Boron nitride reinforced multi-element heat-resistant magnesium alloy and preparation method thereof

A technology of magnesium alloy and boron nitride, which is applied in the field of boron nitride reinforced multi-component heat-resistant magnesium alloy and its preparation, can solve the problems of difficult machining, high cost, complicated process, etc., and achieve good machining performance and manufacturing process steps Simple, promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

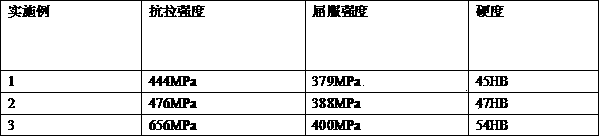

Embodiment 1

[0019] A boron nitride-reinforced multi-component heat-resistant magnesium alloy, containing: Gd: 0.55%, Al: 3.4%, Zn: 1.75%, Si: 4.2%, Ca: 0.93%, Sr: 1.02%, Nd: 0.88%, Zr: 0.17%, Sn: 1.6%, Be: 0.18%, Mn: 0.76%, Sb: 0.13%, Cu: 0.59%, boron nitride nanotube particles: 5.5%, and the balance is Mg. The size of the boron nitride nanotube particles is 90 μm.

[0020] The preparation method of the boron nitride reinforced multi-element heat-resistant magnesium alloy comprises the following steps:

[0021] (1) Raw material preparation: raw material preparation is carried out according to weight percentage content, and described raw material is pure Mg ingot, Mg-Gd master alloy, pure Al ingot, pure Zn, Al-Si master alloy, Al-Ca master alloy, Al-Sr Master alloy, Mg-Nd master alloy, Mg-Zr master alloy, pure Sn, Al-Be master alloy, Al-Mn master alloy, pure Sb, Al-Cu master alloy, boron nitride nanotube particles;

[0022] (2) Melting: The alloy is smelted in a resistance furnace with a...

Embodiment 2

[0029] A boron nitride-reinforced multi-element heat-resistant magnesium alloy contains: Gd: 0.68%, Al: 3.54%, Zn: 1.82%, Si: 4.44%, Ca: 0.96%, Sr: 1.07%, Nd: 0.98%, Zr: 0.23%, Sn: 1.7%, Be: 0.175%, Mn: 0.89%, Sb: 0.145%, Cu: 0.67%, boron nitride nanotube particles: 8%, and the balance is Mg. The size of the boron nitride nanotube particles is 50 μm.

[0030] A boron nitride reinforced multi-component heat-resistant magnesium alloy, comprising the following steps:

[0031] (1) Raw material preparation: raw material preparation is carried out according to weight percentage content, and described raw material is pure Mg ingot, Mg-Gd master alloy, pure Al ingot, pure Zn, Al-Si master alloy, Al-Ca master alloy, Al-Sr Master alloy, Mg-Nd master alloy, Mg-Zr master alloy, pure Sn, Al-Be master alloy, Al-Mn master alloy, pure Sb, Al-Cu master alloy, boron nitride nanotube particles;

[0032] (2) Melting: The alloy is smelted in a resistance furnace with a protective gas atmosphere....

Embodiment 3

[0039] A boron nitride reinforced multi-component heat-resistant magnesium alloy, containing Gd: 0.65%, Al: 3.55%, Zn: 1.85%, Si: 4.25%, Ca: 0.96%, Sr: 1.05%, Nd: 0.9% by weight %, Zr: 0.24%, Sn: 1.6%, Be: 0.18%, Mn: 0.85%, Sb: 0.13%, Cu: 0.75%, boron nitride nanotube particles: 12%, the balance is Mg, the nitrogen The size of boron oxide nanotube particles is 10 μm.

[0040] The preparation method of the boron nitride reinforced multi-element heat-resistant magnesium alloy comprises the following steps:

[0041] (1) Raw material preparation: raw material preparation is carried out according to weight percentage content, and described raw material is pure Mg ingot, Mg-Gd master alloy, pure Al ingot, pure Zn, Al-Si master alloy, Al-Ca master alloy, Al-Sr Master alloy, Mg-Nd master alloy, Mg-Zr master alloy, pure Sn, Al-Be master alloy, Al-Mn master alloy, pure Sb, Al-Cu master alloy, boron nitride nanotube particles;

[0042] (2) Melting: The alloy is smelted in a resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com