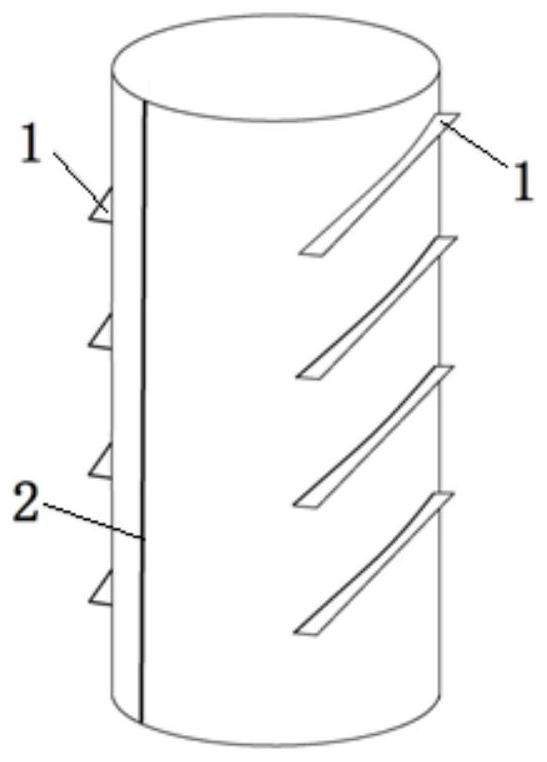

Device and method for accurately positioning reinforcing steel bars

A fingerprint device and precise positioning technology, which is applied to buildings, building reinforcements, building components, etc., can solve the problems of large position error of steel bars, inefficient construction of concrete structures for durability of concrete structures, and large thickness deviations of steel protective layers. Guaranteed quality, simple and convenient connection method, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

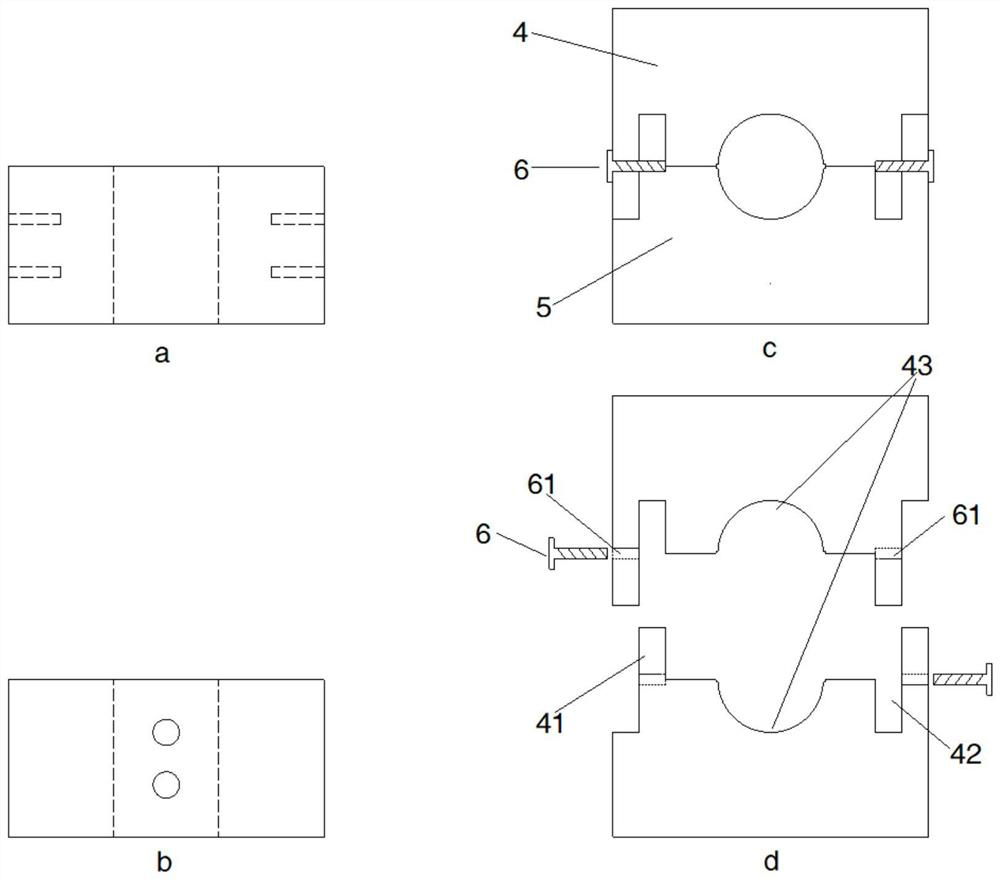

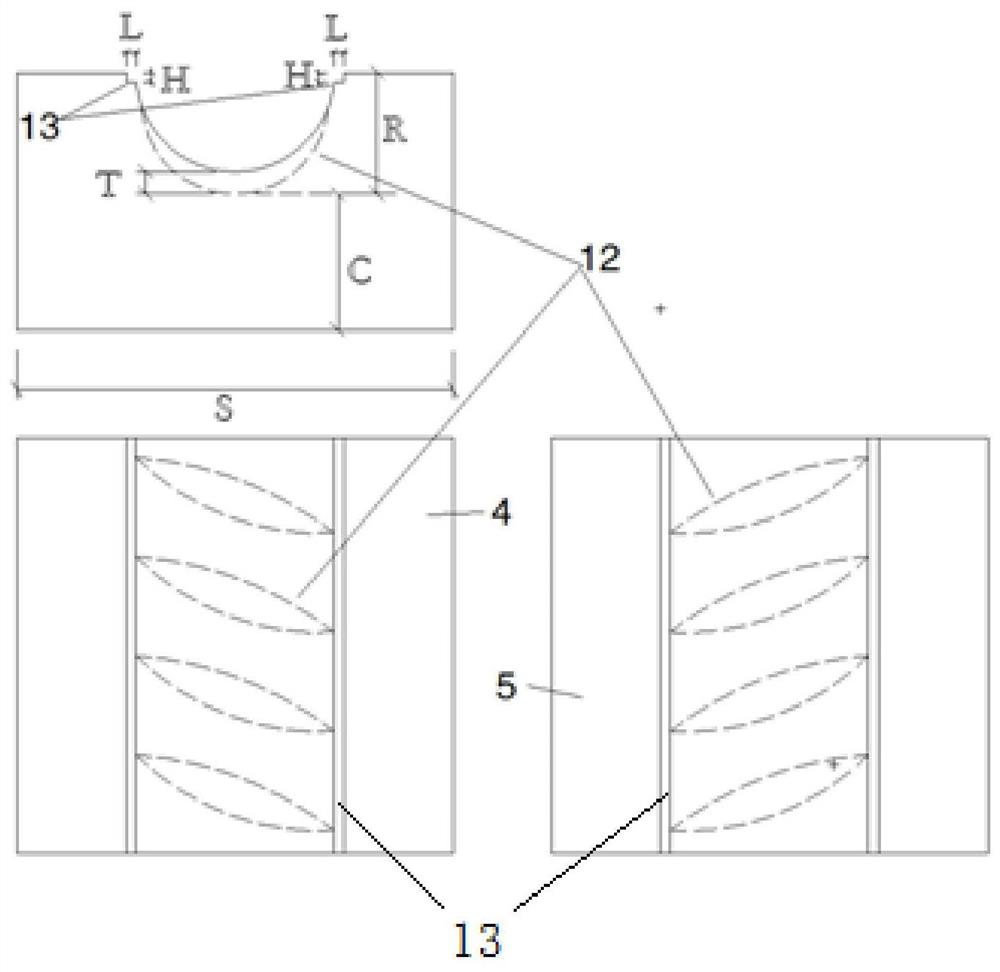

[0031] The prefabricated concrete beam will be described as an example below. The size of the snap-fit fingerprint module set on the prefabricated beam is 80mm*80mm*40mm. image 3From the point of view, the number of horizontal ribs and female ribs set in the groove of the fingerprint module is determined according to the specifications of the fingerprint module and the steel bar, generally not less than two. The width S of the fingerprint module should not be less than twice the diameter R of the steel bar, and the thickness C of the protective layer of the steel bar at the edge of the component must meet the requirements of the specification. The female longitudinal rib pattern is a square groove surface with a height of H and a width of L. When the fingerprint module is fastened, the longitudinal female rib pattern and the longitudinal rib of the steel bar are tightly occluded. Its specification matches the longitudinal rib of the steel bar, H is half the height of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com