Hub strength calculation method of wind power generating unit

A technology for wind turbines and strength calculation, which is applied in the fields of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of large calculation workload, no simplified geometric model for explanation, no introduction of wheel hub fatigue life, etc. The effect of improving accuracy, accurate force transmission and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

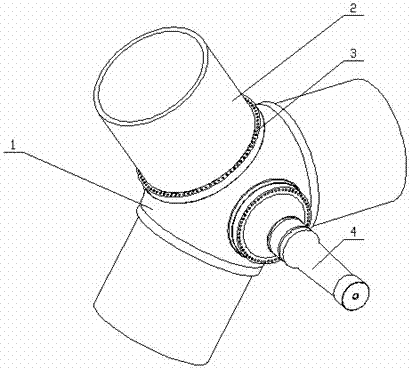

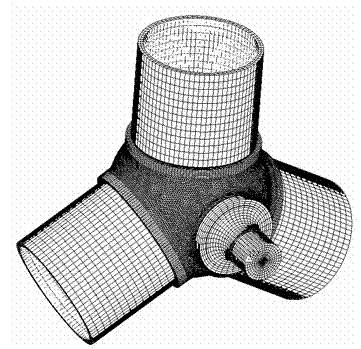

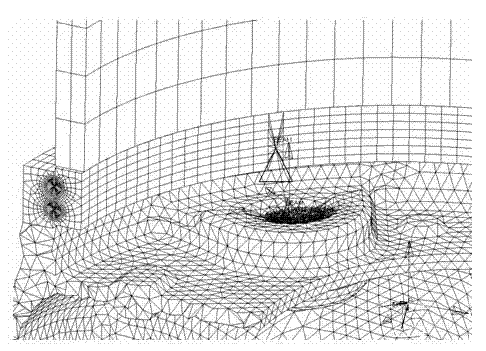

[0027] A method for calculating the hub strength of a wind power generating set uses 3D software to establish a geometric model. Before modeling, it is necessary to have an overall understanding of the external interface parts and forces of the hub. The main components connected with the hub 1 are the variable pitch bearing 3, the variable pitch drive, the blade 2, the wedge disc and the main shaft 4. In the process of establishing the geometric model, it is necessary to simplify the features that have little influence on the strength, such as small chamfers and bosses. The established geometric model is as figure 1 shown. After converting the geometric model into an intermediate format file, import it into professional finite element pre-processing software, mesh the model and define material properties for related parts, so as to establish the finite element model required for analysis, and the established finite element model such as figure 2 with image 3 shown. In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com