High-temperature resistant thermal shock resistant pipeline used in iron-making hot blast heater and preparation method of high-temperature resistant thermal shock resistant pipeline

A technology of high temperature resistance and thermal shock resistance, applied in the field of refractory materials, can solve the problems of easy damage of pipelines, achieve the effects of improving thermal shock resistance, improving high temperature mechanical properties, and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

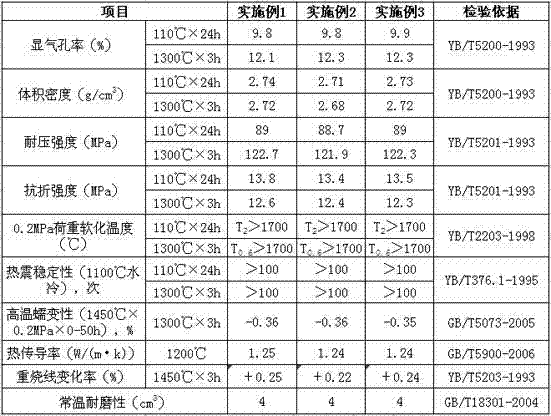

Examples

Embodiment 1

[0023] A high-temperature-resistant and thermal-shock-resistant pipe for an iron-making hot blast stove. The raw materials are composed of: 15 parts of high-alumina bauxite particle clinker with a particle size of 8-5 mm and high-alumina bauxite particles with a particle size of 5-3 mm in parts by weight. 20 parts of clinker, 15 parts of andalusite with a particle size of 3~1mm, 20 parts of andalusite with a particle size of 1~0.074mm, 7 parts of andalusite with a particle size of 200 mesh, 9 parts of brown corundum fine powder with a particle size of 300 mesh, CA-70 pure Calcium aluminate cement 4 parts, α-Al with particle size ≤ 5 microns 2 o 3 3 parts powder, ρ-Al 2 o 3 2 parts of powder, SiO with particle size ≤ 1 micron 2 5 parts of fine powder; In addition, 0.1 part of sodium tripolyphosphate and 0.05 part of sodium hexametaphosphate, 0.05 part of organic explosion-proof fiber and 1.0 part of heat-resistant stainless steel fiber were added.

[0024] A method for prep...

Embodiment 2

[0032] A high-temperature-resistant and thermal-shock-resistant pipe for an ironmaking hot blast stove, the raw materials of which are composed of: 20 parts of high-alumina bauxite particle clinker with a particle size of 8-5 mm and high-alumina bauxite particles with a particle size of 5-3 mm in parts by weight 20 parts of clinker, 15 parts of andalusite with a particle size of 3~1mm, 15 parts of andalusite with a particle size of 1~0.074mm, 5 parts of andalusite with a particle size of 200 mesh, 8 parts of brown corundum fine powder with a particle size of 300 mesh, CA-70 pure Calcium aluminate cement 3 parts, α-Al with particle size ≤ 5 microns 2 o 3 5 parts powder, ρ-Al 2 o 3 3 parts of powder, SiO with particle size ≤ 1 micron 2 6 parts of fine powder; in addition, 0.15 parts of sodium hexametaphosphate and 0.15 parts of organic explosion-proof fiber were added.

[0033] A method for preparing a high-temperature-resistant and thermal-shock-resistant pipeline for an ir...

Embodiment 3

[0035] A high-temperature-resistant and thermal-shock-resistant pipe for an iron-making hot blast stove. The raw materials are composed of: 18 parts of high-alumina bauxite particle clinker with a particle size of 8-5 mm and high-alumina bauxite particles with a particle size of 5-3 mm in parts by weight. 20 parts of clinker, 12 parts of andalusite with a particle size of 3~1mm, 18 parts of andalusite with a particle size of 1~0.074mm, 7 parts of andalusite with a particle size of 200 mesh, 9 parts of brown corundum fine powder with a particle size of 300 mesh, CA-70 pure Calcium aluminate cement 2 parts, α-Al with particle size ≤ 5 microns 2 o 3 4 parts powder, ρ-Al 2 o 3 3 parts of powder, SiO with particle size ≤ 1 micron 2 7 parts of fine powder; In addition, 0.20 parts of sodium tripolyphosphate, 0.10 parts of organic explosion-proof fiber and 1.0 part of heat-resistant stainless steel fiber were added.

[0036] A method for preparing a high-temperature-resistant and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com