Metallic fiber gradient hole sound absorbing material and method for preparing same

A technology of metal fiber and sound-absorbing materials, which is applied in the direction of sound-emitting devices and instruments, can solve problems such as no binding force, no sound-absorbing effect, sound leakage, etc., and achieve a stable increase in sound absorption coefficient, strong operability, The effect of simple preparation process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The metal fiber gradient hole sound-absorbing material prepared in this example is composed of two layers of metal fiber porous material layers stacked together and with different structures. Material. The two metal fiber porous material layers are FeCrAl fiber material, and they are metal fiber porous material layer 1 with a pore diameter of 168 μm and metal fiber porous material layer 2 with a pore diameter of 79 μm. The metal fiber porous material layer 1 and the metal fiber porous material layer 2 are both circular in shape and have an outer diameter of Φ29mm. The metal fiber porous material layer 1 is stacked on the metal fiber porous material layer 2 and the two Sintered into one and form a monolithic sound-absorbing material.

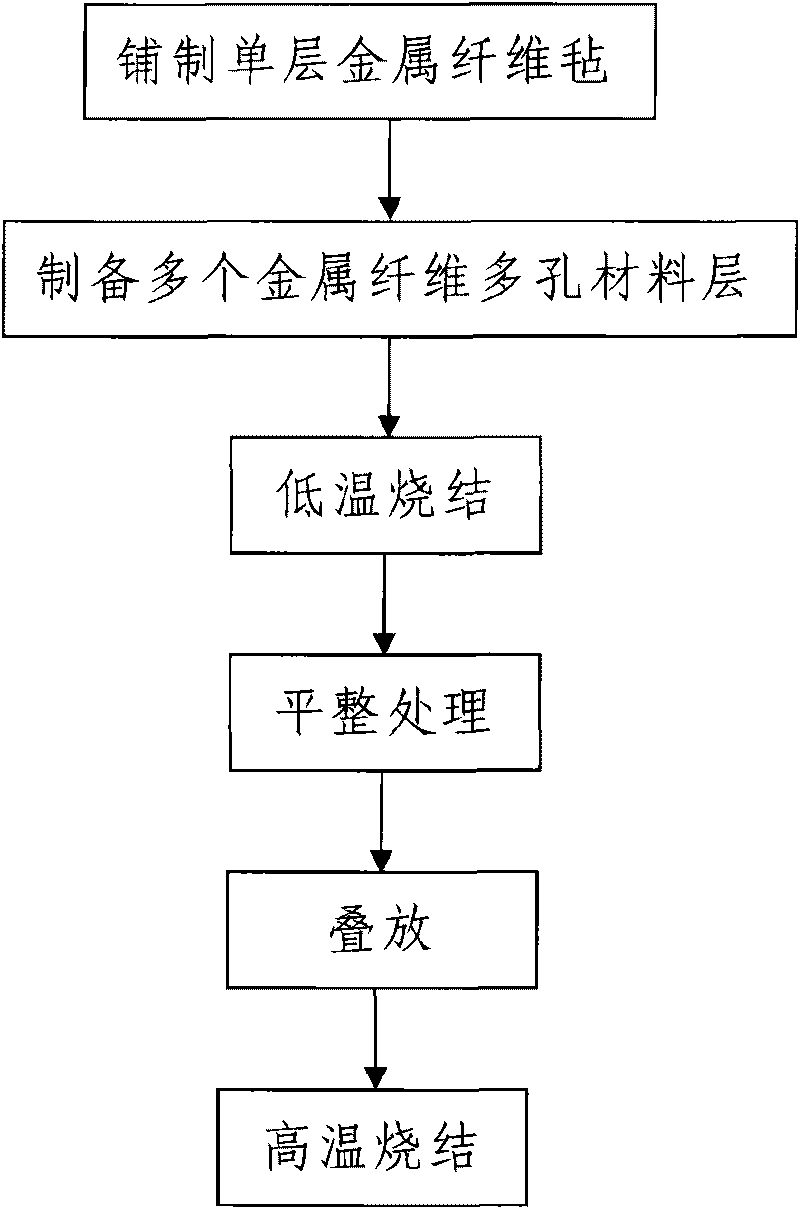

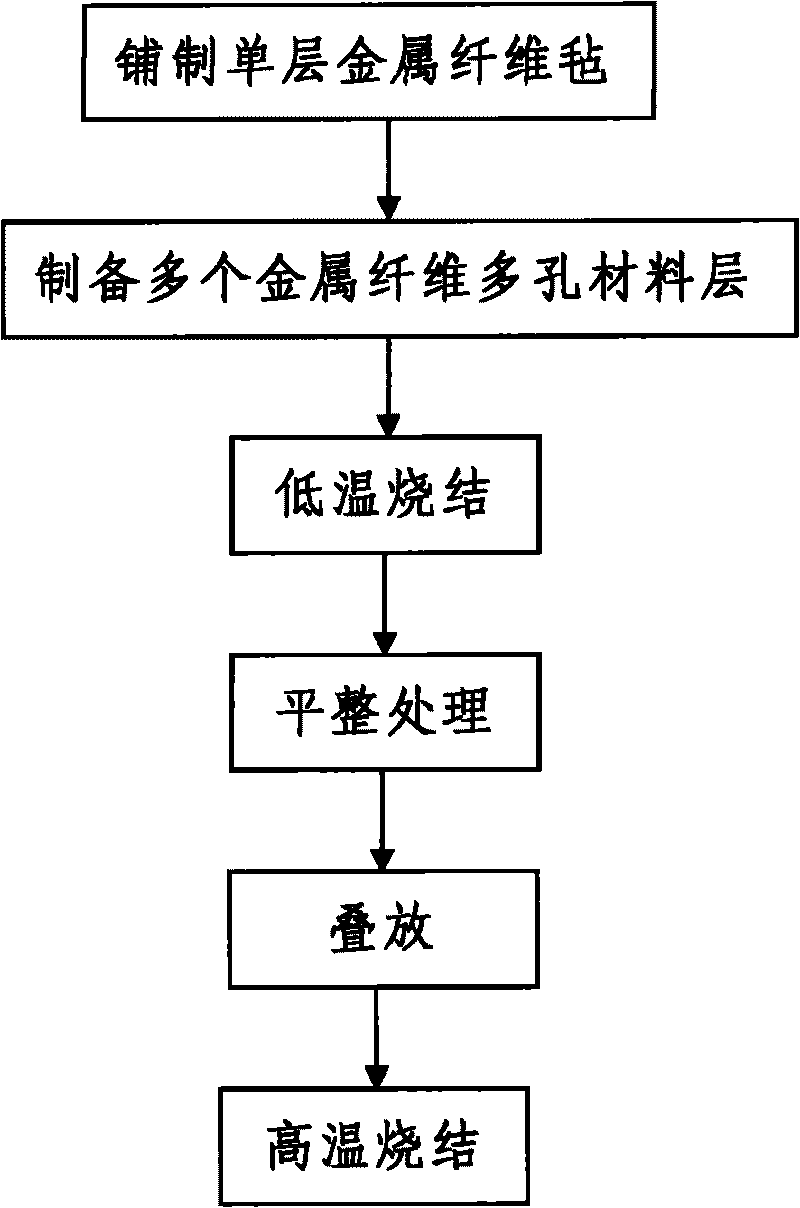

[0040] In this example, when preparing the metal fiber gradient hole sound-absorbing material, the following steps are included:

[0041] Step 1. Lay a single-layer metal fiber felt: select Fe-Cr-Al fibers with a fiber diameter of 20 μm,...

Embodiment 2

[0049] In this example, the difference from Example 1 is that the metal fiber gradient hole sound-absorbing material prepared in this example is composed of three layers of metal fiber porous material layers stacked together with different structures. The metal fiber porous material layer is sintered to form a whole sound-absorbing material. The three metal fiber porous material layers are all stainless steel fiber materials, and they are the metal fiber porous material layer 1 with a porosity of 97%, the metal fiber porous material layer 2 with a porosity of 94%, and the metal fiber porous material layer 2 with a porosity of 91%. Metal fiber porous material layer three. The metal fiber porous material layer 1, the metal fiber porous material layer 2 and the metal fiber porous material layer 3 are all square in shape and have a size of 100mm×100mm, and the metal fiber porous material layer 2 is stacked on the metal fiber porous material On the third layer, the metal fiber por...

Embodiment 3

[0059] In this example, the difference from Example 1 is that the metal fiber gradient hole sound-absorbing material prepared in this example is composed of four layers of metal fiber porous material layers stacked together with different structures. The layers of the fibrous porous material are sintered to form a monolithic sound-absorbing material. The four metal fiber porous material layers are all stainless steel fiber materials and their pore diameters are metal fiber porous material layer 1 of 200 μm, metal fiber porous material layer 2 of 150 μm, metal fiber porous material layer 3 of 100 μm and metal fiber of 50 μm Porous material layer four. The metal fiber porous material layer 1, the metal fiber porous material layer 2, the metal fiber porous material layer 3 and the metal fiber porous material layer 4 are all square in shape and have a size of 170mm×170mm, and the metal fiber porous material layer 3 Then stacked successively on the metal fiber porous material laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com