Golf club head having a thin-type cover plate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

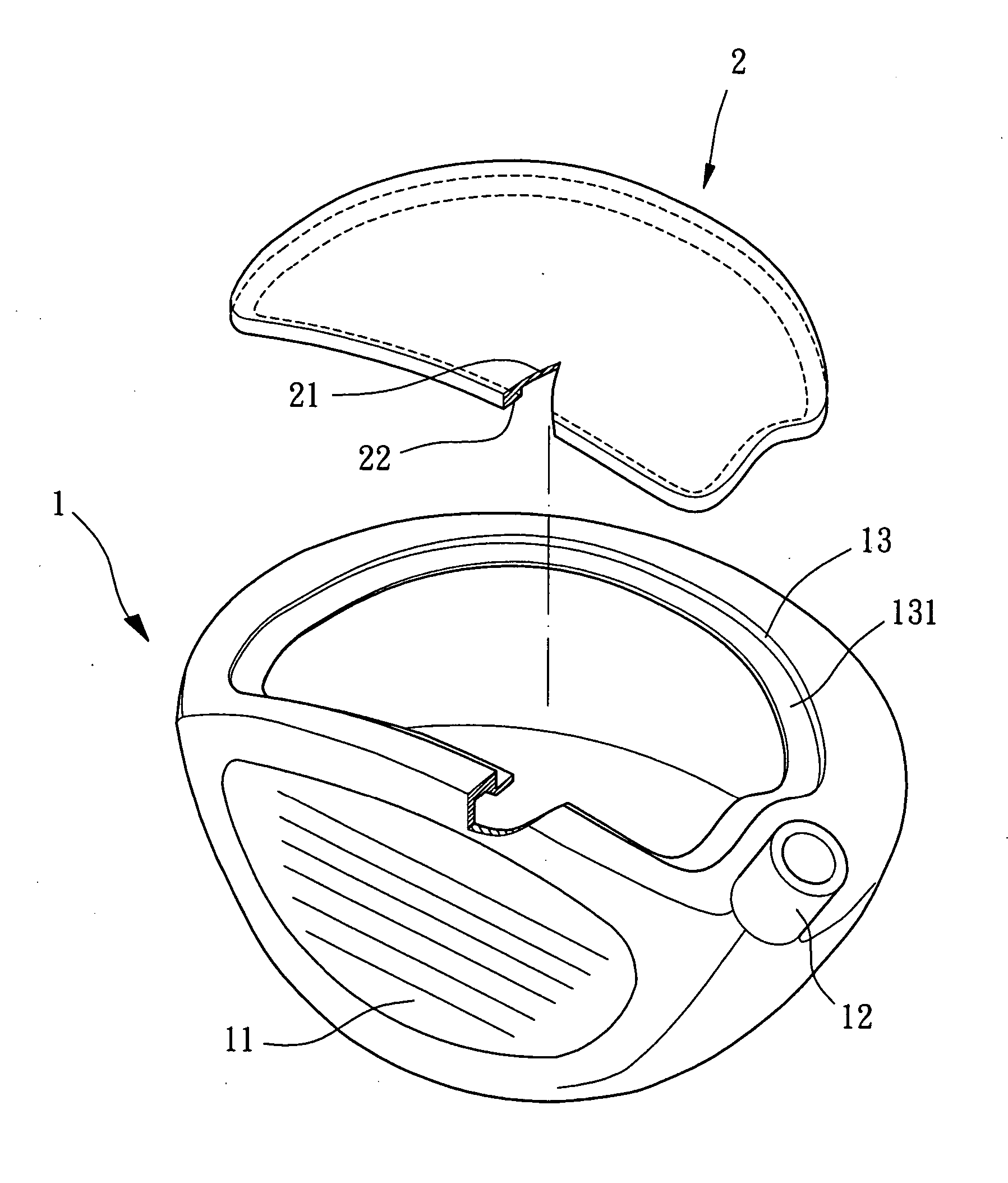

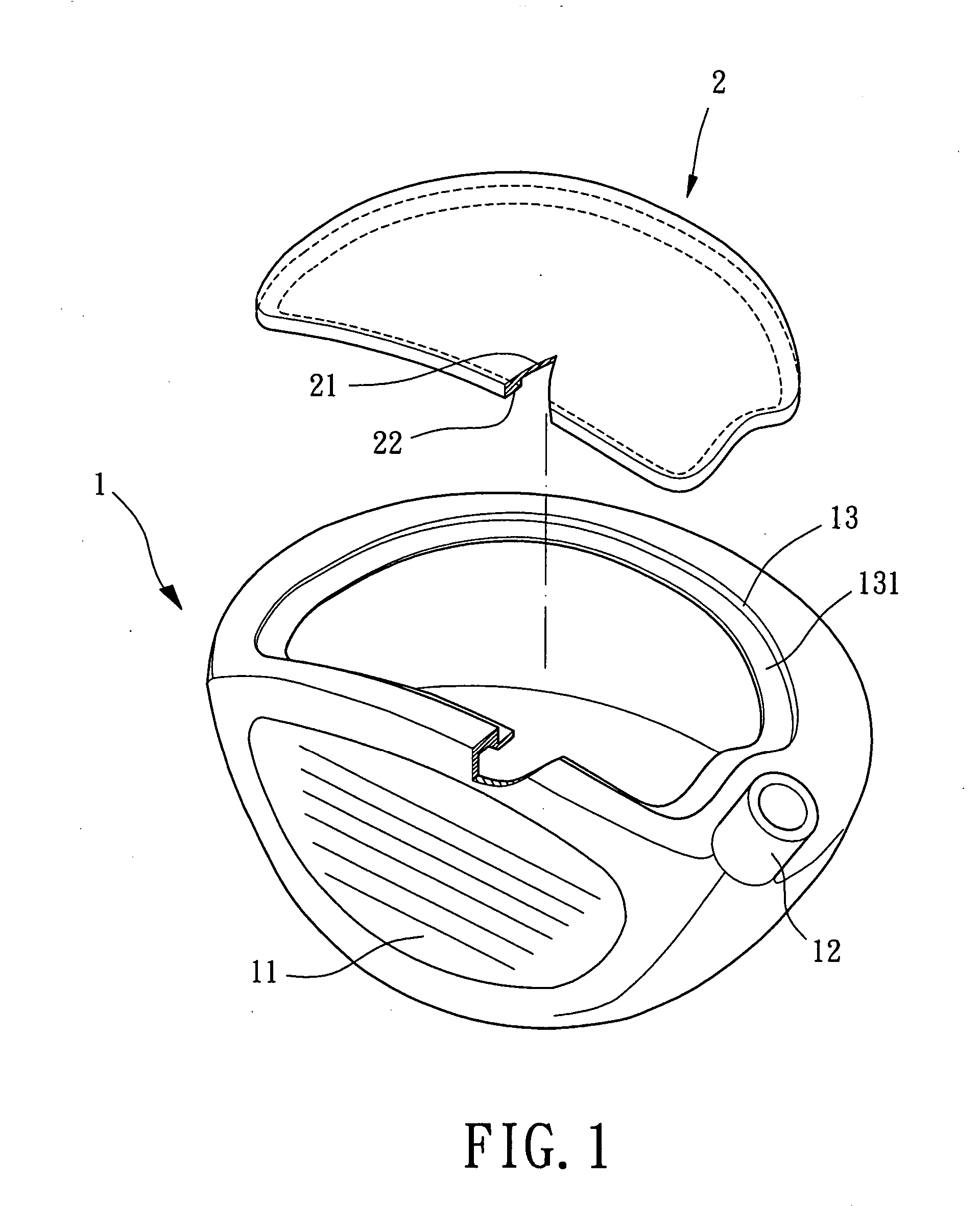

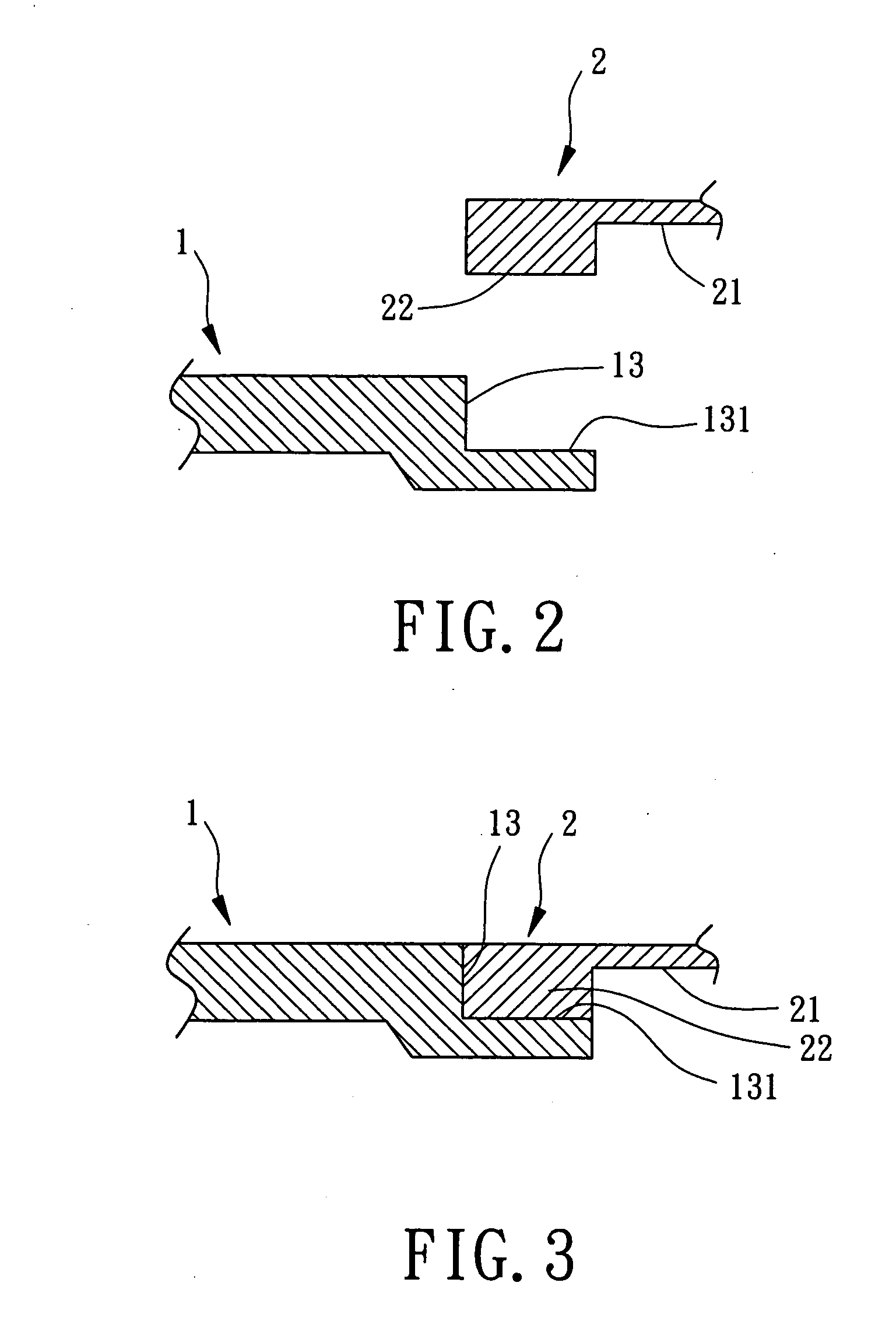

[0036] Referring again to FIGS. 1 and 2, the construction of the golf club head body 1 shall be described in detail. The golf club head body 1 is a monolithic body, and constructed from materials selected from a group consisting of metal, nonmetal and alloy. In particular, the golf club head body 1 so constructed from nonmetal can be formed either from similar or dissimilar materials. The golf club head body 1 includes a striking plate 11 and a hosel 12. Both of the striking plate 11 and the hosel 12 has a conventional configuration and is integrally formed on the golf club head body 1 or connected to the golf club head body 1 by welding, brazing, snap-connecting, screw-connecting, adhesion or some other fastening means. The golf club head body 1 further provides with an assembling opening 13 on a crown portion in place. In the illustrated first embodiment, the assembling opening 13 is integratedly formed on a crown portion of the golf club head body 1. The assembling opening 13 of ...

fourth embodiment

[0046] In the fourth embodiment, the stepped inner periphery 131′ of the assembling opening 13′ of the golf club head body 1 further provides with an annular groove 132′. Correspondingly, the reinforcing outer edge 22′ of the sole plate 2′ provides with an annular protrusion 221′ which serves to engage with the annular groove 132′ of the assembling opening 13′. In initially assembling, the annular protrusion 221′ of the reinforcing outer edge 22′ of the sole plate 2′ is engaged in the annular groove 132′ of the assembling opening 13′ of the golf club head body 1 so as to increase assembled reliability therebetween. Subsequently, the sole plate 2′ can selectively connect with the assembling opening 13′ of the golf club head body 1 by tungsten inert gas (TIG) welding, laser welding, plasma welding, electron beam welding, brazing, adhesion, snap-connecting or some other suitable fastening means.

[0047] In an alternative embodiment, it will be understood that the assembling hole of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com