Multi-run automobile covering part mold trimming device

A technology for automobile covering parts and trimming devices, which is applied in the directions of vehicle parts, transportation and packaging, forming tools, etc., can solve the problems of low integration of covering parts and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

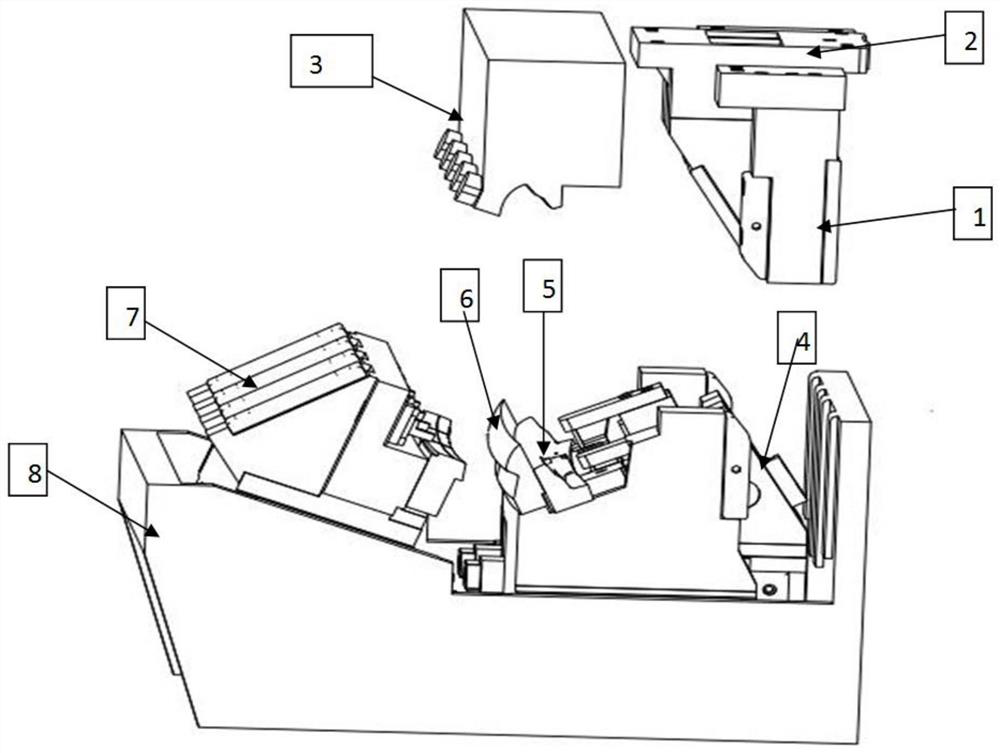

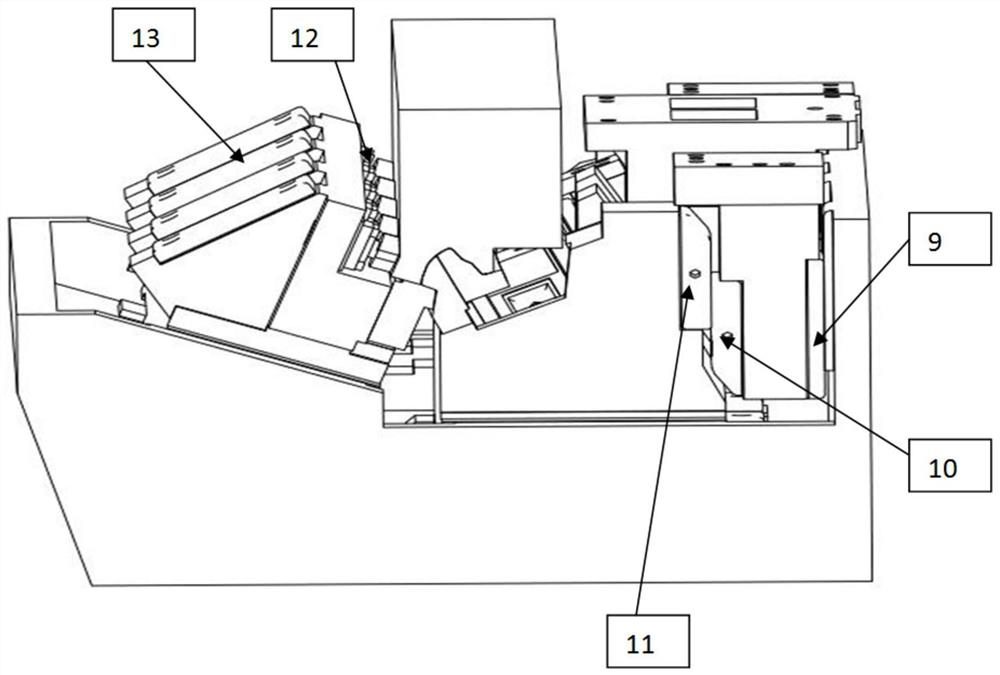

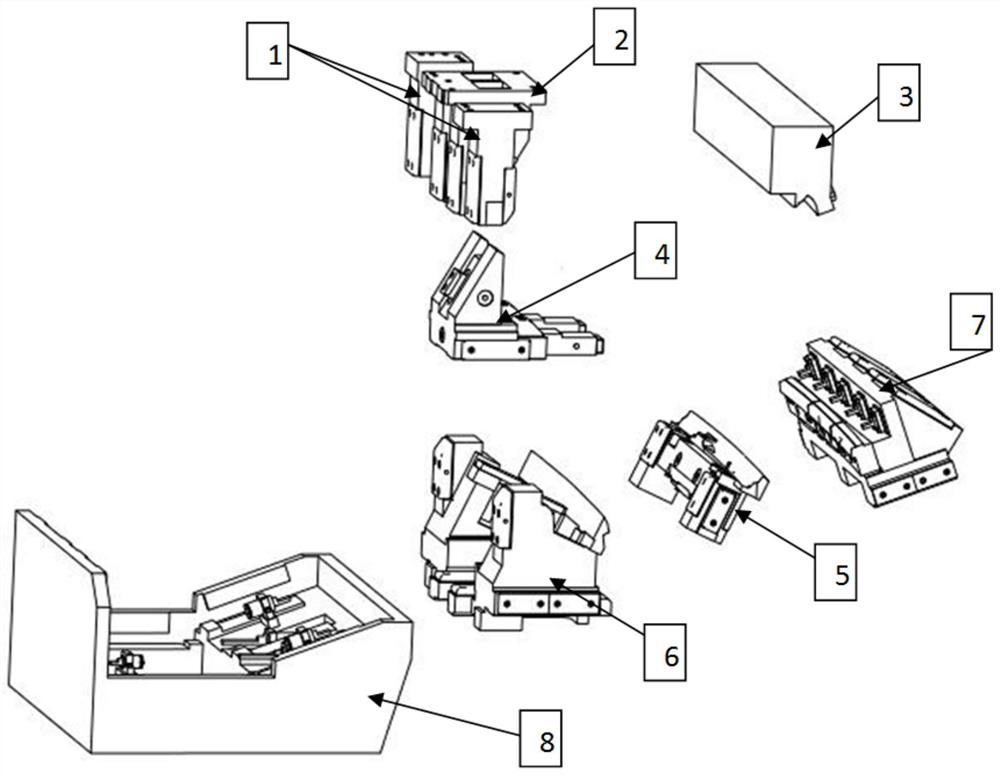

[0064] Embodiment 1, a kind of multi-travel automobile panel mold trimming device, such as Figure 1-20 As shown, it includes direct drive block 1, differential drive group 2, upper pressure block 3, balance lifting frame 4, tongue support block 5, blossom shaping block 6, reinforced side block 7, energy storage base 8, direct drive Guide plate 9, direct drive guide plate 10, shaping drive guide plate 11, reinforced spring 12, reinforced return guide plate 13, differential anti-side guide plate 14, differential drive guide plate 15, tongue push guide plate 16, balance limiter block 17, balance guide plate 18 , Tongue return spring 19, Lifting tongue guide plate 20, Sliding tongue guide plate X21, Sliding tongue Y22, Sliding tongue guide plate Z23, Tongue return pressing plate 24, Flowering guide plate 25, Tongue holding guide plate 26, Side straightening guide plate 27, Side block 28, Side Whole return spring 29, balance weight return spring 30, flowering return spring 31 and ...

Embodiment 2

[0075] Embodiment 2, a kind of multi-travel automobile panel mold trimming device, the working process of this device is as follows Figure 21 Shown:

[0076]①. The energy storage base 8 of this device is installed on the lower mold body of the mold, and the direct drive block 1, the differential drive group 2, and the upper pressing block 3 are installed on the upper mold body, such as figure 1 As shown in the general assembly drawing of the non-working state, put the parts to be processed, and then start to work. The lower die body does not move during work, and the upper die body drives the direct drive block 1, differential drive group 2, upper pressure block 3 and 7 to enhance side alignment The upper mold structure corresponding to block 7 moves downward rapidly.

[0077] ②, when the two symmetrical direct drive blocks 1 move downward, the direct drive guide plate 10 on the direct drive block 1 is a mold standard part and is a trapezoidal guide plate, pushing the shapin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com