High temperature resistant coating for engine exhaust system

A technology for high temperature resistant coatings and exhaust systems, applied in anti-corrosion coatings, coatings, etc., can solve problems such as inability to prevent corrosive gas or liquid penetration, inability to prevent corrosion of engine exhaust systems, and easy cracking of silicone resins. Improve thermal stability and corrosion resistance, high hardness and wear resistance, good high temperature wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the above-mentioned high temperature resistant coating is introduced below.

[0037] Scheme 1: Mix and stir various raw materials of the coating of the present invention, and react at a temperature between room temperature and 150° C. to obtain the high-temperature-resistant coating of the present invention.

[0038] Scheme 2: (1) The base material and the silane coupling agent undergo a hydrolysis reaction to form a polymer network structure. The pH of the reaction system is 3-9, and the water required for the hydrolysis reaction comes from silica sol or aluminum sol, and can also be added separately. Organic solvents can be used as auxiliary agents, such as one or more of methanol, ethanol, isopropanol, butanol and propylene glycol methyl ether, to assist the hydrolysis reaction of the silane coupling agent. That is, the solvent is water or a mixture of water and an organic solvent, and the amount of the solvent is 10%-50% of the total weigh...

Embodiment

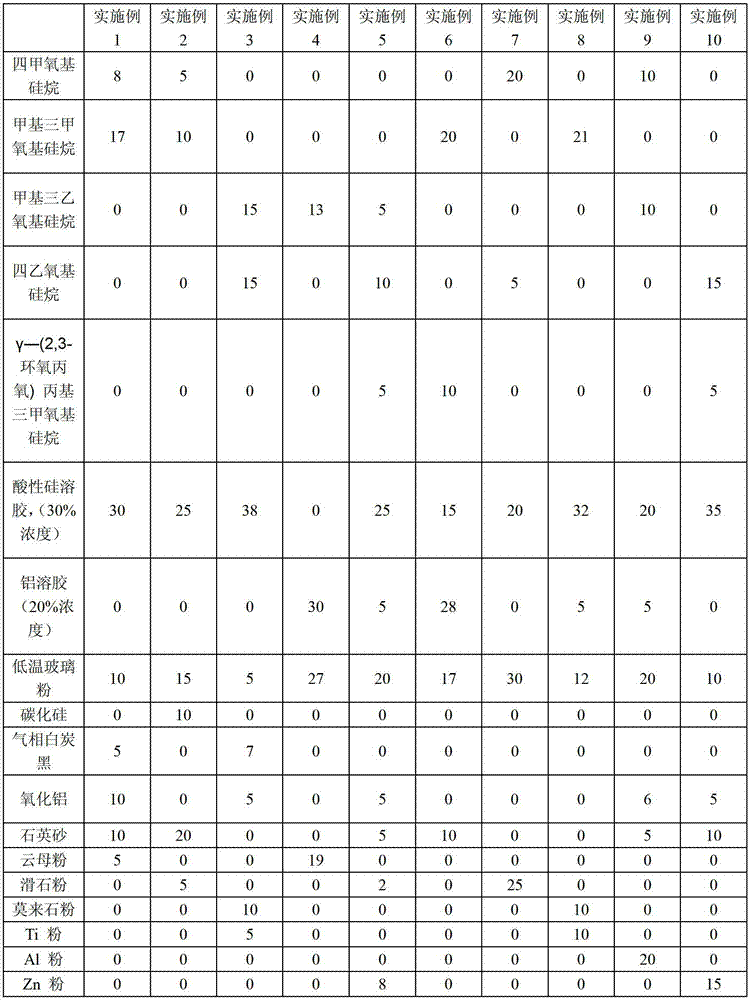

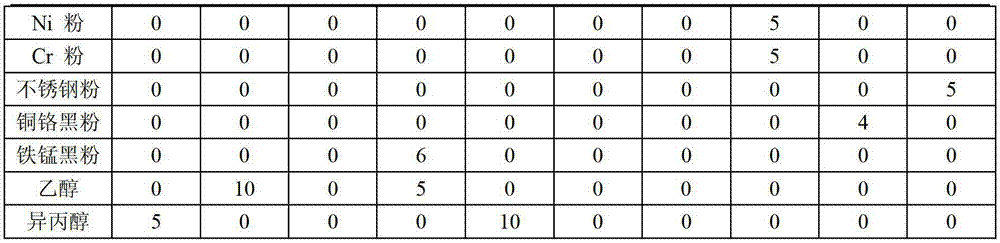

[0042] The raw material formula of each embodiment coating is as follows: (by weight ratio, unit: part)

[0043]

[0044]

[0045] The preparation method of embodiment 1-10 high temperature resistant coating of the present invention:

[0046] Use ultra-fine ball mill to pulverize the ceramic material until the particle size of the ceramic material is below 40 μm, and put it into the base material in proportion, and can mix with silane coupling agent, auxiliary agent methanol, or ethanol, or isopropanol (embodiment 1-2, 3-4) Mix in proportion, adjust the pH to 4-5 with acetic acid, then react at a temperature below 100°C, and the reaction time is 5-24h. The reaction product was cooled to room temperature, and then filtered through 200-mesh gauze to remove impurities such as oversized particles to obtain a high-temperature-resistant coating.

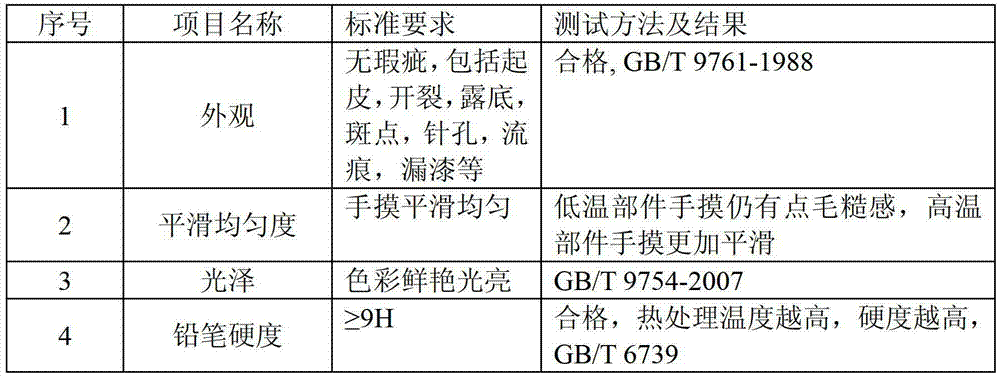

[0047] When using the high-temperature-resistant coating of the present invention, the engine parts and the exhaust manifold are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com