Atomic layer deposition equipment

A technology of atomic layer deposition and equipment, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of long time consumption, low production capacity of atomic layer deposition equipment, and reduced production capacity of atomic layer deposition equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the atomic layer deposition equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

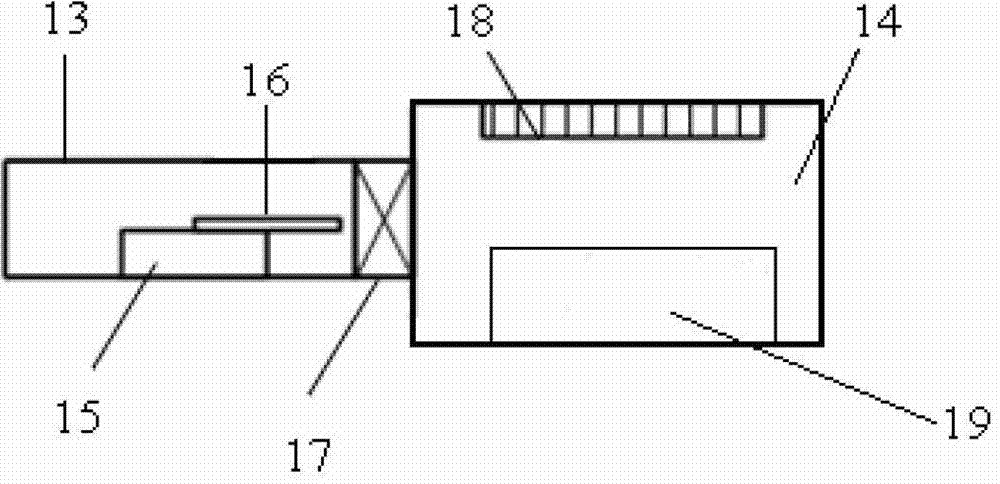

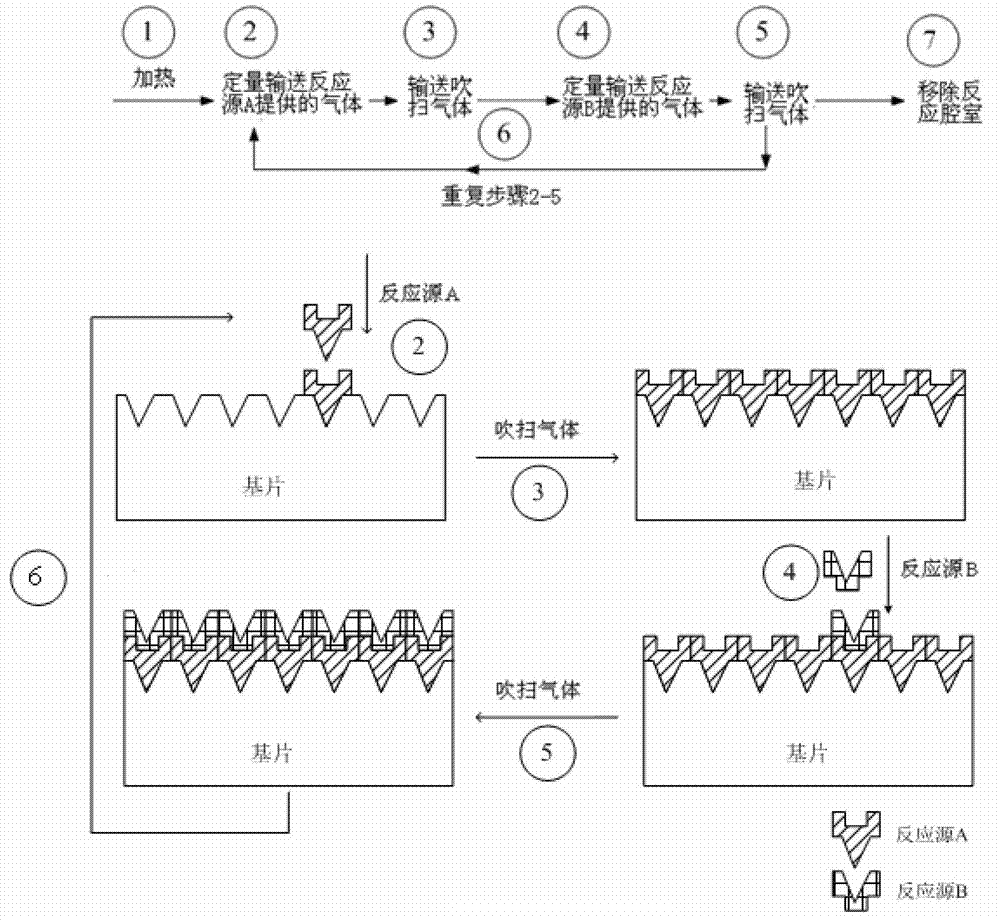

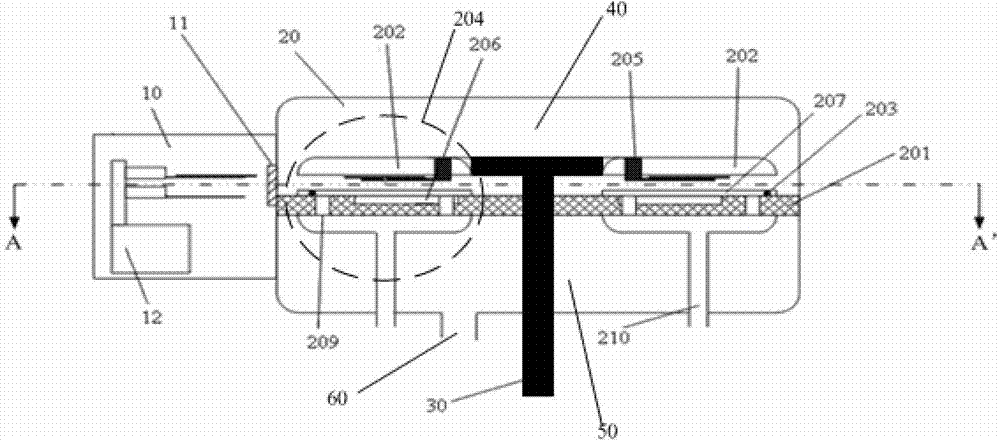

[0052] Figure 3A It is a cross-sectional view of the atomic layer deposition equipment provided by the first embodiment of the present invention. Figure 3B for Figure 3A A top view along the line A-A' in the center. Figure 3C for Figure 3A Top view of the middle and lower cover. Please also refer to Figure 3A , Figure 3B and Figure 3C , the atomic layer deposition apparatus includes a loading chamber 10 , a gate valve 11 and a reaction chamber 20 . Wherein, the reaction chamber 20 includes a plurality of sub-chambers and a driving unit 30, wherein four process positions 204 are arranged on the same horizontal plane (that is, a plane parallel to the upper surface of the substrate 201) in the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com