Individualized reversal design and manufacturing method for full knee joint replacing prosthesis

A technology of total knee replacement and reverse design, applied in the direction of knee joints, prostheses, elbow joints, etc., can solve the problems of inability to realize individualized design and customized manufacturing of knee joint prostheses, and achieve a high degree of individual fit , short processing cycle and optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

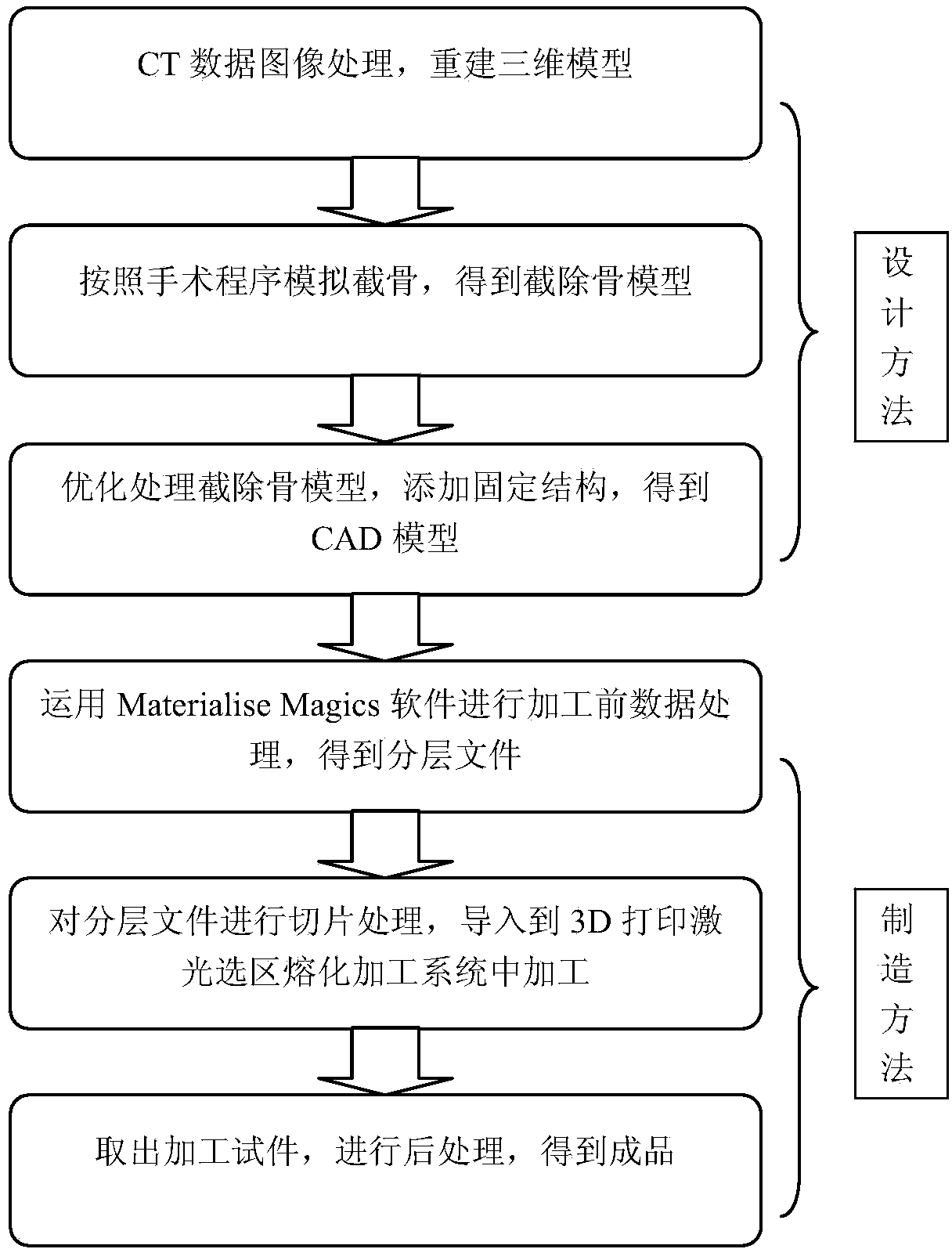

[0034] like figure 1 As shown, the personalized reverse design and manufacturing method of the total knee replacement prosthesis provided by the present invention comprises the following steps:

[0035] 1. Establish a three-dimensional digital model of the femur and tibia based on the medical imaging data of the patient's knee joint:

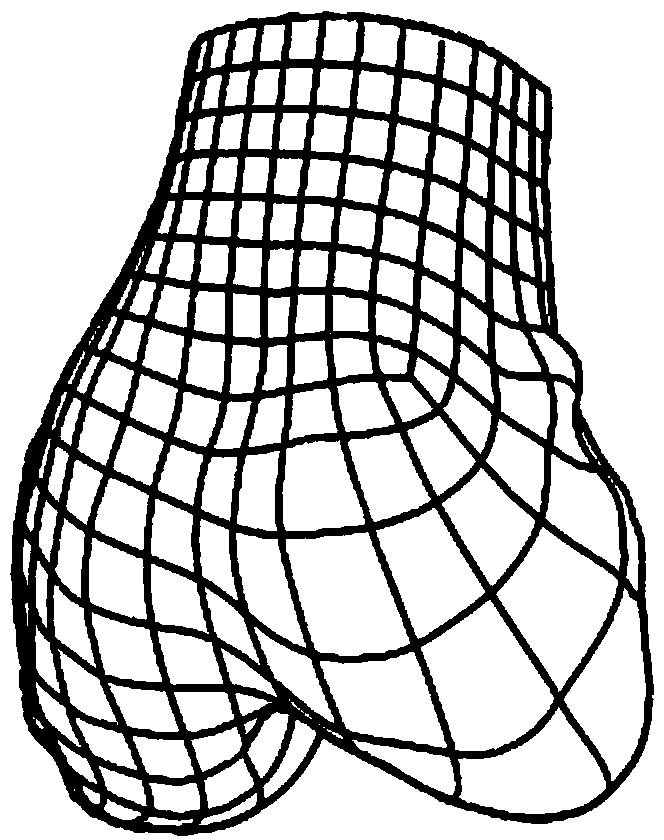

[0036] 1) Based on the CT / MRI tomographic scan image of the patient's knee femur in DICOM format, using the medical imaging software Mimics, the image is segmented and repaired according to the characteristics of different gray levels of soft tissue and bone in the image, and then 3D reconstruction is performed To obtain a three-dimensional digital model of the femur (such as figure 2 shown), and output as a PLY format file.

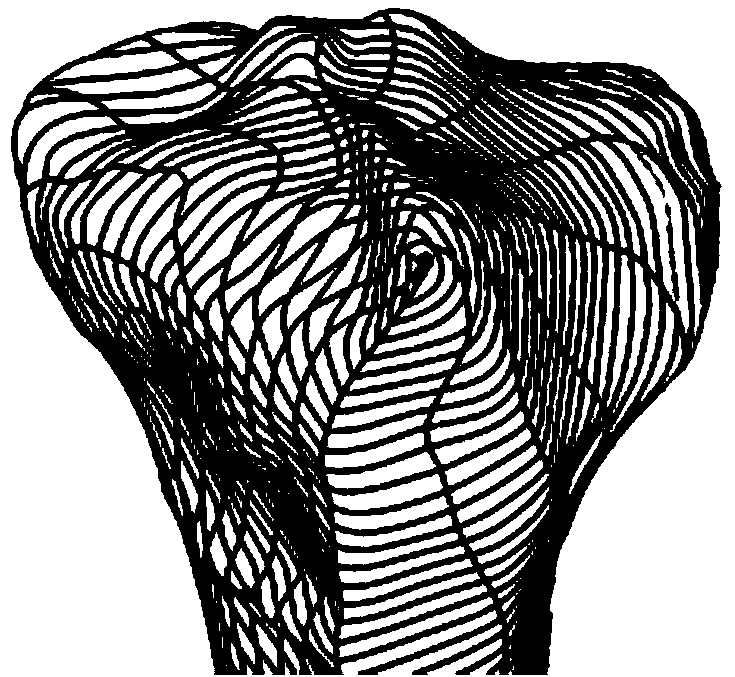

[0037]2) Based on the CT / MRI tomographic scan image of the patient's tibia in DICOM format...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com