Angle adjustable corner section bar system for curtain wall

An angle-adjusting and cornering technology, applied in the field of a curtain wall corner system, can solve the problems of limiting the application range of glass curtain walls, numerous corner profile molds, difficult construction, installation and positioning, etc., and achieves low production cost, short processing and production cycle, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

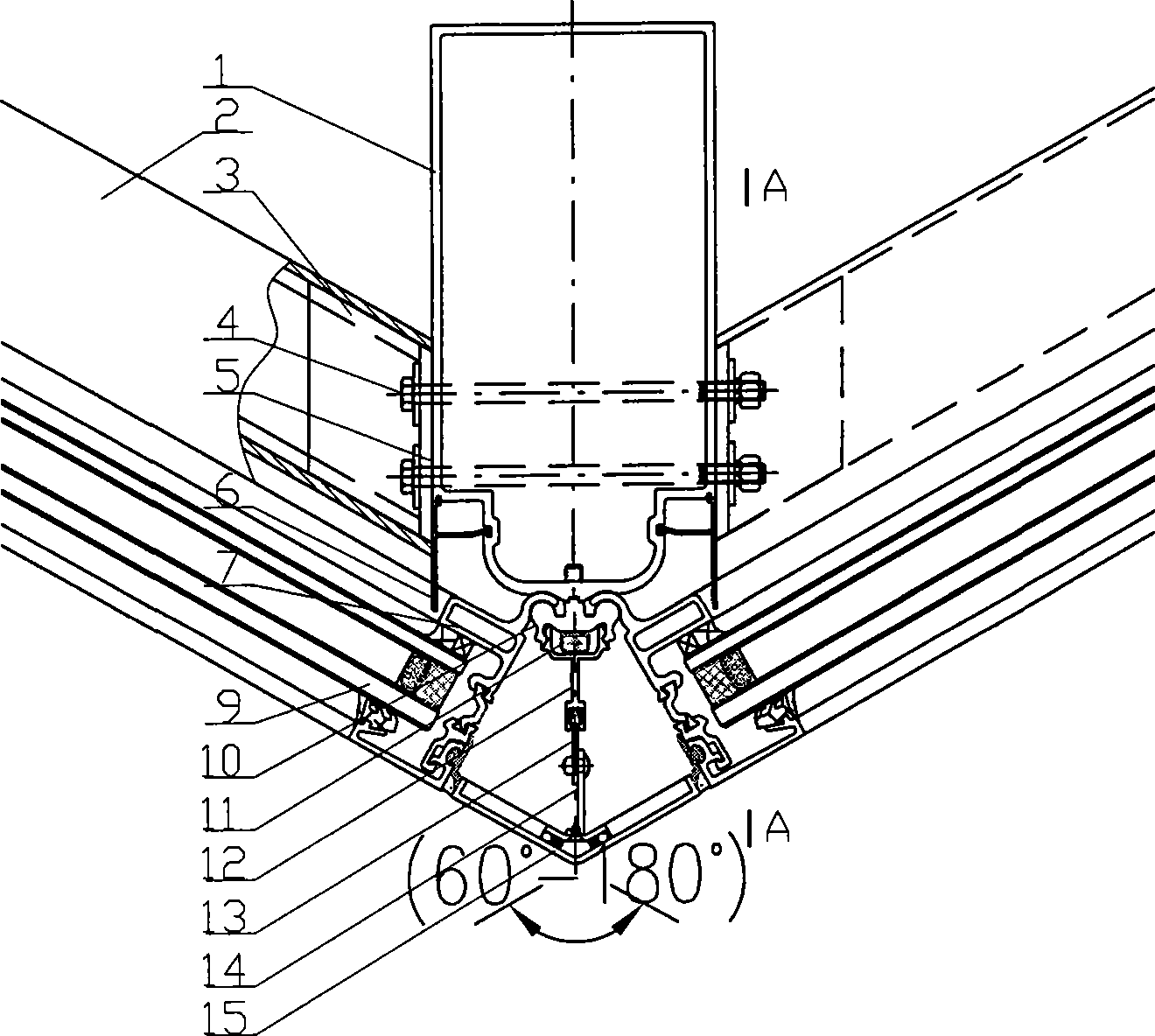

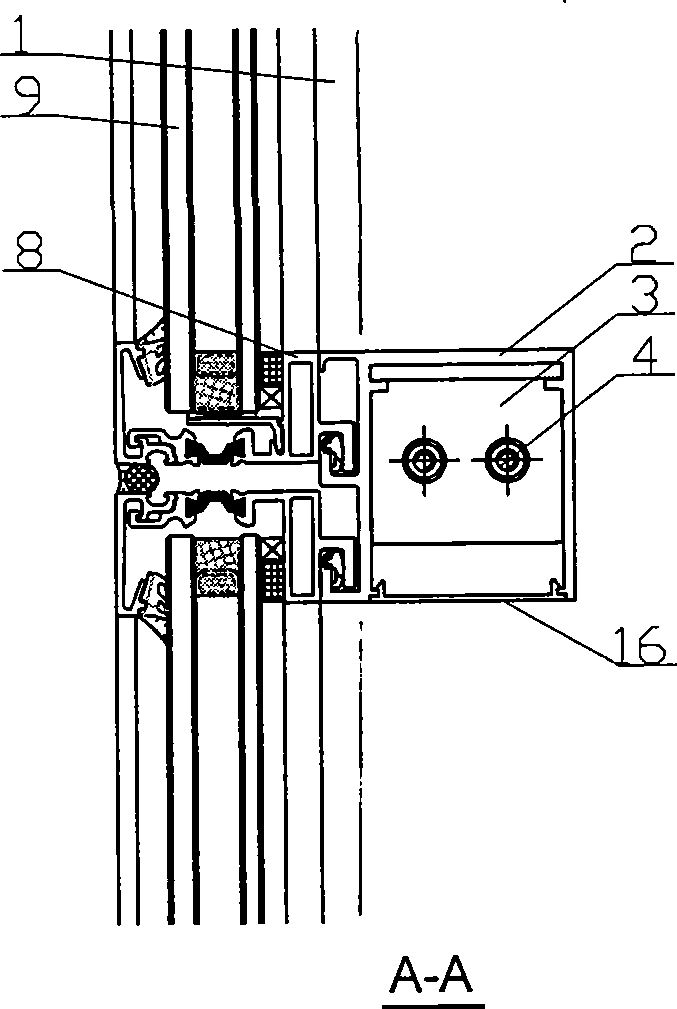

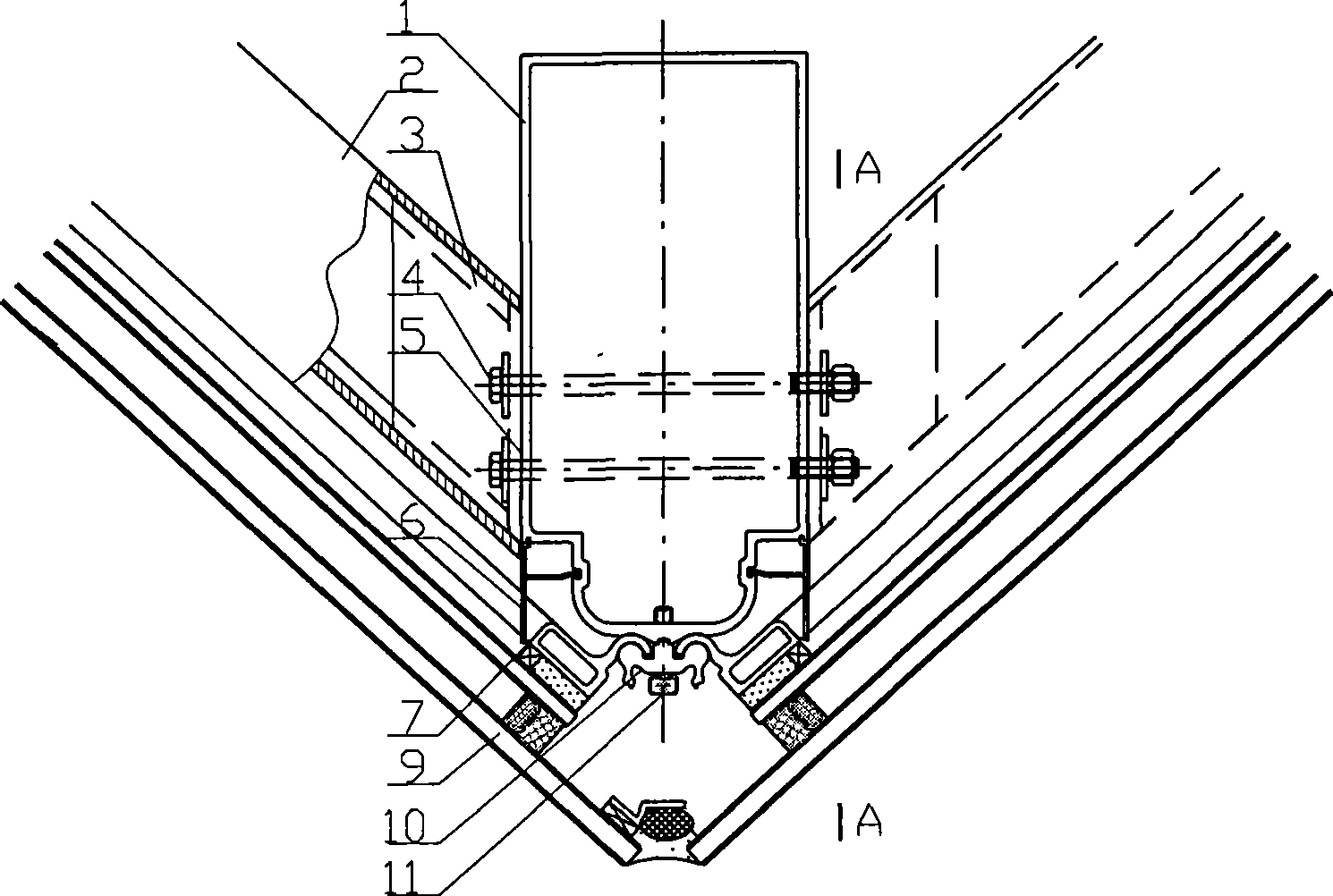

[0018] Refer to attached Figure 1-10 , The angle-adjustable corner profile system for curtain wall includes corner column 1, corner beam 2, connecting corner code 3, insulating gasket 5, beam cover plate 16, corner sub-frame 7, common sub-frame 8, curtain wall panel 9, corner press block 10 and side sealing gland 6.

[0019] Install the corner column 1 of the curtain wall according to the design requirements, then install the connecting corner code 3 into the end of the corner beam 2, and then install the insulating gasket 5 together with the corner beam 2 and the connecting corner code 3 on the corner column 1 through the connecting bolt 4 , install crossbeam cover plate 16 after adjusting. The corner sub-frame 7 and ordinary sub-frame 8 are bonded to the processed curtain wall panel 9 with silicone structural adhesive, placed in a qualified workshop for maintenance, and transported to the construction site after the silicone structural adhesive is cured. Hook the ordinary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com