Sulfoaluminate cement-based self-leveling mortar and preparation method thereof

A technology of sulphoaluminate cement and self-leveling mortar, which is applied in the field of building materials, can solve the problems of low early strength of compatibility, large negative impact on the mechanical strength of mortar, and large amount of cementitious materials, so as to improve segregation and secretion. Water phenomenon, mortar workability and mechanical properties have little negative impact, and the effect of small proportion of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A sulphoaluminate cement-based self-leveling mortar, the raw materials for preparing the mortar include the following materials by weight in addition to water: 11 parts of ordinary Portland cement, 23 parts of sulphoaluminate cement, 6 parts of natural gypsum, 48 parts of natural river sand for fine aggregate, 12 parts of heavy calcium powder for filler, 0.24 part of water reducer, 0.12 part of retarder, 0.12 part of early strength agent, 0.40 part of latex powder, and 0.032 part of thickener.

[0027] The specific preparation method of the above-mentioned sulfoaluminate cement-based self-leveling mortar is as follows:

[0028] Weigh the above-mentioned raw materials according to the ratio, and dry-mix fully; weigh the water according to the set water-cement ratio, and then pour the dry-mixed materials into the mixing container. The mixing procedure is: at low speed (100-150r / min) After stirring slowly for 50-70s, scrape the powder adhered to the wall into the slurry, a...

Embodiment 2

[0032] A sulphoaluminate cement-based self-leveling mortar, the raw material for preparing the mortar includes the following materials by weight in addition to water: 17 parts of ordinary Portland cement, 17 parts of sulphoaluminate cement, and 6 parts of natural gypsum , 48 parts of fine aggregate natural river sand, 12 parts of heavy calcium powder for filler, 0.24 part of water reducer, 0.16 part of retarder, 0.12 part of early strength agent, 0.40 part of latex powder, and 0.024 part of thickener.

[0033] The self-leveling mortar was prepared by the same method and water-cement ratio as in Example 1, and the performance parameters of the mortar were tested by the same test method as in Example 1. For specific results, see Sample 2 in Attached Table 1.

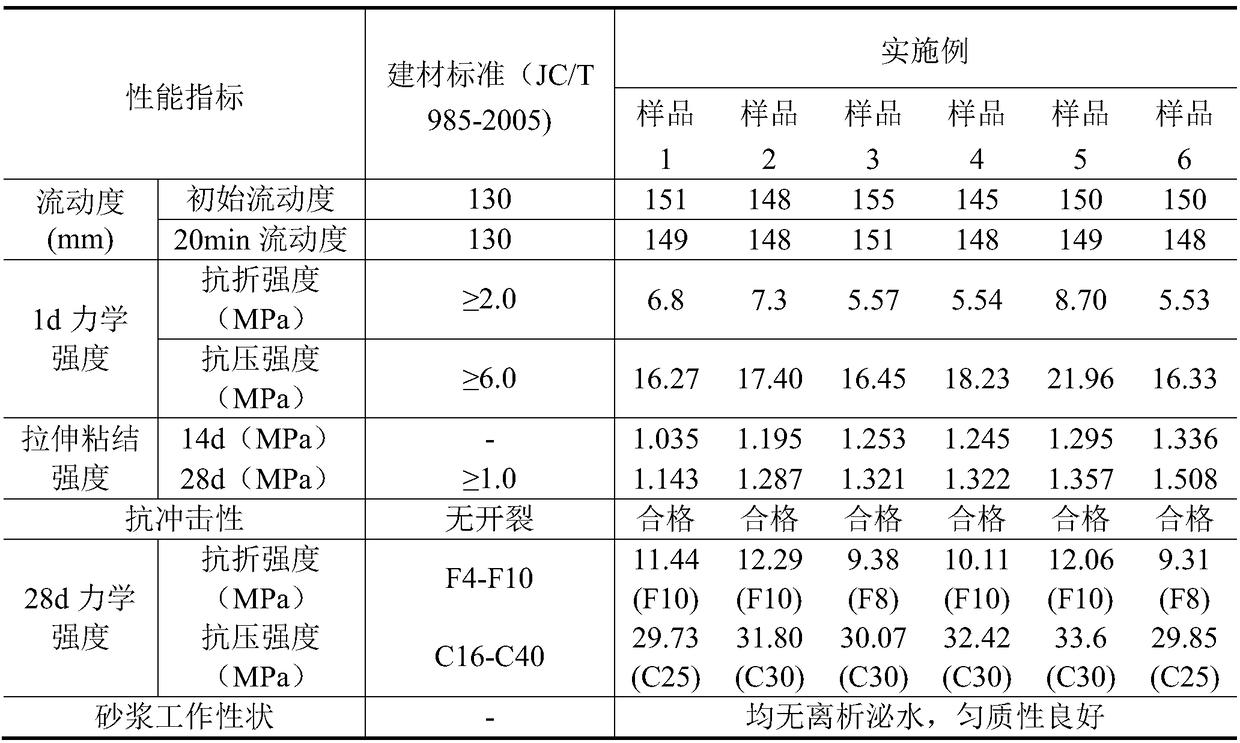

[0034] It can be seen from Table 1 that the obtained sulphoaluminate cement-based self-leveling mortar has good homogeneity and no segregation and bleeding phenomenon, and compared with the building material standard JC / T 9...

Embodiment 3

[0036]A sulphoaluminate cement-based self-leveling mortar, the raw material for preparing the mortar includes the following materials by weight in addition to water: 17 parts of ordinary Portland cement, 17 parts of sulphoaluminate cement, and 6 parts of natural gypsum , 36 parts of fine aggregate natural river sand, 24 parts of heavy calcium powder for filler, 0.24 part of water reducer, 0.16 part of retarder, 0.12 part of early strength agent, 0.40 part of latex powder, and 0.012 part of thickener.

[0037] The self-leveling mortar was prepared by the same method and water-cement ratio as in Example 1, and the performance parameters of the mortar were tested by the same test method as in Example 1. See sample 3 in Attached Table 1 for specific results.

[0038] It can be seen from Table 1 that the obtained sulphoaluminate cement-based self-leveling mortar has good homogeneity and no segregation bleeding phenomenon, and compared with the building material standard JC / T 985-200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com