Large double-curve steel structure cooling tower for power plant

A technology for cooling towers and steel structures, applied in towers, refrigeration plants, building types, etc., to achieve the effects of simple handling, reduced structural weight, and low maintenance costs in the later period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

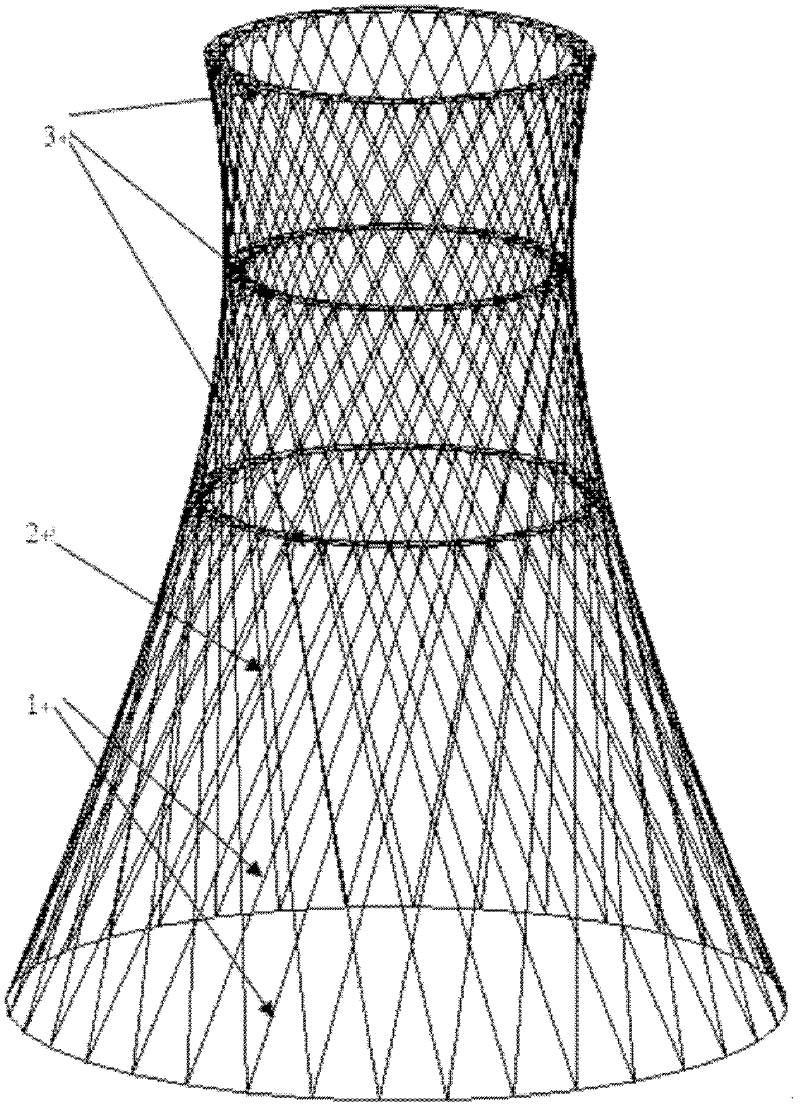

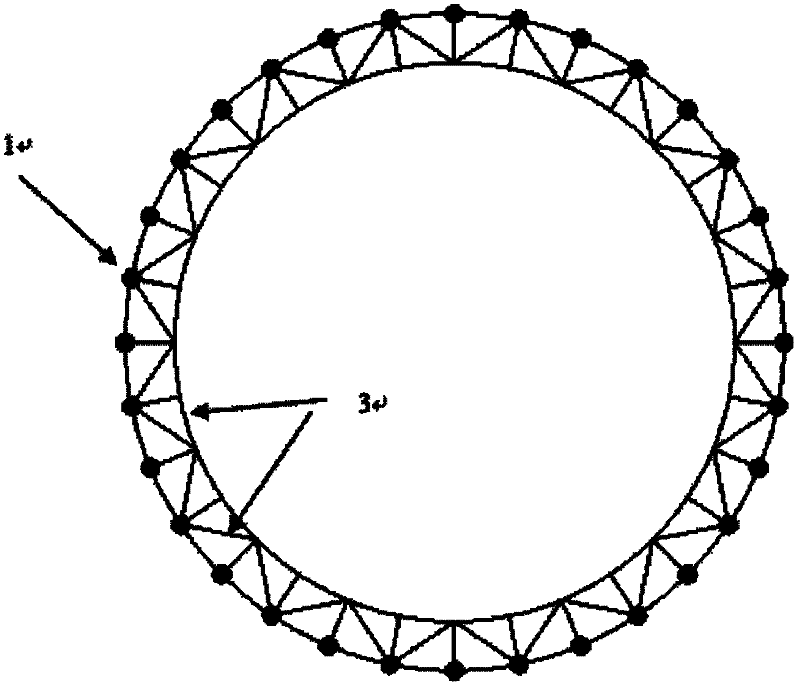

[0020] see figure 1 , 2 , 3 and 4, a hyperbolic steel structure cooling tower, including straight-line inclined columns, intersecting nodes and stiffening rings, the vertical line rotation array formed by the straight-line inclined columns around the center of the tower and the center of the lower circle constitutes the skeleton of the hyperbolic cooling tower , the intersections of straight and oblique columns are nodes, and along the height direction of the tower, three to five stiffening rings are arranged as required. The height of the tower exceeds 150m, and the diameter of the lower part is about 150m.

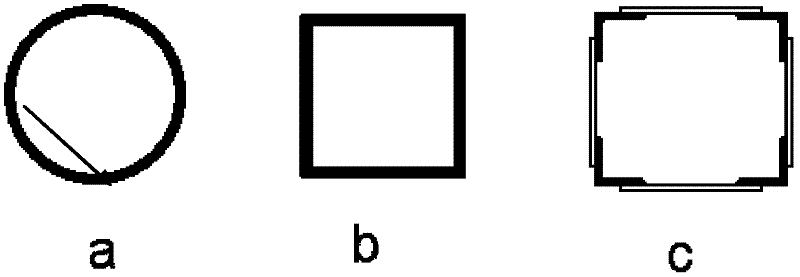

[0021] The straight-line oblique column is a round steel column or a square steel column with a cross-sectional diameter or side length between 500mm and 1000mm; it can also be a square lattice column made of angle steel or channel ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com