Hollow profile decking system comprising plank and anchor using anchor flange construction

a hollow profile and anchoring technology, applied in the field of platform or decking, can solve the problems of increasing cost of wood products, plywood and chipboard materials, substantial structural and thermal drawbacks, etc., and achieve the effect of reliable support and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

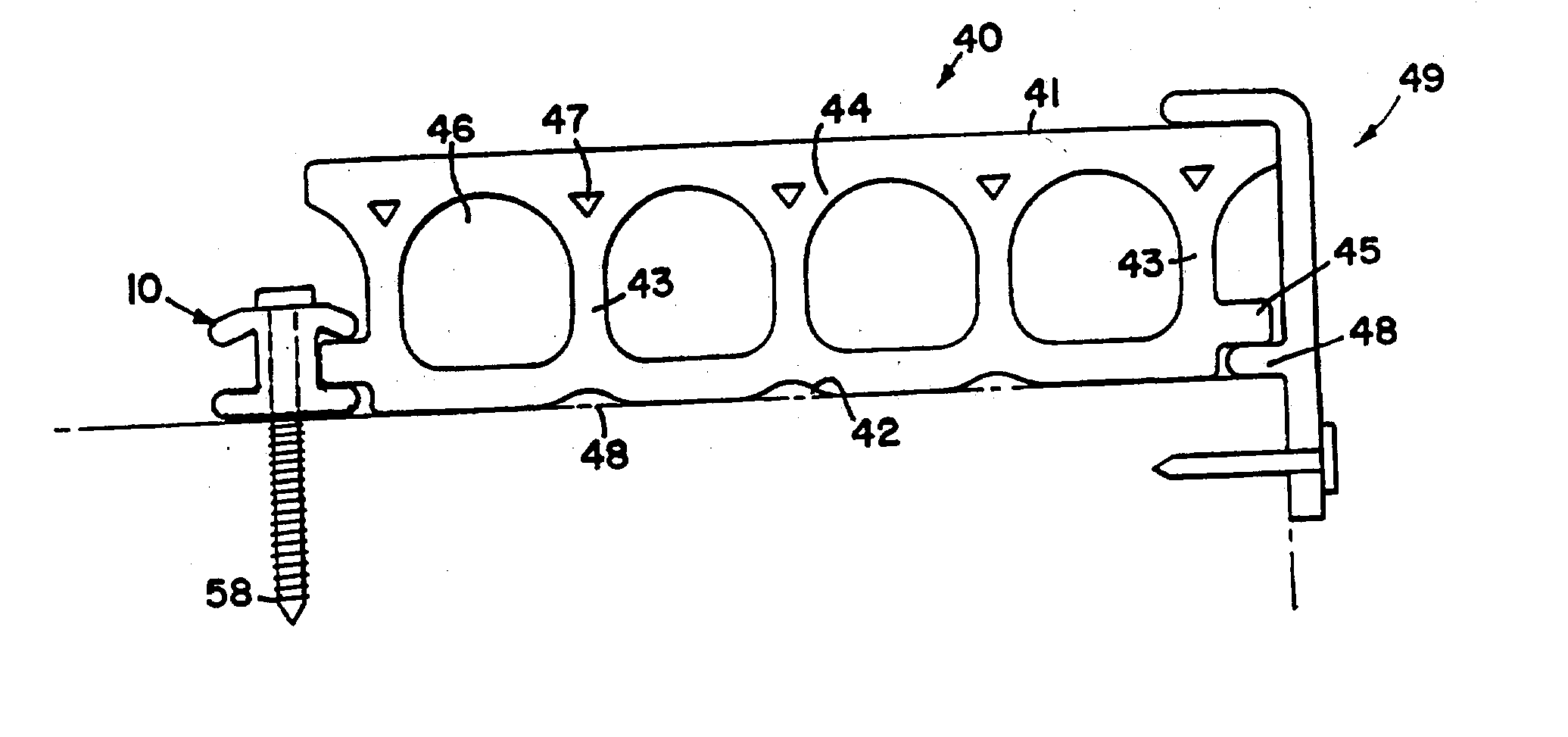

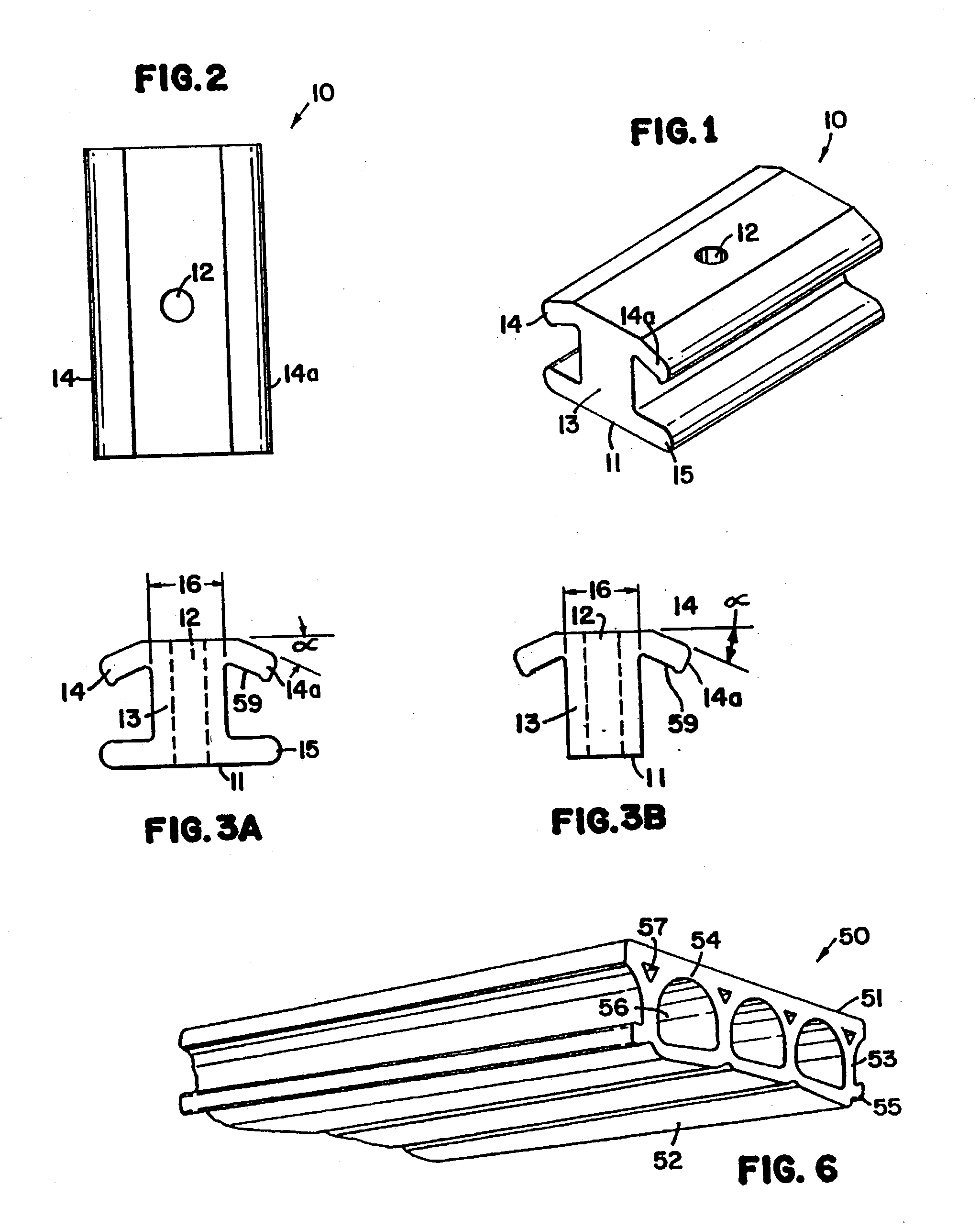

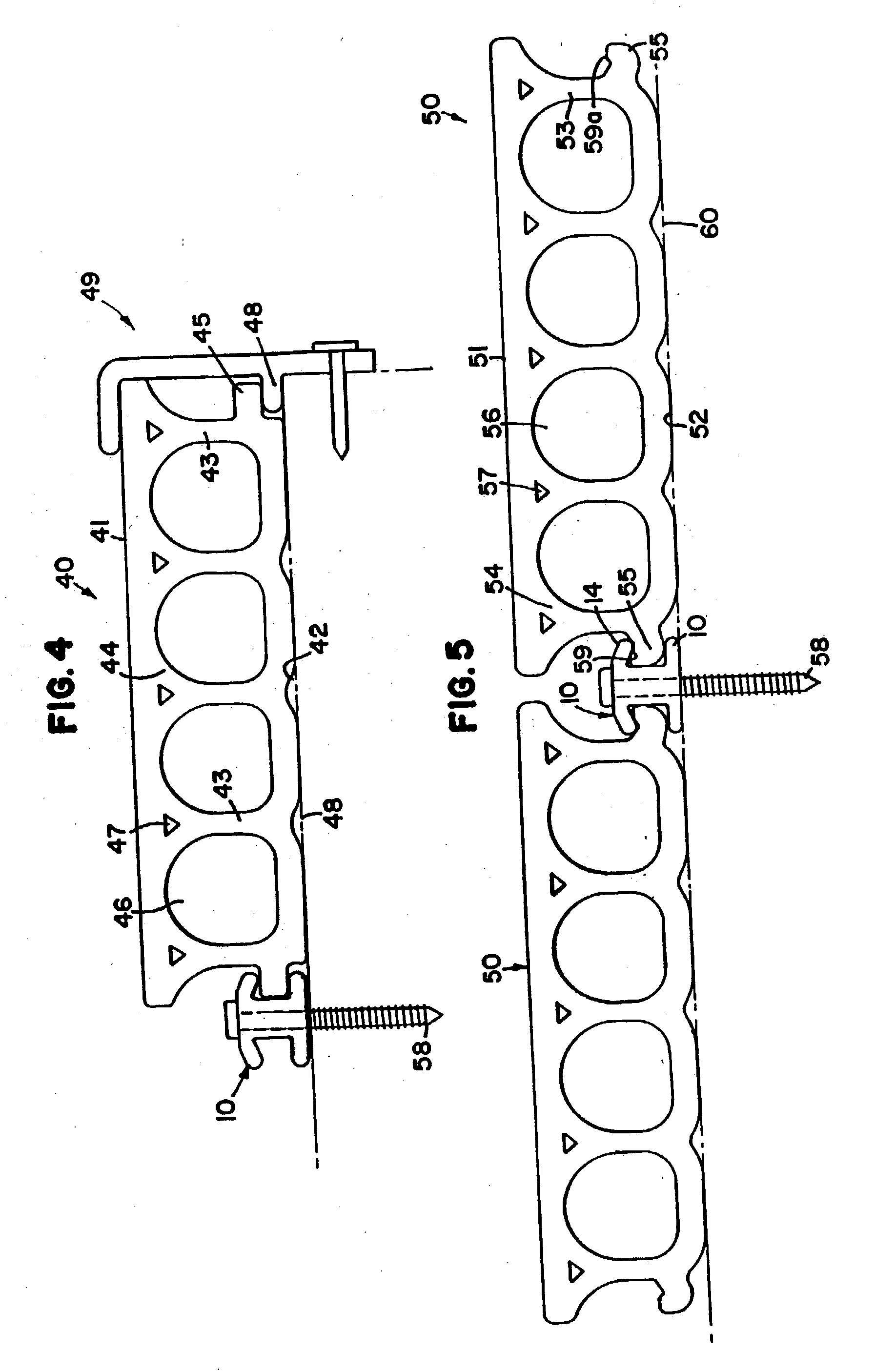

[0017] FIGS. 1, 10, and 13 show isometric views of the anchor structure of the invention. Referring now to FIG. 1, the anchor structure 10 is installed by placing the anchor structure on a support surface. The anchor structure is placed on the base 11 interacting with the installation surface (not shown). The anchor structure is then installed or fixed in place by inserting fastener hardware through aperture 12. Anchor structure 10 comprises a base portion having base 11 and an extended transverse base flange 15 forming a support area with a large surface area to ensure stable installation. The anchor structure 10 has a vertical member or portion 13 supporting a transverse portion comprising an anchor flange 14 and a second anchor flange 14a. These anchor flanges 14 and 14a interact with the plank anchor flange (not shown, see FIGS. 4, 5, and 6) of a plank or of a second, adjacent deck plank.

[0018] FIG. 2 is a top view of the anchor structure 10 of FIG. 1. In the center of the ancho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com