Technology of making automobile engine cover with carbon fiber reinforcement resin-based composite material

A technology for reinforcing resin base and automobile engine, which is applied in the technical field of carbon fiber reinforced resin matrix composite material for making automobile engine cover, can solve the problems of unstable product quality, low mechanical properties, slow processing speed, etc., and is conducive to environmental protection and The effect of human health, low labor cost requirements, and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

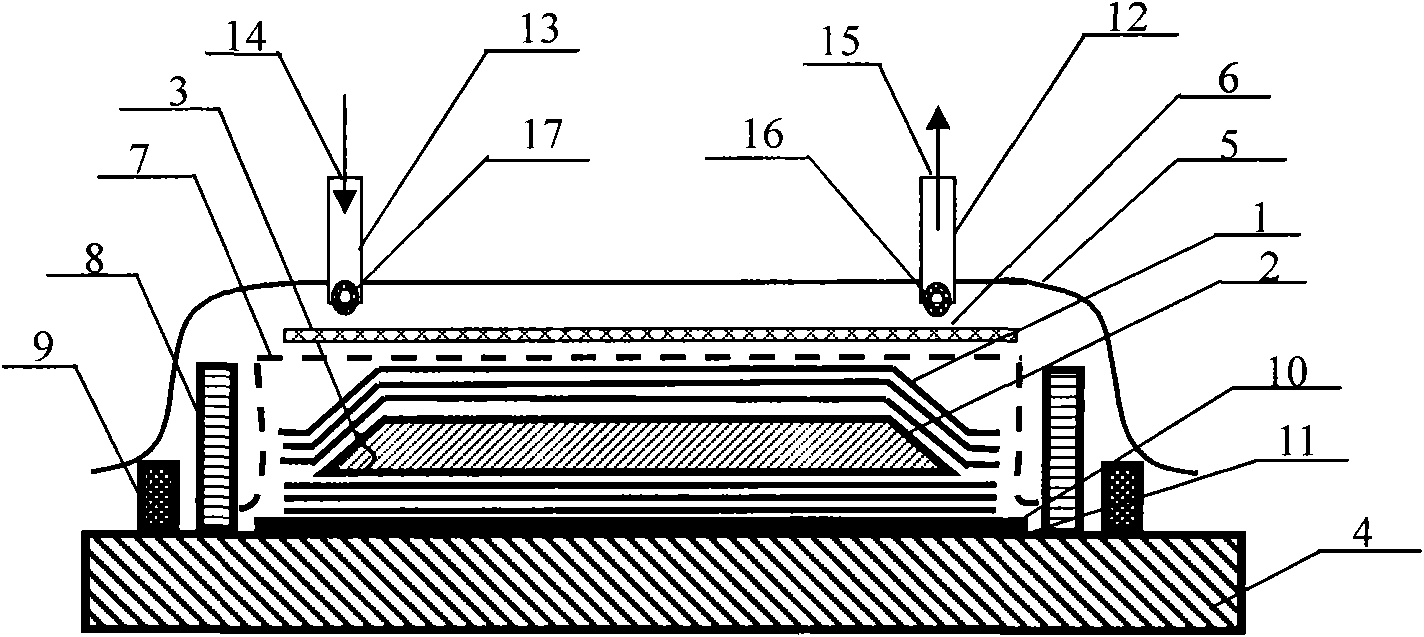

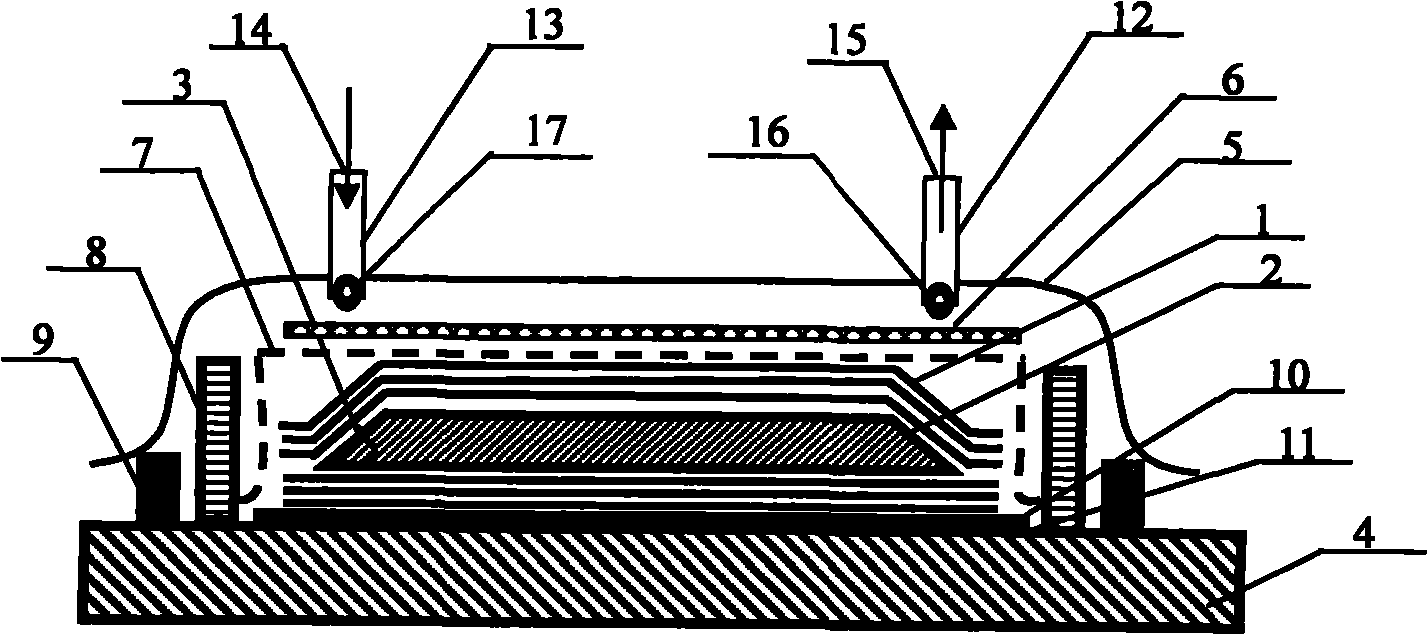

[0030] In this embodiment, a process for making an automobile engine cover from a carbon fiber-reinforced resin-based composite material comprises the following steps, and its process structure is as follows: figure 1 Shown:

[0031] 1. Mold cleaning and preparation: the surface size of the mold 4 is 160×110 square centimeters, the surface of the mold 4 is polished smooth with 1000 mesh sandpaper, and then the surface of the mold 4 is wiped clean with alcohol;

[0032] 2. Apply the sealing agent: After the alcohol on the surface of the mold 4 is completely volatilized, apply the sealing agent 11 evenly on the surface of the mold 4, then let it stand for 30 minutes, and repeat this operation once;

[0033] 3. Paste the sealing tape: paste the sealing tape 9 around the surface of the mold 4 and 15 cm away from the edge of the workpiece;

[0034] 4. Apply release agent: evenly apply release agent 10 on the surface of the mold 4 and inside the sealing tape 9, then let it stand fo...

Embodiment 2

[0042] In this embodiment, a process for making an automobile engine cover from a carbon fiber-reinforced resin-based composite material comprises the following steps, and its process structure is as follows: figure 1 Shown:

[0043] Steps 1, 2, 3, and 4 are identical to steps 1, 2, 3, and 4 in Example 1;

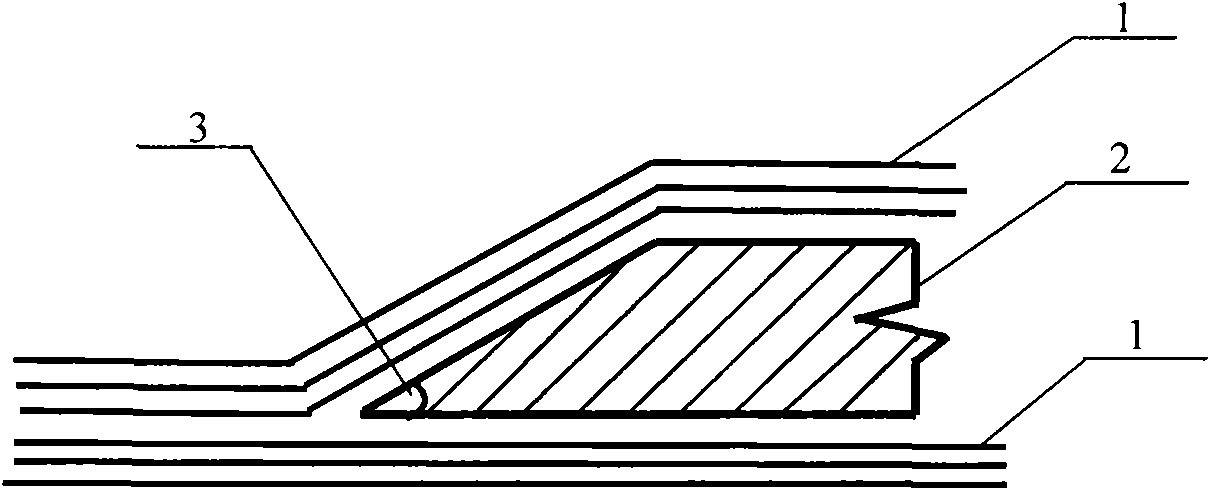

[0044] 5. Cutting reinforcing material: Cut Toray T700-12K carbon fiber fabric 1 according to the size of mold 4. The carbon fiber fabric 1 is carbon fiber twill fabric and four-axis warp knitted fabric with a size of 150×100 square centimeters. Cut 2 pieces each. The cut carbon fiber twill fabric 1 is dried in an oven at 100°C for 30 minutes; a foam core material 2 similar in shape to the mold 4 is cut out, the foam core material 2 is PVC foam, and the surface size is 140 × 90 square centimeters. The edge of the foam core material 2 is cut into a tapered shape, and the tapered angle is 45°;

[0045] 6. Lay reinforcement material: pave reinforcement material on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com