Fixture for assembling and welding universal crane arm standard knot

A technology of welding tooling and standard joints, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of waste of raw materials, money and time, difficult control of welding deformation, large dimensional error, etc., and achieve improvement Improve assembly quality, reduce out-of-tolerance deformation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

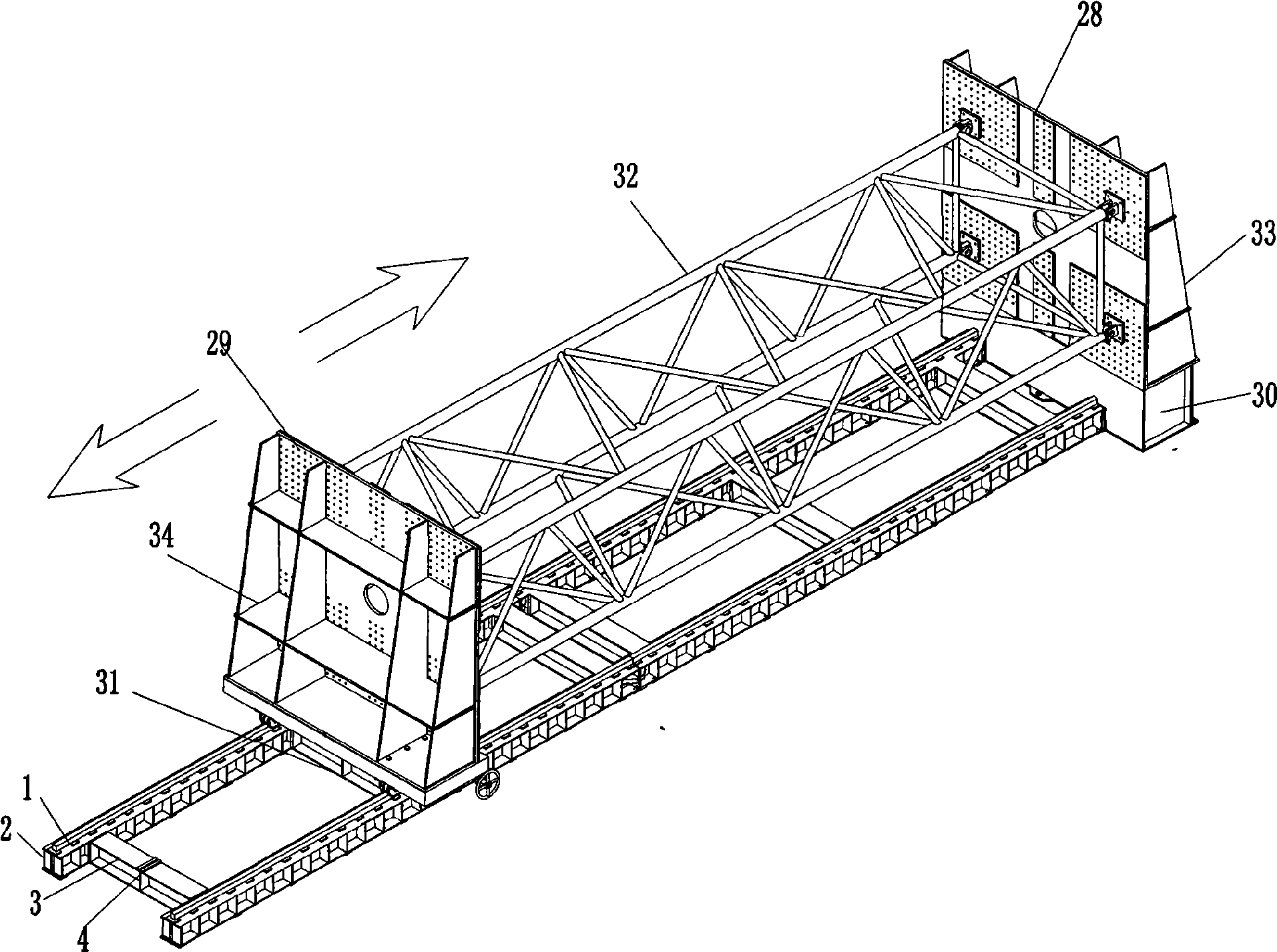

[0035] The following is an installation example of the A-type jib standard section, which is a kind of rectangular section crane jib standard section.

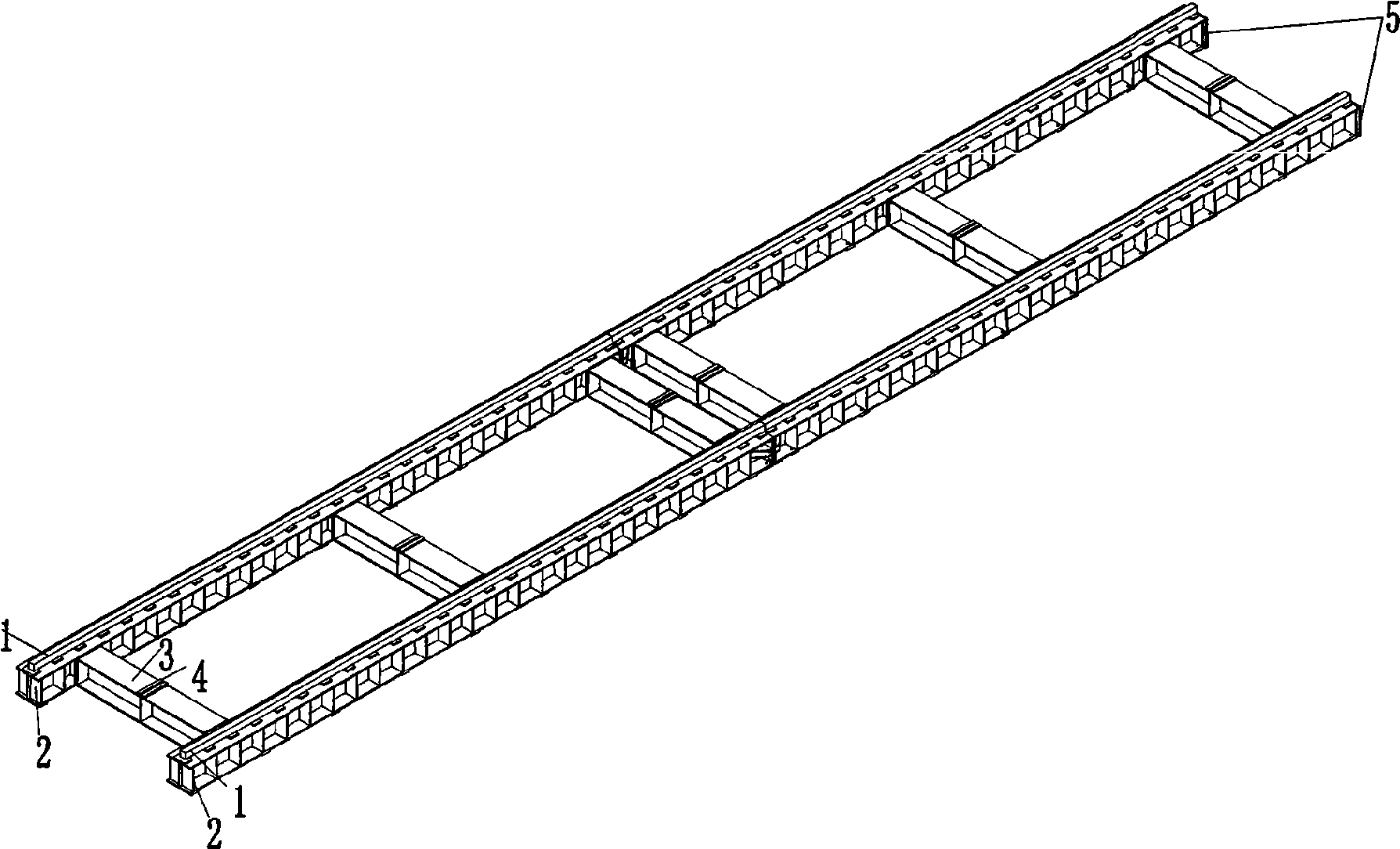

[0036] Place the base on a horizontal surface, connect the rail device through the positioning groove 4 of the base positioning standard plate, and then fix it through the base positioning standard plate 11 and the rail connecting plate 5, and measure the parallelism between the two rail devices After adjustment, the track connecting beam 3 is embedded between the two track devices and installed to ensure the parallelism size between the two track devices. Then measure the parallelism and levelness of the whole track 1 and after the size adjustment is completed, the whole track 1 is connected to the ground with bolts through the fastening bolt holes of the foot.

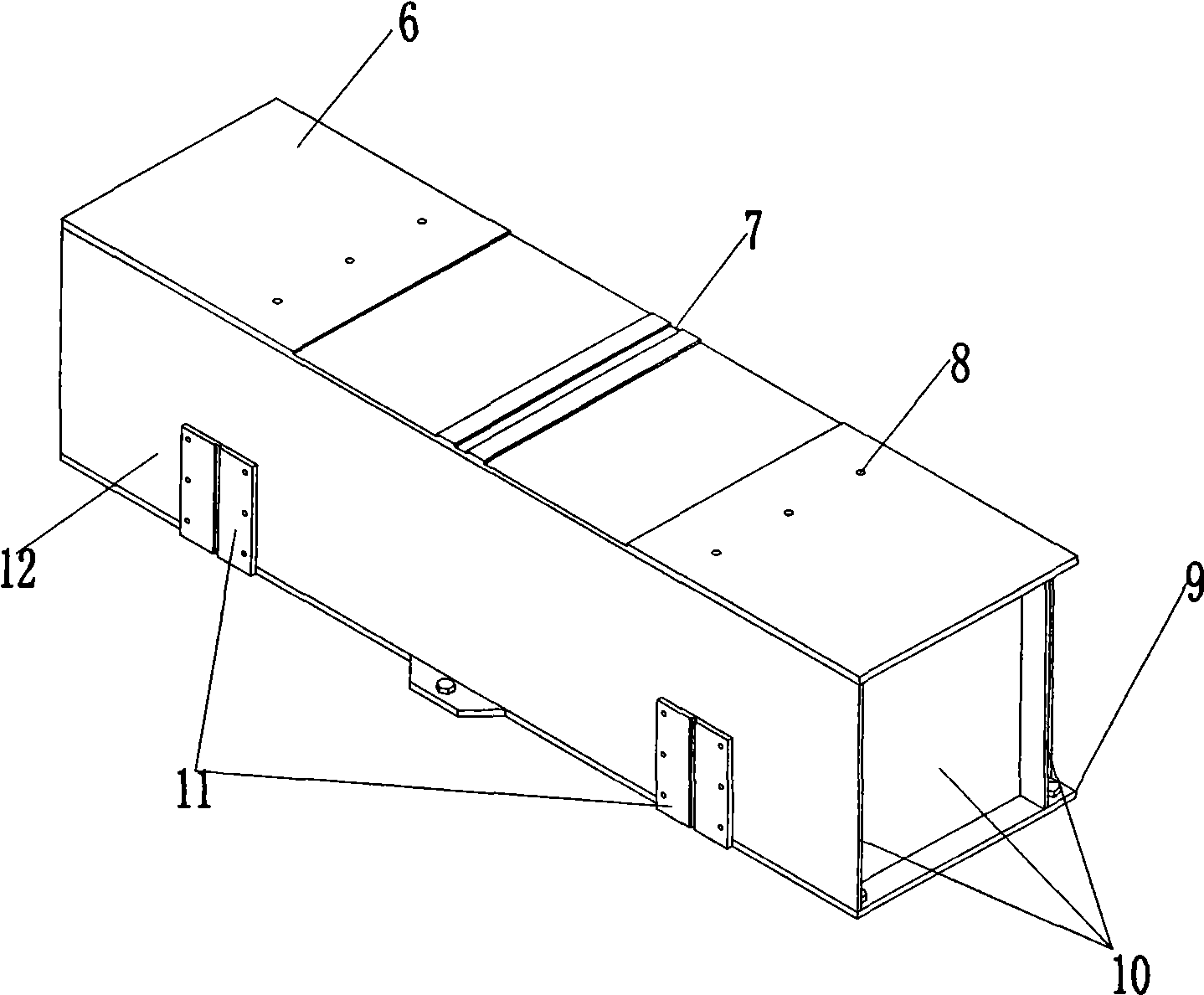

[0037] The trolley is installed on the track 1 through the groove of the walking wheel 21, so that it can slide on the track 1 parallel to the horizontal plane throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com