Sillimanite brick for large-scale blast furnace hot blast stove and method of manufacturing the same

A production method and hot blast furnace technology, applied in the field of refractory materials, can solve the problems of poor thermal shock resistance, performance decline, poor volume stability, etc., and achieve the effect of improving and improving high temperature performance and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: Sillimanite brick for large-scale blast furnace hot blast stove and production method thereof

[0059] The raw material of sillimanite bricks is: a-Al with a particle size of 3-1 mm in weight percentage 2 o 3 40% base mullite, 45% high-purity sillimanite with particle size less than 0.5mm, 15% co-milled powder; additionally add density 1.23g / cm 3 The lignin aqueous solution is used as a binding agent, and the added amount accounts for 3% of the total weight of the above-mentioned raw materials.

[0060] The composition of the co-milled powder is: by weight percentage, corundum powder with a particle size of ≤280 mesh 25%, andalusite powder with a particle size of ≤200 mesh 25%, zirconia powder with a particle size of ≤325 mesh 10%; a-Al with a particle size of ≤625 mesh 2 o 3 20% of fine powder, 20% of combined clay with particle size ≤180 mesh.

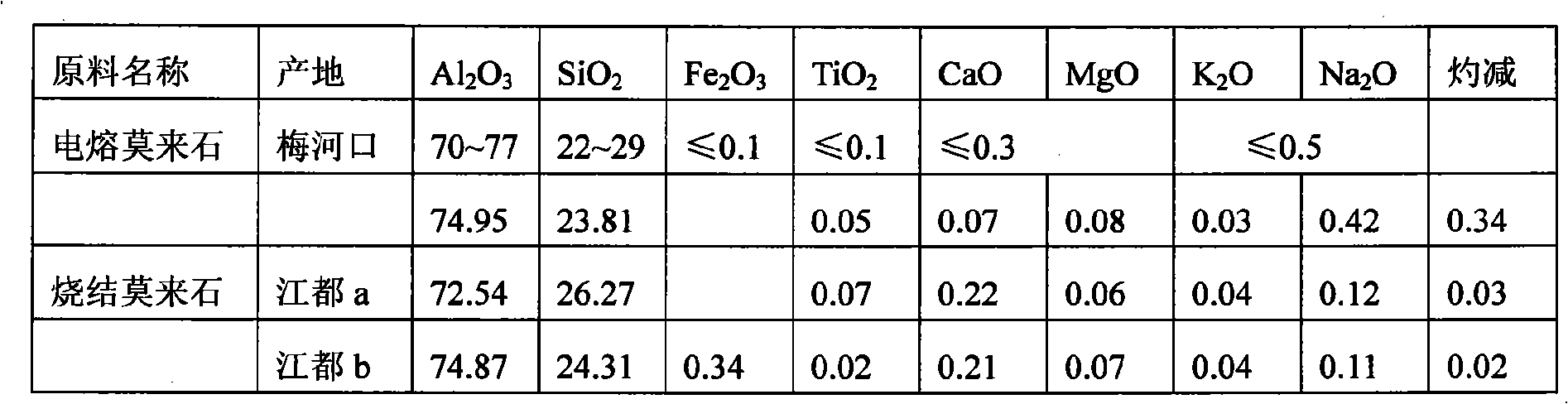

[0061] In this example a-Al 2 o 3 For base mullite, select the fused mullite from Meihekou in Table 5, s...

Embodiment 2

[0074] Embodiment 2: Sillimanite brick for large-scale blast furnace hot blast stove and production method thereof

[0075] The raw material of sillimanite bricks is: a-Al with a particle size of 3-1 mm in weight percentage 2 o 3 35% base mullite, 55% high-purity sillimanite with particle size less than 0.5mm, 10% co-milled powder; additionally add density 1.22g / cm 3 lignin aqueous solution, the addition accounts for 3% of the above-mentioned raw material gross weight.

[0076] The composition of the co-milled powder is: by weight percentage, 23% of white corundum powder with a particle size of ≤280 mesh, 22% of andalusite powder with a particle size of ≤200 mesh, 6% of zirconia with a particle size of ≤325 mesh; a-Al with a particle size of ≤625 mesh 2 o 3 29% of fine powder, 20% of combined clay with a particle size of ≤180 mesh.

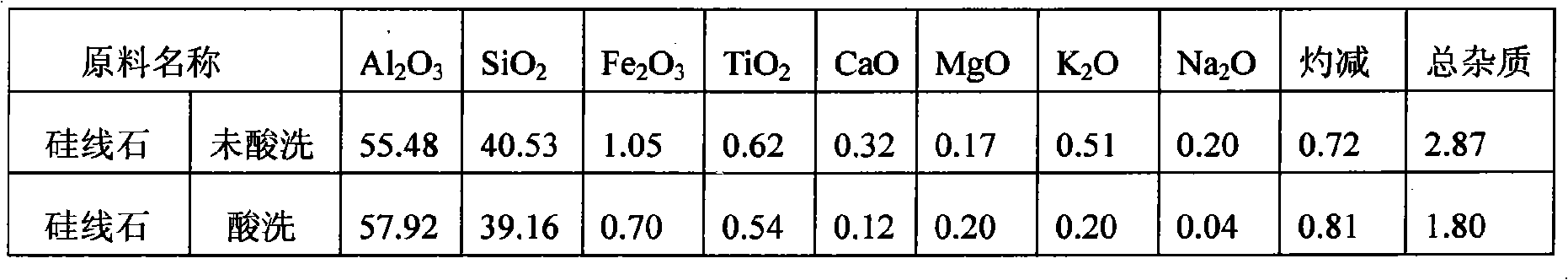

[0077] In this example a-Al 2 o 3 The base mullite is selected from the fused mullite in Meihekou in Table 5, the sillimanite is selected f...

Embodiment 3

[0080] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0081] The raw material of sillimanite brick is: a-Al 2 o 3 40% base mullite, 40% high-purity sillimanite, 20% co-grinding powder; additionally added density 1.24g / cm 3 lignin aqueous solution, the addition accounts for 5% of above-mentioned raw material gross weight.

[0082] The co-grinding powder consists of: 20% corundum powder, 25% andalusite powder, 10% zirconia; a-Al 2 o 3 Micronized powder 25%, bound clay 20%. The granularity requirements of each raw material are the same as those in Example 1, and will not be repeated.

[0083] In this example a-Al 2 o 3 The base mullite is selected from the fused mullite of Meihekou in Table 5 and the sintered mullite a produced in Jiangdu, the ratio of the two is 3:1, and the sillimanite is selected from the unacided sillimanite in Table 6, red Andalusite 2 in table 7 is selected as the pillar stone powder # .

[0084] Production method is basica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com