concrete expanding material as well as preparation method and applications thereof

A technology of hydration heat suppression and expansion material, which is used in drying shrinkage, hydration heat suppression type concrete expansion material and its preparation, and the application field of temperature shrinkage performance, which can solve the problem of increased slump loss and water absorption of fluidized concrete. The problems of large reduction in multiples and low early strength can achieve the effects of increasing temperature shrinkage stress, reducing temperature shrinkage cracks, and improving adiabatic expansion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

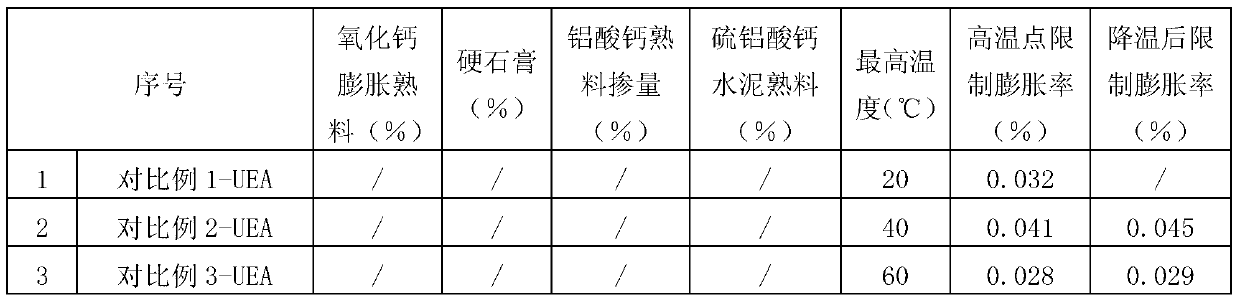

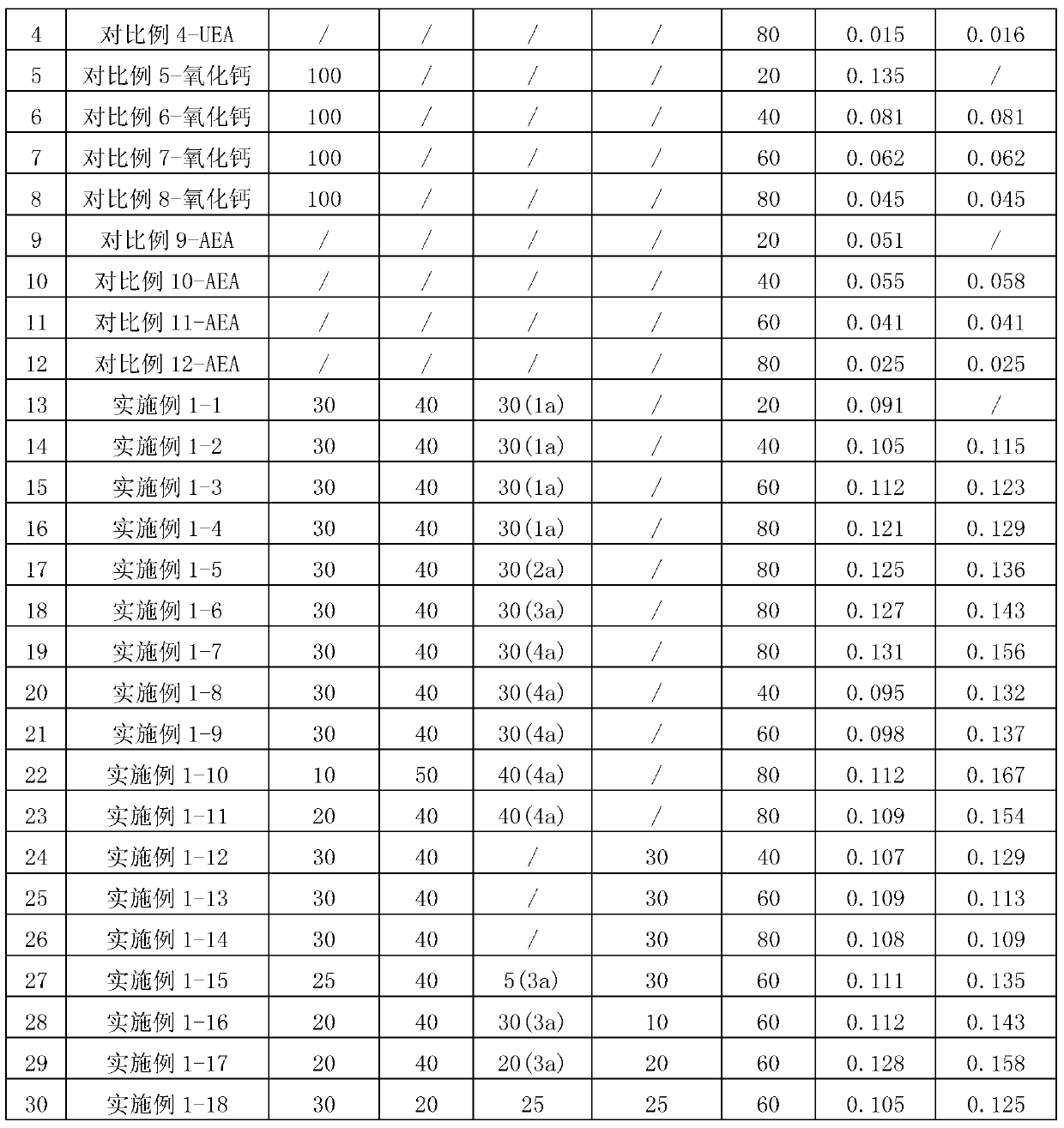

Examples

Embodiment 1

[0109] Embodiment 1, preparation with CA 2 Calcium aluminate clinker as the main mineral and its application in the preparation of expansion agent

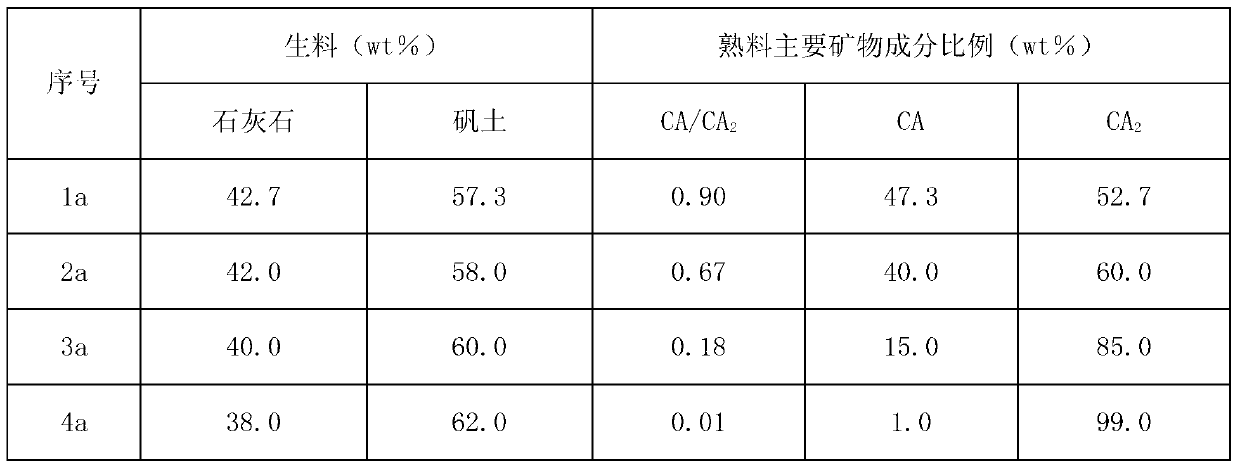

[0110] 1. First prepare the calcium dialuminate (CaO·2Al 2 o 3 , abbreviated as CA 2 ) as the main mineral calcium aluminate clinker, using Al 2 o 3 Content 74.5%, SiO 2 Bauxite with a content of 8.2% ( ) and CaO content of 55.5% (≥55%), SiO 2 Limestone with a content of 0.2%, prepare the raw meal according to the ratio shown in Table 1, use a ball mill to grind the raw meal, and control the fineness of the raw meal to 450m 2 / kg, using an electric furnace or a rotary kiln to calcinate calcium aluminate clinker, the calcining temperature is 1550°C-1650°C, and the calcining time is 60-120min to obtain calcium aluminate clinker. The main mineral composition ratio of calcium aluminate clinker is shown in Table 1:

[0111] Table 1 The proportion of main mineral components of calcium aluminate clinker

[0112]

[0113] 2...

Embodiment 2

[0123] Example 2. Preparation of Heat of Hydration Inhibitor and Performance Testing

[0124] The heat of hydration inhibitor is prepared by using commercially available cornstarch and wheatstarch as raw materials through dry heat reaction. Firstly, according to the ratio of corn starch and wheat starch in Examples 2-1 to 2-24 shown in Table 3, the ingredients were prepared, and then the starch was subjected to hydrochloric acid catalytic pretreatment (hydrochloric acid mass concentration 12.5%, dosage 0.1wt%), Drying, control the moisture content of the starch at 1-5%, and then heat-convert the dried starch, strictly control the heating temperature (110-130°C), the heating uniformity of the starch and the reaction time (8-10 hours), During the heating process, continuous and uniform stirring is carried out, the reaction product is cooled, and sieved to obtain the heat of hydration inhibitor. The heat of hydration inhibitor samples were tested for cold water solubility and re...

Embodiment 3

[0136] Embodiment three, performance detection of internal curing agent

[0137] The internal curing agent of the present invention adopts commercially available polyacrylate cross-linked resin (SAP, purchased from Beijing Huaruixiang Technology Co., Ltd.), with a particle size of 100-120 mesh, a water absorption rate of 400mL / g, and a salt water (NaCl aqueous solution with a concentration of 0.9%) ) rate ≥ 30mL / g.

[0138] The concrete mix ratio used in the test is as follows: PO42.5MPa cement: 430kg / m 3 ; Expansion material: 50kg / m 3 ;Water: 235kg / m 3 ;Sand (fineness modulus 2.6): 700kg / m 3 ;Stone (particle size 5-20mm): 985kg / m 3 .

[0139] In the test, the expansion material includes expansion agent and heat of hydration inhibitor, and the product of the embodiment of the present invention is used to grind together to a specific surface area of 300m 2 / kg; Also add internal curing agent SAP according to Table 5.

[0140] There are two kinds of SAP mixing methods: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com