Active packaging film based on essential oil/beta-cyclodextrin inclusion compound and preparation method for active packaging film

A technology of cyclodextrin inclusion compound and packaging film, which is applied in the field of packaging materials to achieve high-efficiency bacteriostatic activity, inhibited growth, and good transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 40g of polyvinyl alcohol, 1g of sodium lauryl sulfate and 8ml of ethylene glycol in a 500ml beaker, and add 250ml of water. The beaker was placed in a constant temperature water bath and heated to 60°C under low-speed stirring to obtain dispersion A. Weigh 5g of essential oil / β-cyclodextrin inclusion compound into a 250ml beaker, add 50ml of water, place the beaker in an ultrasonic oscillator for 15min until the essential oil / β-cyclodextrin inclusion compound is more evenly dispersed in water, Dispersion B was obtained. Slowly add dispersion B to dispersion A to obtain dispersion C. Continue heating the dispersion C to 95°C-100°C under low-speed stirring until the polyvinyl alcohol is completely melted. Take it out and cool it to about 60°C, then defoam in vacuum to obtain the film-forming liquid. The film-forming solution was placed in a 50°C water bath to keep warm for later use. Pour the film-forming liquid into the hopper of the casting film-forming machine...

Embodiment 2

[0030] Take 40g of polyvinyl alcohol, 1g of sodium lauryl sulfate and 5ml of ethylene glycol in a 500ml beaker, and add 250ml of water. Place the beaker in a constant temperature water bath and heat to 60°C under low-speed stirring to obtain dispersion D. Weigh 8g of essential oil / β-cyclodextrin inclusion compound into a 250ml beaker, add 50ml of water, and place the beaker in an ultrasonic oscillator for 15 minutes until the essential oil / β-cyclodextrin inclusion compound is more evenly dispersed in water, Dispersion E was obtained. Slowly add dispersion E to dispersion D to obtain dispersion F. Continue heating the dispersion F to 95°C-100°C under low-speed stirring until the polyvinyl alcohol is completely melted. Take it out and cool it to about 60°C, then defoam in vacuum to obtain the film-forming liquid. The film-forming solution was placed in a 50°C water bath to keep warm for later use. Pour the film-forming liquid into the hopper of the casting film-forming machi...

Embodiment 3

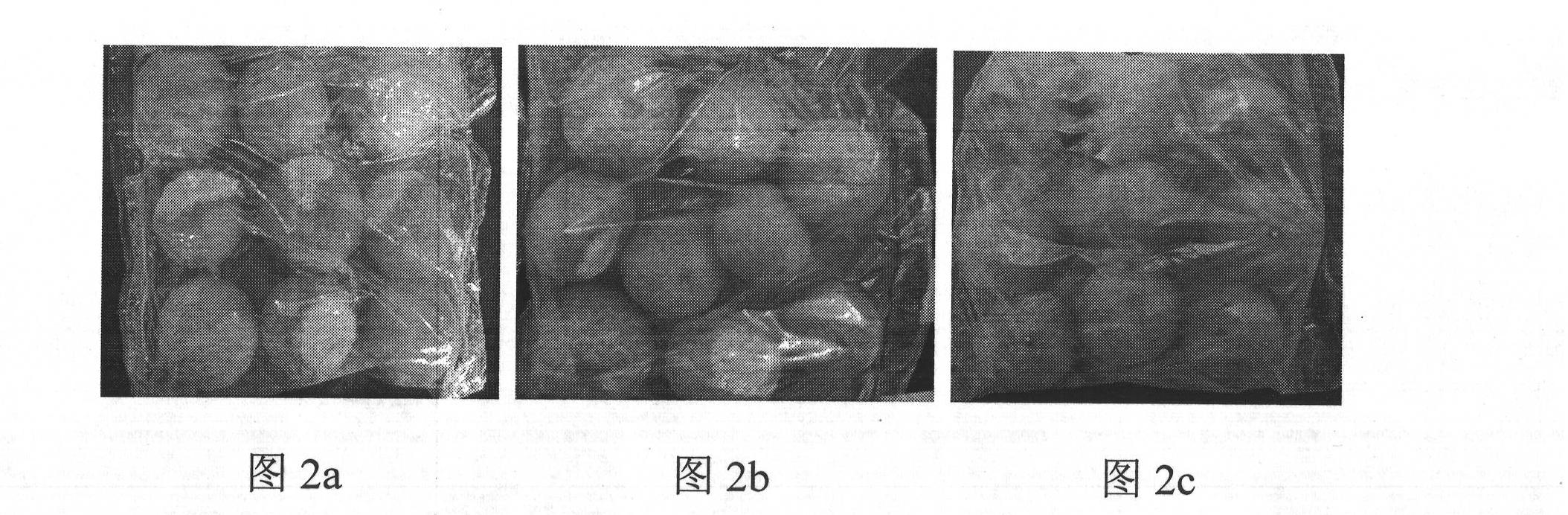

[0032] Experimental results of active packaging films used for the preservation of tangerines.

[0033]In this example, Tangerine is used as a perishable food. Buy seasonal tangerines from the supermarket, and select the same size, no damage, no disease, ripe and fresh tangerines. Wash the tangerines with clean water first, then with sterile water, and drain. Cut the films prepared in Examples 1 and 2 into 15×15 cm squares, and heat seal them into bags with a heat sealer. The fruits were randomly divided into multiple groups, and each group of 9 fruits was put into a film bag, and each treatment was repeated 3 times. And the non-antibacterial PVA packaging film was used as a control to observe the effect of active packaging film on the preservation effect of Shatangju. After 30 days from the beginning of the experiment, it was observed that the shatangju in the packaging film prepared by the scheme of Example 2 did not rot after 30 days of storage, and the sensory sensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com