Protective helmet and method of manufacture thereof

a protective helmet and helmet technology, applied in the field of protective helmets, can solve the problems of insufficient rigidity of the shell to provide the protection expected from the finished helmet, inconvenient positioning of the device in the helmet made using the in-molding technique, and insufficient aesthetics. to achieve the effect of improving appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

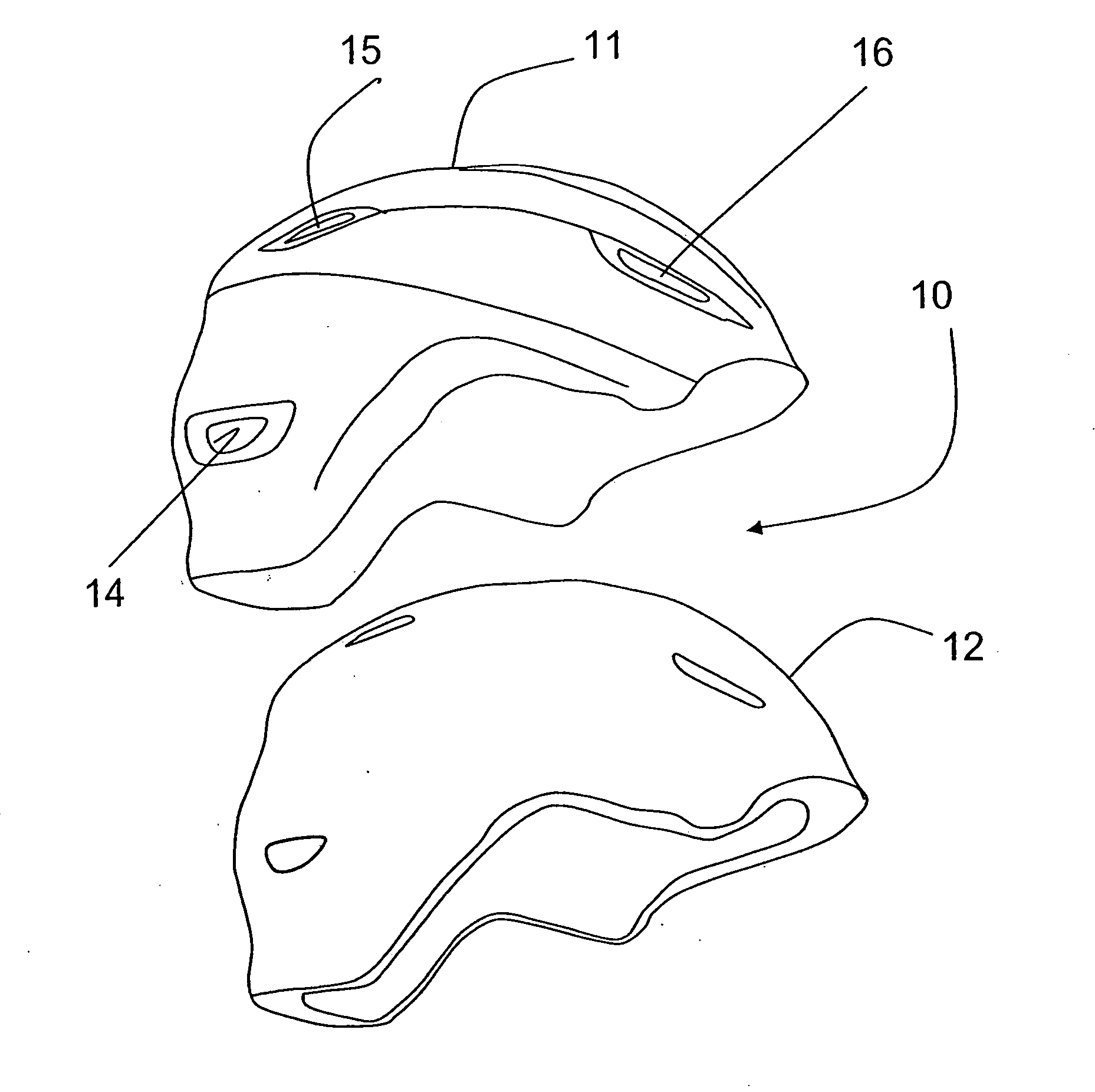

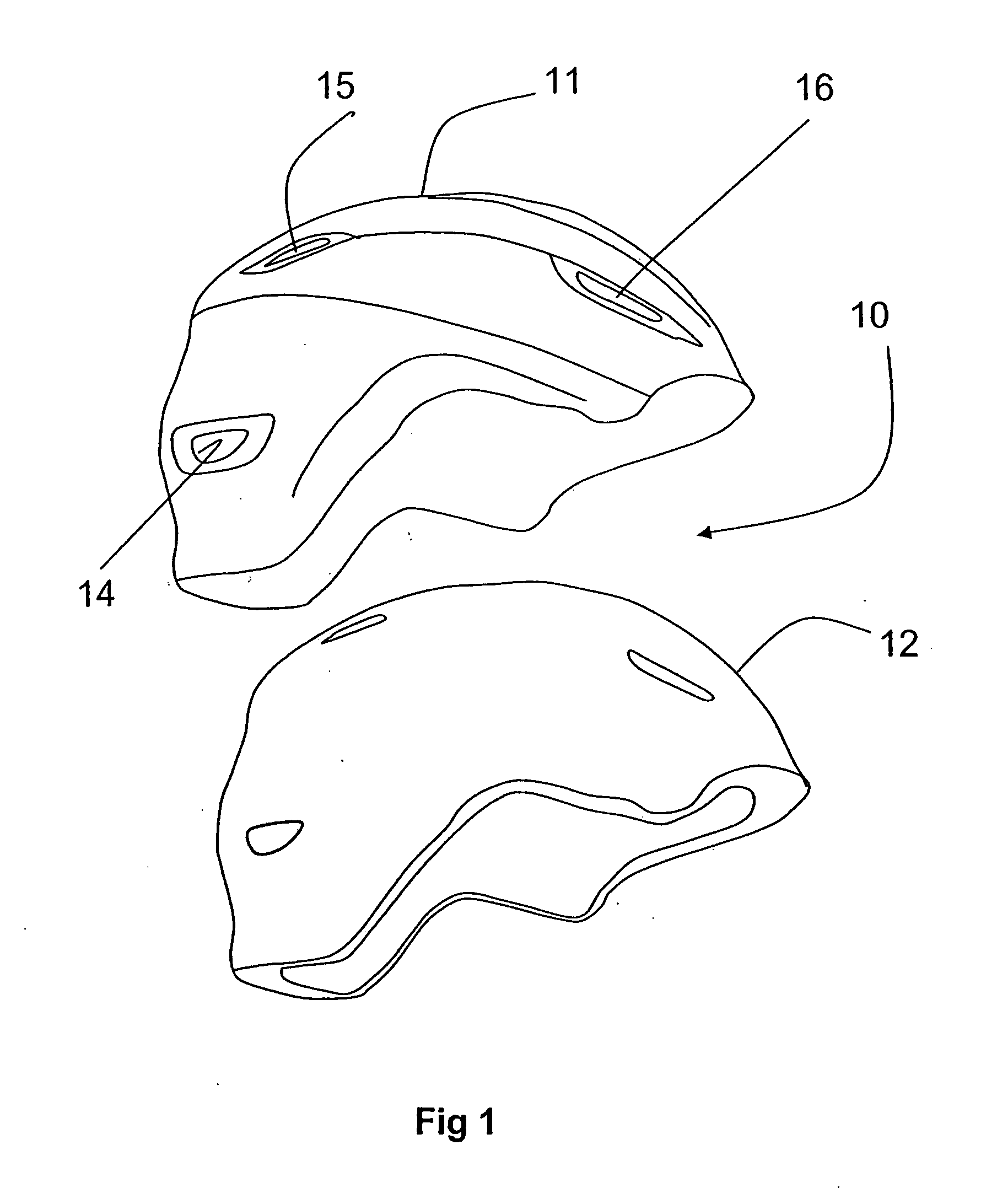

[0043]FIG. 1 shows a helmet 10 including an outer shell 11 and an inner cap 12.

[0044] The outer shell is formed by a shell of plastic material, the shell being thin, having a thickness of 1.5 millimeters (mm), or a thickness of about 1.5 mm or less than about 1.5 mm. In particular, the shell can be produced from a flat sheet of polycarbonate or of PVC having a thickness between 0.7 mm and 1.5 mm, or between about 0.7 mm and about 1.5 mm, that has been cut and shaped by thermoforming. The shell can, optionally, have openings, such as the openings 14, 15, 16, and other openings, if necessary or desired, as well as recessed or raised zones, possibly with form-breaking edges, which may or may not correspond to the openings.

[0045] The inner cap 12 forms a shock-absorbing layer provided to envelop and protect the user's head. It can be made of expanded polystyrene, for example. It is provided to line the outer shell 11 internally. The outer surface of the cap assumes the inner shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com