Silicon dioxide mesoporous material and its preparing method

A technology of silica and mesoporous materials, applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of large diffusion resistance, unfavorable material transmission, and large internal diffusion resistance in one-dimensional pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

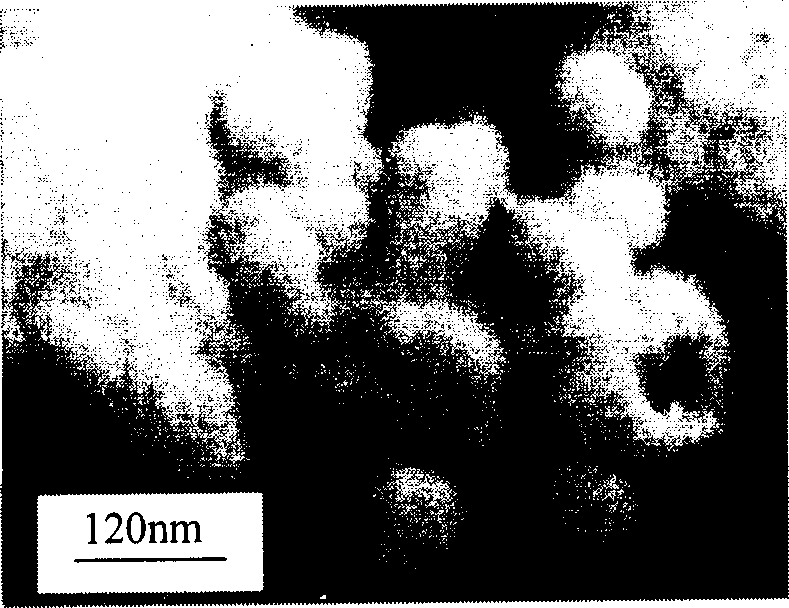

[0075] Embodiment 1 The preparation method of thin-shell nanometer mesoporous spheres

[0076] Take by weighing 40nm calcium carbonate powder (cubic) 8.7g, add deionized water 50g, add 2.5g cetyltrimethylammonium bromide (CTMAB) and 13.2g (about 15ml) analytical pure ammonia water, Then add 60g of ethanol, stir for 15min at a rotating speed of 300rpm, add tetraethyl orthosilicate (TEOS) according to silicon dioxide / calcium carbonate=0.15 (weight ratio), stir for 2 hours, filter and wash the filter cake with an appropriate amount of ethanol. Dry in an oven at a temperature of 90°C, and bake in a muffle furnace at a temperature of 550°C for 5 hours. Dissolve the sample with dilute hydrochloric acid, keep the pH below 1, and dry to obtain the product.

Embodiment 2

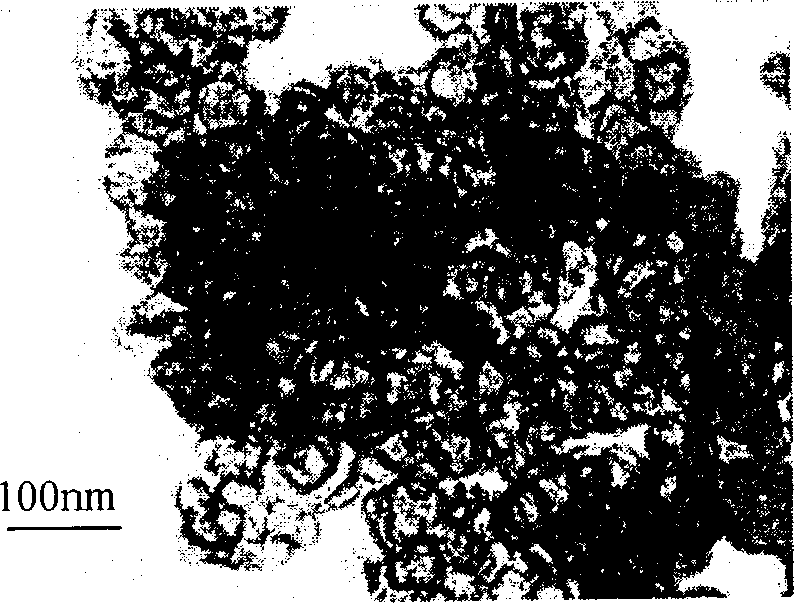

[0078] Preparation method of mesoporous hollow tube

[0079] Weigh 8.7g of calcium carbonate powder (needle) with a diameter of 200-300nm and an aspect ratio of 5, add 50g of deionized water, add 2.5g of cetyltrimethylammonium bromide (CTMAB) and 13.2g ( About 15ml) to analyze pure ammonia water, then add 60g ethanol, stir for 15min at a rotating speed of 300rpm, add tetraethyl orthosilicate (TEOS) according to silicon dioxide / calcium carbonate=0.2 (weight ratio), stir for 2 hours, filter, filter The cake was rinsed with an appropriate amount of ethanol, dried in an oven at a temperature of 90°C, and baked in a muffle furnace at a temperature of 550°C for 5 hours. Dissolve the sample with dilute hydrochloric acid, keep the pH below 1, and dry to obtain the product.

Embodiment 3

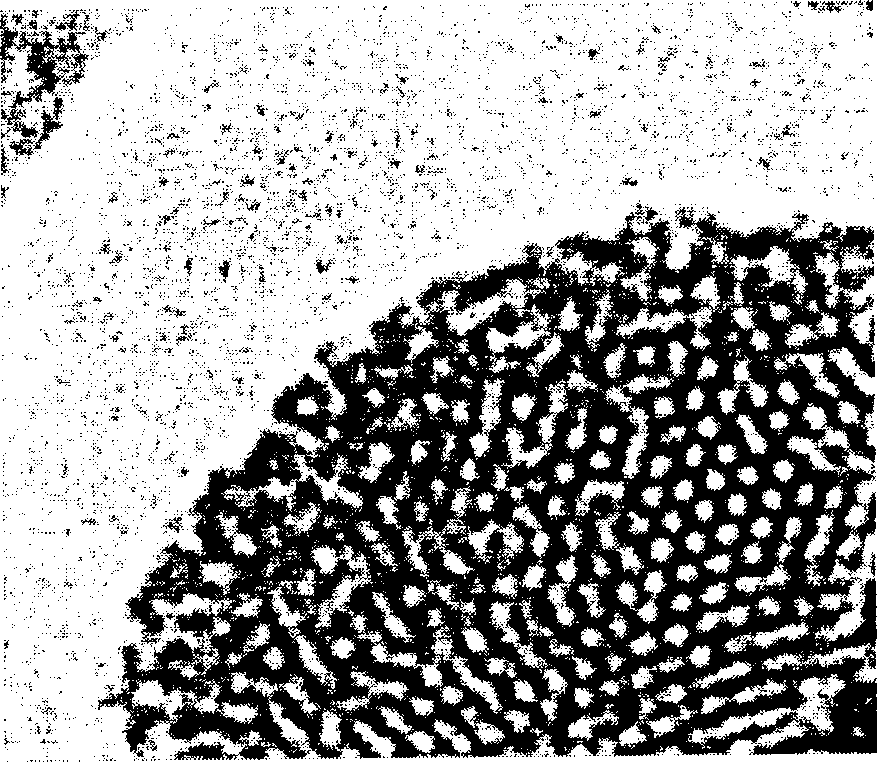

[0080] Example 3 The preparation method of thin-shell nanometer mesoporous spheres

[0081] Take by weighing barium carbonate 100nm (spherical) powder 10g, add deionized water 50g, add 3g cetyltrimethylammonium bromide (CTMAB) and 13.2g (about 15ml) analytical pure ammonia water, then add 60g ethanol, in Stir at 300rpm for 15min, add tetraethyl orthosilicate (TEOS) according to silica / barium carbonate = 0.2 (weight ratio), stir for 2 hours, filter, rinse the filter cake with an appropriate amount of ethanol, and dry in an oven at a temperature of 90 ℃, muffle furnace roasting, temperature 550 ℃, time 5h. Dissolve the sample with dilute hydrochloric acid, keep the pH below 1, and dry to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com