Semi-rigid concrete and preparation process thereof

A concrete and semi-rigid technology, applied in the field of semi-rigid concrete and its preparation, can solve the problems of concrete cracks or fractures, large elastic modulus of concrete, high rigidity, etc., and achieve the effects of reuse, easy storage, and easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the prepared semi-rigid concrete is the concrete mixed by replacing part of the fine aggregate of ordinary concrete with a flexible material, and the quality of the replaced fine aggregate is the same as that of the flexible material used for replacement. The prepared semi-rigid concrete is concrete with elastic modulus ε1, where ε0 is the modulus of elasticity of the ordinary concrete.

[0037] In this example, the mass of the replaced fine aggregate is 15% of the total mass of the fine aggregate.

[0038] During actual preparation, the percentage of the mass of the replaced fine aggregate to the total mass of the fine aggregate can be adjusted according to specific needs, and the mass of the replaced fine aggregate is not greater than 60% of the total mass of the fine aggregate.

[0039] In this embodiment, the composition of the flexible material is by mass: 35% rubber powder, 35% rubber particles, 1% polypropylene fiber, 5% fly ash, and 24% m...

Embodiment 2

[0077] In this example, the difference between the prepared semi-rigid concrete and Example 1 is that the quality of the replaced fine aggregate is 30% of the total mass of the fine aggregate.

[0078] In this embodiment, the remaining components and proportions of the prepared semi-rigid concrete are the same as those in Embodiment 1.

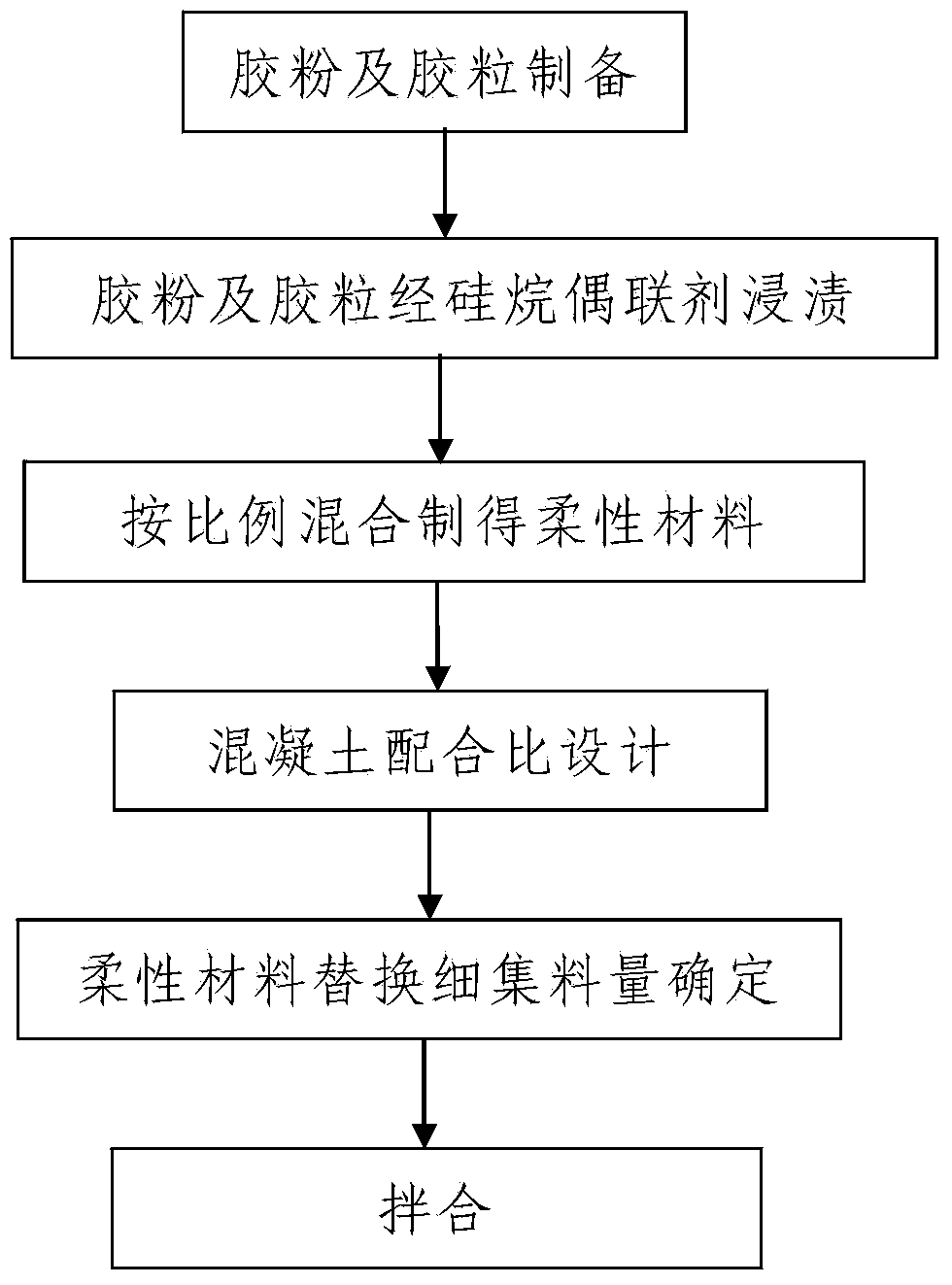

[0079] In this example, using figure 1 The preparation process shown is for the preparation of semi-rigid concrete, and the preparation process steps and process parameters adopted are the same as those in Example 1.

[0080] In the present embodiment, after the preparation of the semi-rigid concrete is completed, the slump and bulk density of the prepared concrete and the compressive strength of the constructed concrete structure are tested. The test results are as follows: the slump is 120mm, and the bulk density is 2270Kg / m 3 , the 7-day compressive strength of the formed concrete structure constructed by the semi-rigid concrete is 13.2MP...

Embodiment 3

[0082] In this example, the difference between the prepared semi-rigid concrete and Example 1 is that the quality of the replaced fine aggregate is 45% of the total mass of the fine aggregate.

[0083] In this embodiment, the remaining components and proportions of the prepared semi-rigid concrete are the same as those in Embodiment 1.

[0084] In this example, using figure 1 The preparation process shown is for the preparation of semi-rigid concrete, and the preparation process steps and process parameters adopted are the same as those in Example 1.

[0085] In the present embodiment, after the preparation of the semi-rigid concrete is completed, the slump and bulk density of the prepared concrete and the compressive strength of the constructed concrete structure are tested. The test results are as follows: the slump is 130mm, and the bulk density is 2100Kg / m 3 , the 7-day compressive strength of the formed concrete structure constructed by the semi-rigid concrete is 9.0MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com