Preparation method of titanium and titanium alloy surface black protective film for surgical implantation

A surgical implant, titanium alloy technology, applied in the surface reaction electrolytic coating, medical science, electrolytic coating, etc., can solve the problem that the bonding force of the anodized film cannot fully meet the requirements of use, and the white and black oxide film cannot be obtained. Film color change and other problems, to achieve the effect of novel design, consistent thickness and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

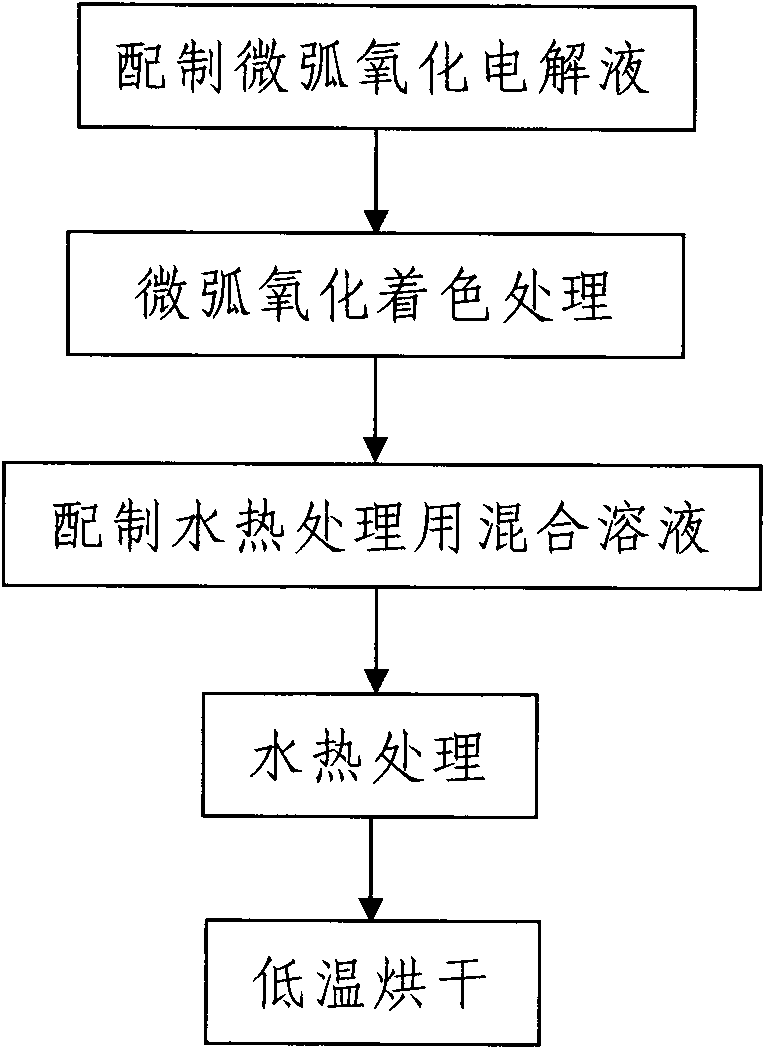

[0028] like figure 1 As shown, the preparation method of titanium and titanium alloy surface black protective film for surgical implant of the present invention may further comprise the steps:

[0029] Step 1. Perform micro-arc oxidation coloring treatment on the surface of the titanium or titanium alloy sample to be treated. The process is as follows:

[0030] 101. Preparation of micro-arc oxidation electrolyte: the electrolyte is made of (NaPO 3 ) 6 , NH 4 VO 3 、Na 2 SiO 3 It is uniformly mixed with NaOH solution and its pH value is 9-11; in each L of electrolyte (NaPO 3 ) 6 The content is 5~20g, NH 4 VO 3 The content is 3~25g, Na 2 SiO 3 The content is 3 ~ 10g.

[0031] 102. Micro-arc oxidation coloring treatment: completely immerse the titanium or titanium alloy sample in a container containing the electrolyte, and use micro-arc oxidation equipment to perform micro-arc oxidation coloring treatment on the surface of the titanium or titanium alloy sample until A...

Embodiment 1

[0037] In this embodiment, the processed titanium or titanium alloy sample is a pure titanium sample. First, the micro-arc oxidation electrolyte is prepared, and the prepared micro-arc oxidation electrolyte is made of (NaPO 3 ) 6 , NH 4 VO 3 、Na 2 SiO 3 It is uniformly mixed with NaOH solution and its pH value is 10; and in each L of electrolyte (NaPO 3 ) 6 The content is 10g, NH 4 VO 3 The content is 20g, Na 2 SiO 3 The content is 8g. During the preparation process, the pH value of the electrolyte solution is adjusted by adjusting the amount of NaOH solution added. After preparing the micro-arc oxidation electrolyte, completely immerse the pure titanium sample to be processed into the prepared electrolyte, and perform micro-arc oxidation coloring treatment: during the micro-arc oxidation coloring process, the work of the micro-arc oxidation power supply The frequency is 600Hz and its duty cycle is 16%; when the micro-arc oxidation coloring treatment starts, the op...

Embodiment 2

[0040] In this example, the difference from Example 1 is: the pH value of the prepared micro-arc oxidation electrolyte is 9; and in every L of electrolyte (NaPO 3 ) 6 The content is 5g, NH 4 VO 3 The content is 3g, Na 2 SiO 3 The content is 3g. When performing micro-arc oxidation coloring treatment, the operating frequency of the micro-arc oxidation power supply is 500Hz and its duty cycle is 14%. When the micro-arc oxidation coloring treatment starts, the operating voltage of the micro-arc oxidation power supply is 300V, and then Carrying out the micro-arc oxidation coloring treatment and raising the working voltage of the micro-arc oxidation power supply to 450V after arcing on the surface of the pure titanium sample, the boosting time used for raising the working voltage of the micro-arc oxidation power supply to 450V The treatment time for micro-arc oxidation coloring treatment is 20 minutes. Na in each L of mixed solution prepared 3 PO 4 12H 2 The content of O wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com